Every complex system consists of various interconnected elements that work together to achieve optimal performance. In the world of industrial equipment, having a clear understanding of these components is crucial for ensuring smooth operation and long-term durability. By examining the individual pieces, one can better grasp how each contributes to the overall function.

Maintenance and repairs are essential aspects of keeping any tool in good condition. Knowing the structure and function of each component helps users identify potential issues early and make informed decisions about repairs or replacements.

Efficient troubleshooting starts with understanding how parts interact. This knowledge allows operators to quickly diagnose problems and take appropriate action, reducing downtime and improving productivity in the long run.

Understanding the Components of Welding Machines

The operation of a complex tool depends on the seamless interaction of its individual elements. Each component, no matter how small, plays a vital role in the overall functionality and efficiency of the system. A deeper understanding of these key elements is essential for ensuring optimal performance and quick troubleshooting when issues arise.

Key Elements and Their Functions

The primary components in these systems are designed to handle specific tasks. These include energy conversion, controlling temperature, and regulating power flow. Each element must work harmoniously with others to maintain the right balance between power and precision. By recognizing how they function together, operators can ensure that the entire system operates smoothly and reliably.

Importance of Regular Maintenance

Maintaining the integrity of these components is essential for prolonging the life of the equipment. Regular inspection allows users to detect wear and tear or potential faults that could disrupt the operation. Early detection of issues can save time and money on more extensive repairs, making maintenance an integral part of ensuring continuous functionality.

