When it comes to the upkeep of complex machinery, knowing the exact components and their arrangement is essential for efficient repairs and replacements. A comprehensive overview of the internal structure ensures you can identify issues quickly and address them accurately. Familiarity with each part allows users to perform maintenance with greater confidence and precision.

Detailed visual aids play a crucial role in simplifying the process of recognizing different elements within the system. These resources offer clear references, making it easier to troubleshoot or enhance the functionality of your equipment. With a structured guide, understanding the system becomes less daunting, ensuring better care and long-term performance.

Investing time in understanding the internal workings not only reduces downtime but also contributes to a more sustainable operation. The clearer the understanding of the individual components, the more effectively one can maintain and optimize the overall system, ensuring its longevity and reliability.

Understanding the Equipment Layout

Having a clear understanding of the internal structure and components of any machine is essential for efficient operation and troubleshooting. Each element plays a crucial role in ensuring smooth functionality, and recognizing how they interact can make identifying issues much simpler. Proper familiarity with the arrangement allows for effective maintenance and quicker identification of any malfunctions.

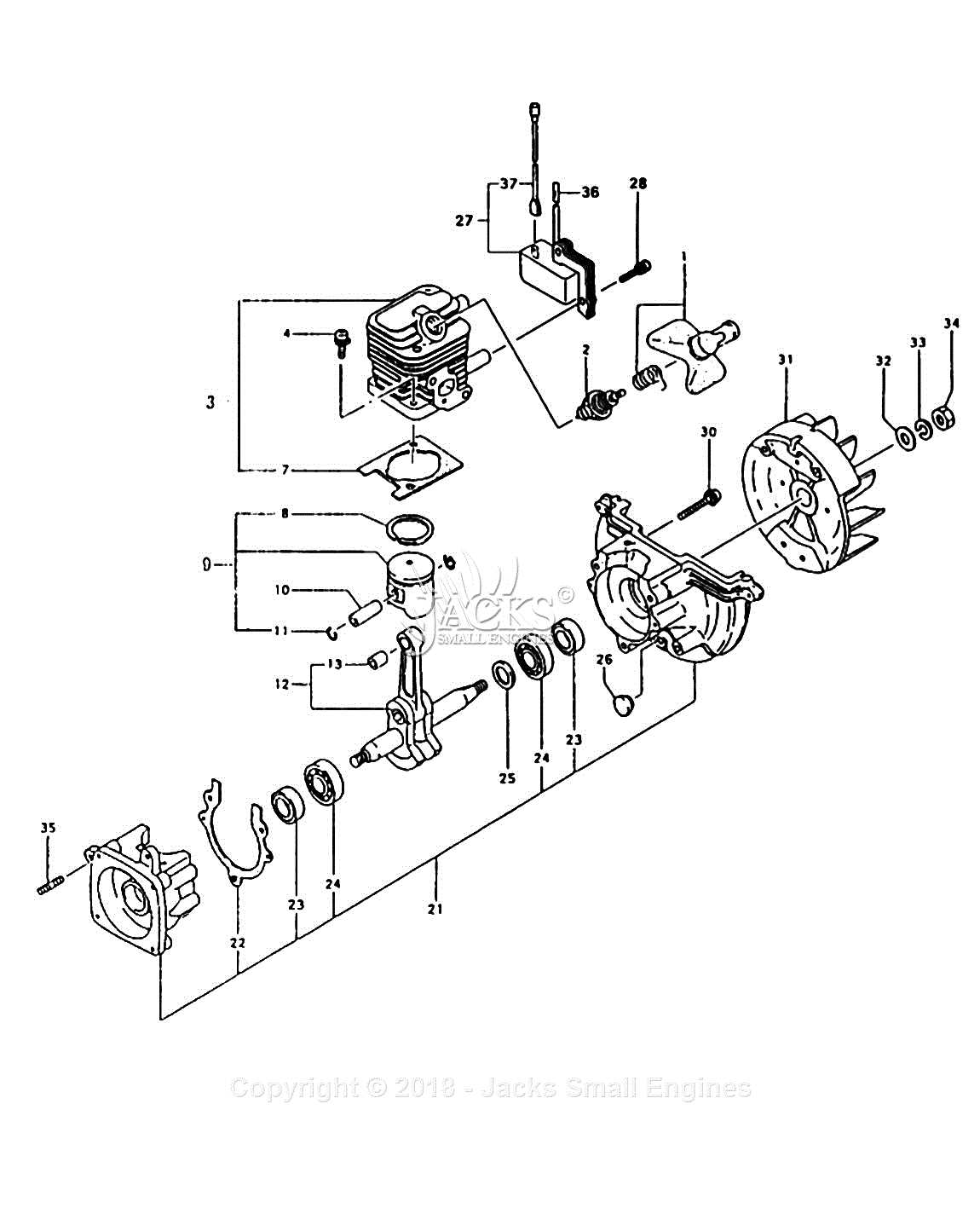

Detailed illustrations offer valuable insights into how the system is assembled, helping users visualize the parts in relation to each other. Such visual aids make it easier to pinpoint specific areas that require attention. These tools are indispensable when performing repairs, as they provide a clear map of the system’s layout, reducing the chances of errors during maintenance.

By mastering the layout and organization, operators can improve the overall performance of the machine. Knowing exactly where each component resides ensures faster repairs, more informed decision-making, and less downtime. Understanding the full configuration ultimately leads to a more reliable and durable machine.

Key Components of the Equipment

Every machine is composed of several crucial elements that work together to ensure its optimal performance. These key components are fundamental for the overall operation and should be thoroughly understood to manage maintenance and repairs efficiently. Knowing the role and function of each element helps prevent issues and reduces the likelihood of system failures.

The system is built with a variety of interconnected parts, each contributing to its operation. From the power source to the control mechanisms, understanding the relationship between these components is essential for smooth functionality. Regular inspection and knowledge of how each part functions ensure timely interventions when problems arise.

By becoming familiar with the core elements, users can identify wear and tear early and perform necessary actions to prolong the life of the machine. These vital parts ensure that the system operates efficiently and effectively, ultimately enhancing the user experience and minimizing downtime.

