When dealing with complex mechanical devices, it is essential to have a clear understanding of how different elements interact. This guide provides a comprehensive overview of the internal structure and components that play a crucial role in ensuring smooth operation. Whether you are a technician, hobbyist, or someone interested in maintaining such equipment, having knowledge of its internal workings is key to effective troubleshooting and repairs.

Understanding each component and its function allows for better decision-making during maintenance or when replacement is needed. The process of identifying and locating various parts is vital for efficient upkeep and optimal performance. In this section, we will explore the different components that contribute to the overall functionality of these devices, making it easier to manage any potential issues.

Familiarity with the internal elements not only improves the user’s ability to maintain the equipment but also enhances their capacity to perform any required adjustments or repairs with confidence. By understanding the relationships between parts, users can ensure longevity and reliability in operation.

Understanding Key Mechanism Components

To properly maintain and troubleshoot mechanical systems, it is important to recognize the various elements that contribute to their function. Every device consists of several critical components, each with a unique role that ensures the entire system operates efficiently. Familiarizing oneself with these components allows for smoother repairs and better management of potential malfunctions.

Each component serves a specific purpose, from providing power to the mechanical elements, to supporting the overall structure. Understanding the interaction between these components helps in diagnosing issues more accurately, allowing for quicker fixes. By knowing the function of each element, users can ensure that the equipment performs at its best and avoid unnecessary breakdowns.

Properly identifying and learning about the essential components not only improves repair efficiency but also extends the lifespan of the device. With this knowledge, users can approach maintenance with confidence, knowing exactly which parts to check and replace when necessary.

Identifying Key Components in a Mechanical System

Understanding the layout and structure of a mechanical system is crucial for efficient troubleshooting and maintenance. Recognizing the key elements and their functions within the system allows for a clear approach to repairs and optimizations. This section explores how to identify the most important components that contribute to the overall performance of the equipment.

Locating the Core Elements

Each mechanical system consists of several main parts, each playing a specific role in its operation. From the power source to the supporting structures, understanding where each element is located can greatly simplify maintenance tasks. Proper identification of these elements ensures that repairs are made in the correct areas, preventing unnecessary work or damage.

Understanding Function and Interaction

Knowing how components interact with one another is just as important as identifying their physical locations. For example, one part may depend on another for proper functioning, and understanding this relationship allows users to diagnose issues more effectively. By learning the specific function of each part, users can make informed decisions during repairs or replacements.

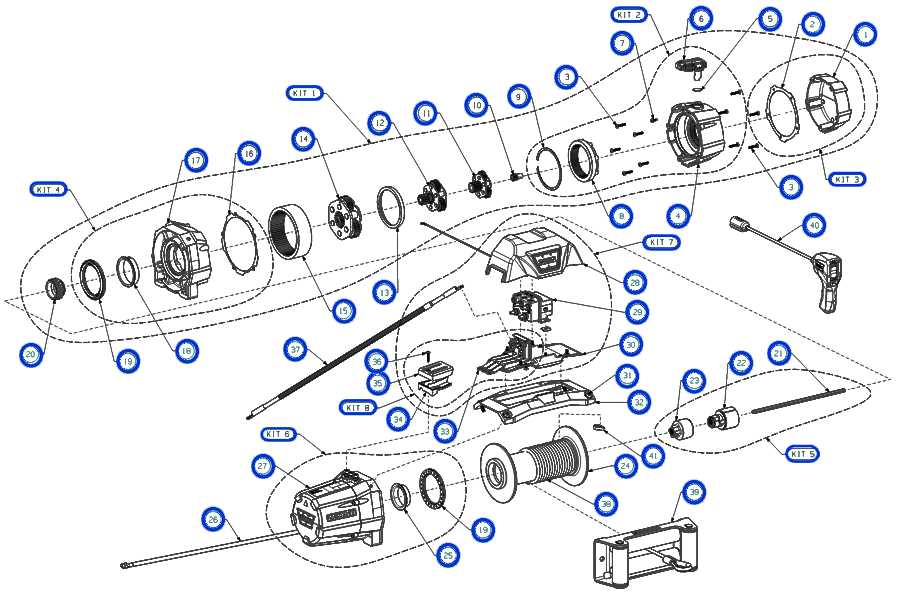

How to Use the Mechanical System Layout

Effectively utilizing a layout or schematic of a mechanical system requires understanding how to interpret its components and connections. Such visuals offer a clear representation of the system, making it easier to identify specific parts, their roles, and their relationships to one another. This section will guide you on how to use these schematics to troubleshoot, repair, and maintain the equipment efficiently.

By following the visual cues and symbols presented, you can pinpoint which elements require attention. The layout typically includes labels and arrows to show connections, which can assist in understanding the flow of power or movement through the system. Familiarity with these indicators enables users to approach maintenance with confidence and precision.

In addition to basic identification, understanding the layout allows you to quickly determine where issues may arise. Whether it’s a misalignment, wear, or faulty connection, knowing how to use the schematic helps in identifying the source of the problem without unnecessary disassembly. This methodical approach ensures quicker resolutions and minimizes downtime.