Maintaining and repairing machinery requires a clear understanding of its individual components and their functions. Knowing how each part interacts helps ensure optimal performance and longevity of the equipment. This section focuses on providing valuable insights into the essential elements that make up your machine, offering guidance for troubleshooting and upkeep.

Whether you are replacing a worn-out component or conducting routine checks, having a clear reference can simplify the process. With detailed visual aids and thorough explanations, you’ll gain confidence in handling maintenance tasks efficiently. Pay attention to each part’s role and learn how they contribute to the overall operation of your equipment.

Understanding the structure and layout of the machinery is key to addressing common issues and extending its service life. By familiarizing yourself with these elements, you can better prepare for future repairs and optimize your machine’s performance. This knowledge empowers you to perform tasks with precision and avoid unnecessary complications.

Understanding the Equipment Components

Every machine is built from a collection of individual elements, each playing a crucial role in its overall function. Familiarizing yourself with these key elements is essential for efficient operation and effective maintenance. Understanding how these components work together will help you identify issues and perform repairs when necessary.

The key to successful upkeep is recognizing how each part contributes to the overall system. Whether you’re dealing with mechanical, electrical, or structural components, each has a specific purpose that aids in the machine’s operation. By gaining a deeper understanding of their functions, you ensure smoother performance and fewer breakdowns.

Proper maintenance requires knowing where and how each part fits within the assembly. Once you have a clear grasp of the layout, it becomes easier to troubleshoot problems, replace faulty elements, and keep your equipment running smoothly. This approach minimizes the risk of damage and optimizes the machine’s longevity.

How to Read the Equipment Blueprint

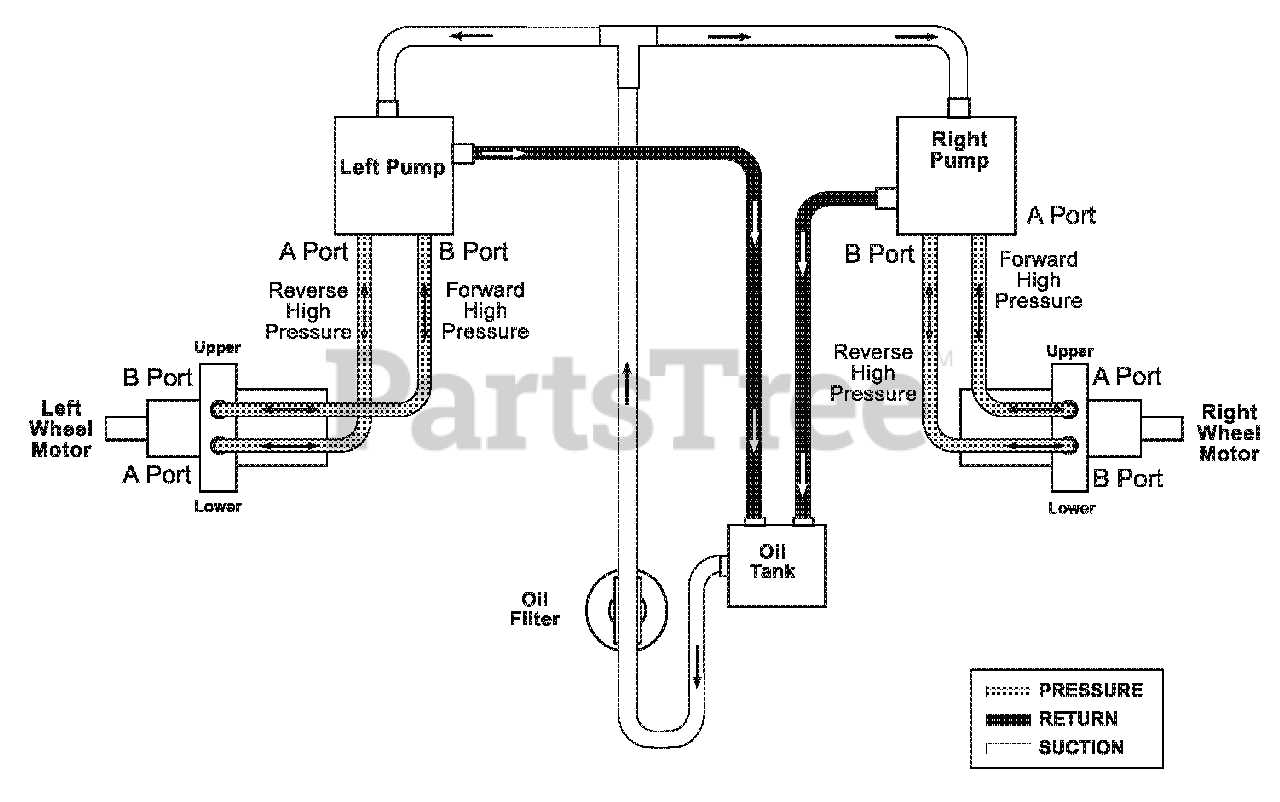

Understanding the layout of your machine requires careful attention to the blueprint that outlines its various components. A well-organized reference can provide clarity on the positioning and relationship between each element, helping you to visualize the overall structure. The key to reading such a guide lies in interpreting the symbols, labels, and connections accurately.

Focus on recognizing the main sections and their corresponding parts. Each part will typically be represented by a distinct symbol or shape, often accompanied by a label for easy identification. These references will guide you through the placement and alignment of components, which is essential when assembling, disassembling, or repairing the equipment.

To effectively use this resource, follow the flow from one section to another, paying attention to how components are connected. Understanding the direction of movement and interaction between parts will help in diagnosing potential issues and identifying the root causes of problems. A clear understanding of this visual guide will improve your troubleshooting skills and enhance your ability to maintain the machine.

Key Components for Machine Maintenance

Maintaining the longevity and efficiency of your equipment relies on understanding which elements need regular attention. Certain components are more prone to wear and tear and should be checked frequently to ensure proper operation. Identifying these key elements allows for proactive maintenance and reduces the likelihood of major breakdowns.

Engine and Power System

The engine is the heart of the machine, and keeping it in optimal condition is essential. Regular checks on the fuel system, ignition, and cooling components will prevent overheating and ensure smooth operation. The power system should also be inspected for any signs of wear or malfunction, as these issues can directly affect performance.

Transmission and Drive Components

Transmission parts are crucial for transferring power from the engine to the wheels or other mechanisms. Lubricating these components and checking for signs of damage can help prevent unnecessary wear. The drive system, including belts and pulleys, should also be inspected regularly to ensure there is no loss of power transmission or potential failure.