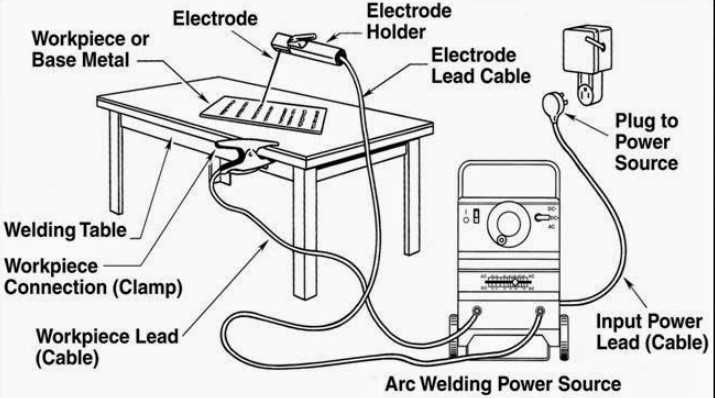

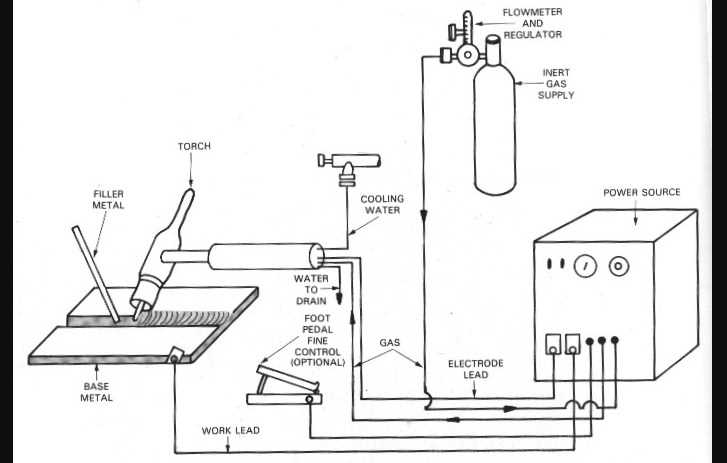

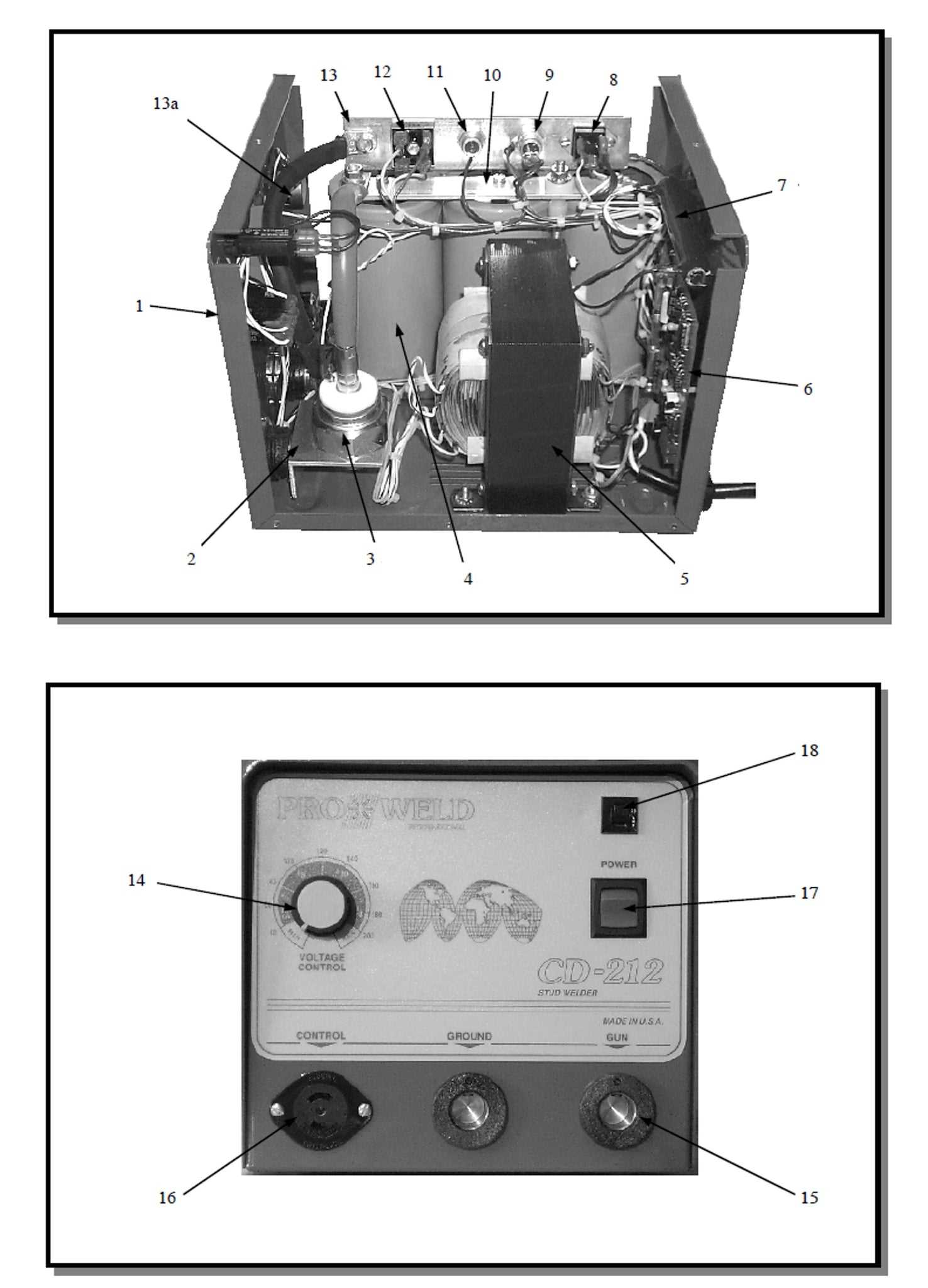

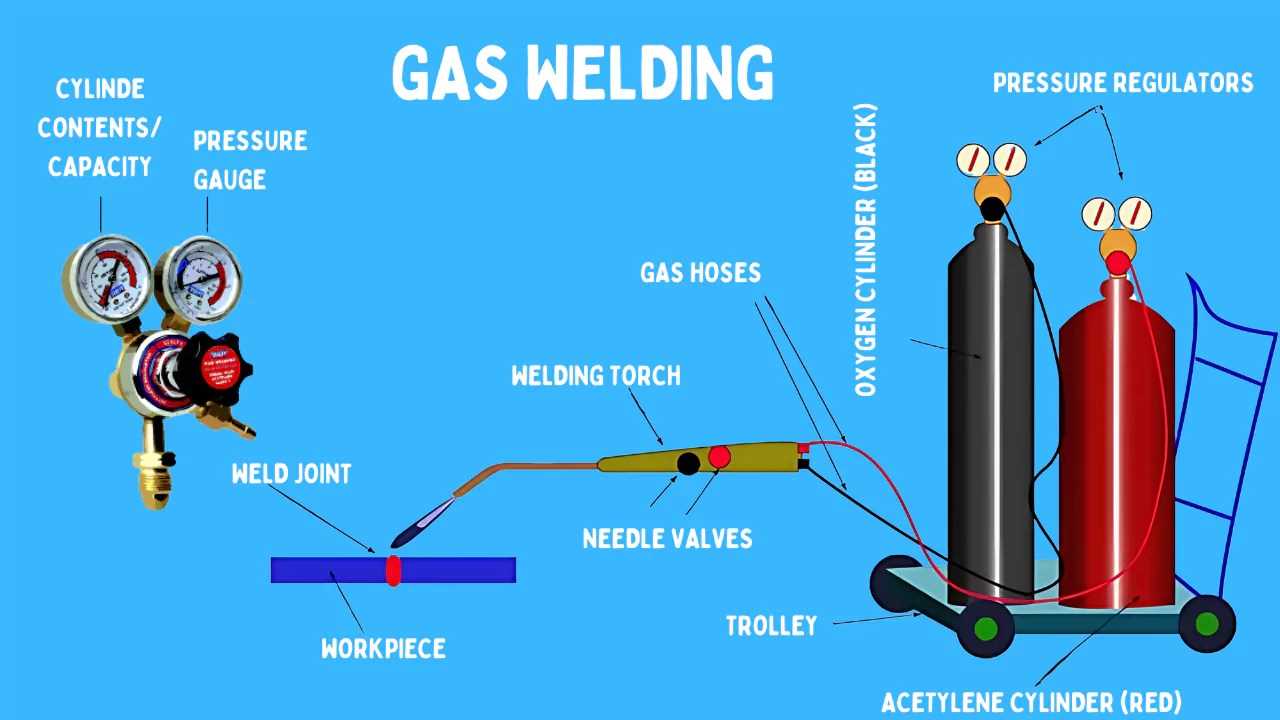

How to Read a Welding Machine Parts Diagram

Understanding the structure of any technical system begins with analyzing its visual representation. These illustrations provide a clear overview of the components and their connections. By interpreting these drawings, users can identify the exact location and role of each element within the larger system.

Identifying Components and Symbols

Technical drawings often use specific symbols to represent different components. These visual cues make it easier to understand the function of each part without needing to rely on descriptive text. Key symbols such as arrows and lines indicate connections, while labels provide additional information, such as voltage or current specifications.

Following the Flow of Operations

Once the symbols are understood, the next step is to track the flow of operations. This involves seeing how each component contributes to the overall process. Flowcharts often accompany these visuals, guiding users through the sequence of tasks performed by the system, helping ensure that all steps are executed correctly and efficiently.

Common Issues and Maintenance Tips for Parts

All systems experience wear over time, especially when subjected to continuous use. Understanding common issues that arise in key components is essential for proactive maintenance. Identifying these problems early can prevent more severe damage and improve overall system reliability.

Frequent Issues with Components

One of the most common issues is the buildup of debris or corrosion, which can obstruct proper function. Overheating due to poor ventilation or damaged connectors is also a frequent concern. Identifying these symptoms early allows for quick fixes before they escalate into larger problems that affect the entire system.

Effective Maintenance Practices

Regular cleaning and inspection are the most effective ways to maintain these systems. Lubricating moving parts helps reduce friction and extends their lifespan. Additionally, replacing worn-out connectors and ensuring proper insulation can prevent electrical faults. Establishing a routine checkup schedule ensures all components remain in optimal condition for prolonged usage.