Maintaining and repairing outdoor power tools can often seem daunting, especially when you’re unsure about the specific parts that need attention. Having a clear reference guide can make the process much simpler, whether you’re performing routine maintenance or replacing a faulty component.

Knowing how each element fits together and functions within the system is crucial for effective repairs. With a well-structured visual reference, it becomes easier to identify individual parts and understand their roles. This can save both time and money by ensuring that the right components are replaced or repaired.

In this guide, you’ll find valuable insights into the structure and functionality of the tool, along with tips on identifying common issues. Whether you’re an experienced technician or a DIY enthusiast, this information will help you keep your equipment in top shape and avoid unnecessary problems.

Understanding the Key Components of Your Equipment

When it comes to repairing and maintaining outdoor power tools, a clear understanding of how different elements work together is essential. Each component has a specific function that contributes to the overall performance of the machine. Familiarizing yourself with these parts helps ensure smooth repairs and proper maintenance.

Identifying the Main Units

In any piece of equipment, there are core units that handle the most important tasks. These include the engine, the drive system, and the control mechanisms. Each unit plays a vital role in ensuring the tool operates effectively. Knowing where these components are located and how they interact can help you troubleshoot issues with greater efficiency.

Common Troubleshooting Areas

While the tool is designed for durability, certain parts are more prone to wear and tear. Areas such as the starter assembly, fuel system, and cutting mechanism often require attention over time. Understanding the function of each unit within the system allows you to identify issues quickly and determine which part needs repair or replacement.

How to Use the Parts Diagram Effectively

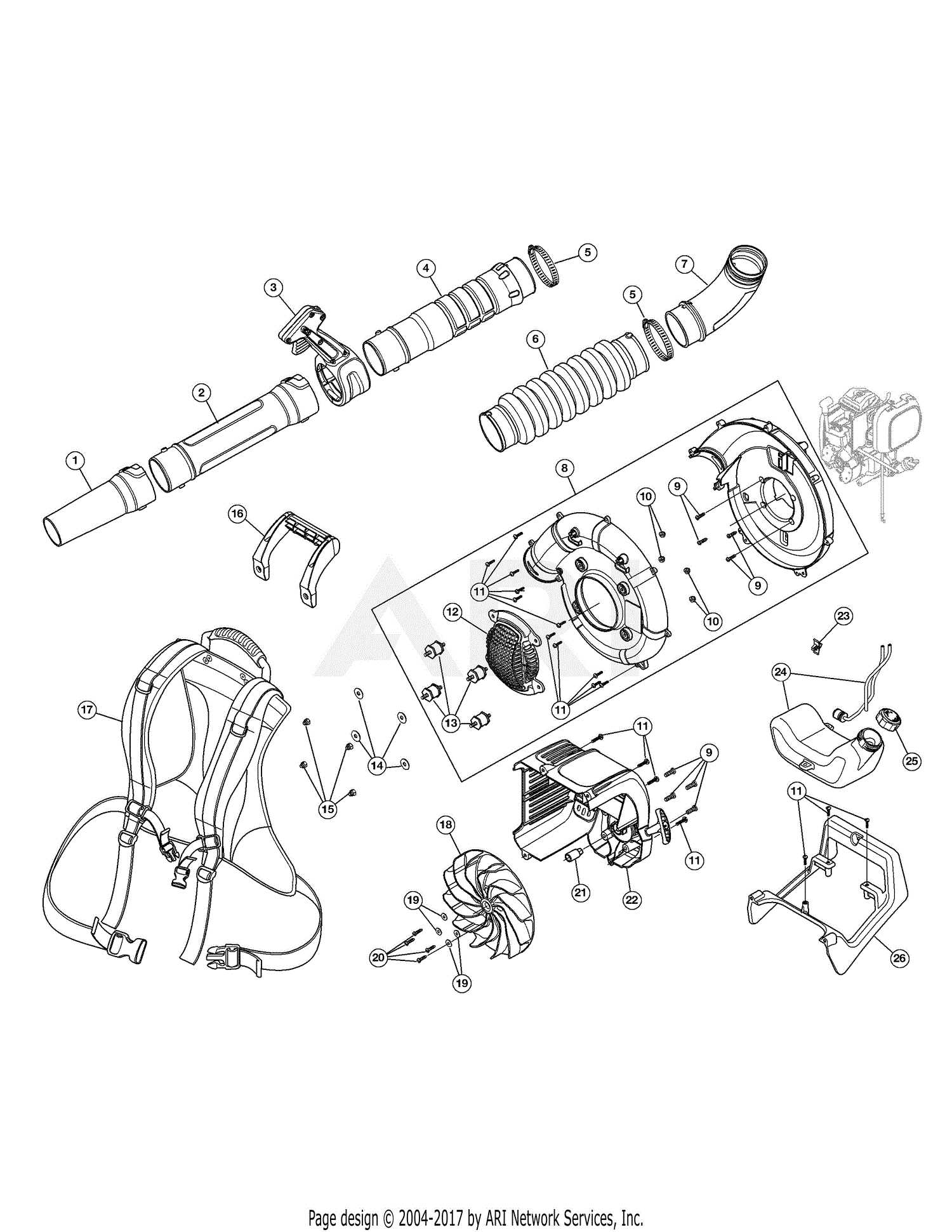

Having a visual reference for your equipment can significantly simplify the repair and maintenance process. A well-organized illustration allows you to quickly identify each component, understand its function, and see how it fits within the larger system. This tool is invaluable when it comes to pinpointing problems or ensuring you have the right parts for a replacement.

Interpreting the Visual Reference

When using a schematic, it’s important to first understand the layout of the components. Each part is usually labeled with a number or code, which corresponds to a list with further details. By following the diagram from start to finish, you can see how each element connects and interacts with others, making it easier to spot any missing or damaged pieces.

Finding the Right Component

Once you’ve familiarized yourself with the layout, use the diagram to pinpoint the exact location of the component you need. It is also helpful to check the part’s identification number to ensure you’re ordering or replacing the correct item. This reduces the chances of confusion and ensures that your repairs will be effective and long-lasting.

Common Issues and Replacement Tips

Even the most durable outdoor equipment can experience issues over time due to wear and tear. Understanding the most common problems and knowing how to properly replace worn-out components can help extend the life of your tool and ensure its optimal performance. Addressing these issues early can prevent more serious damage and costly repairs down the road.

Frequent Malfunctions

One of the most common issues is a malfunctioning starting system. Over time, the starter cord or recoil assembly can become worn or damaged. Another frequent problem involves the fuel system, where clogged filters or fuel lines can prevent the engine from running smoothly. It’s important to regularly check these components for any signs of wear or debris to maintain performance.

Replacement Tips for Long-Term Use

When replacing damaged or worn components, always ensure you’re using high-quality, compatible replacements. Using the wrong part can lead to further damage and reduce the tool’s efficiency. Take the time to carefully read the manufacturer’s recommendations and double-check that the replacement parts match your equipment’s specifications. Regular maintenance, including cleaning and lubricating moving parts, can also help prevent future issues.