How to Identify Components on the Equipment

Recognizing each element within a complex system can be a daunting task, but with the right approach, it becomes manageable. The key to efficient maintenance lies in understanding where each component fits and how it functions. Once you know how to identify each part, you can troubleshoot and repair with more confidence and precision.

Here are some tips for identifying components:

- Start with the manual – Review the detailed guide to familiarize yourself with the general layout and key components.

- Use visual references – Look for labeled diagrams or images to match components with their physical locations.

- Examine the shape and size – Often, the form and scale of a component can give clues about its function within the system.

Once you’ve identified the elements, it’s essential to understand their connections and how they interact with one another. Recognizing common indicators such as screws, bolts, or specific markings on parts can greatly assist in identifying the correct components during maintenance.

By systematically reviewing these elements, you’ll be able to spot any faulty or worn-out parts more efficiently. This not only speeds up repairs but also helps maintain the machine’s longevity.

Visual Guide to the Components

Having a visual reference for understanding the internal structure of any machine can significantly enhance the repair and maintenance process. Visual aids such as illustrations or pictures help you better understand how each component is situated and how they work together. These guides simplify the identification of individual parts and their respective functions, making troubleshooting much easier.

Using a visual guide, you can quickly locate each element within the system, allowing you to pinpoint any issues or necessary replacements. The layout of such guides typically breaks down complex systems into more manageable sections, offering a clearer perspective on how everything fits and functions.

With the help of these guides, users can avoid errors during maintenance and reduce the risk of missing critical issues. By aligning the visual reference with your hands-on work, you ensure greater accuracy and efficiency in your repairs.

Maintaining Your Equipment Layout

Proper care and maintenance are essential to ensuring the long-term functionality of any machine. By regularly inspecting and servicing the internal components, you can avoid costly repairs and extend the lifespan of your equipment. Understanding how each element works and how they interact with each other is crucial for effective maintenance.

Routine maintenance involves checking for wear, cleaning, and replacing any worn-out components. It also includes keeping track of the assembly to ensure that everything remains in its correct position. Regularly referencing your equipment’s layout will help you spot potential issues early, preventing them from turning into bigger problems.

By staying proactive with maintenance and keeping an eye on the system’s health, you can maintain optimal performance and avoid unnecessary downtime. Knowledge of the internal configuration allows for quicker assessments and more efficient repairs when needed.