When it comes to maintaining and repairing small marine engines, a clear understanding of the individual components and their functions is essential. The reliability of any watercraft relies heavily on the performance of these engines, which require regular attention to ensure smooth operation. Knowing how the different parts fit together and work in harmony allows for more efficient troubleshooting and servicing.

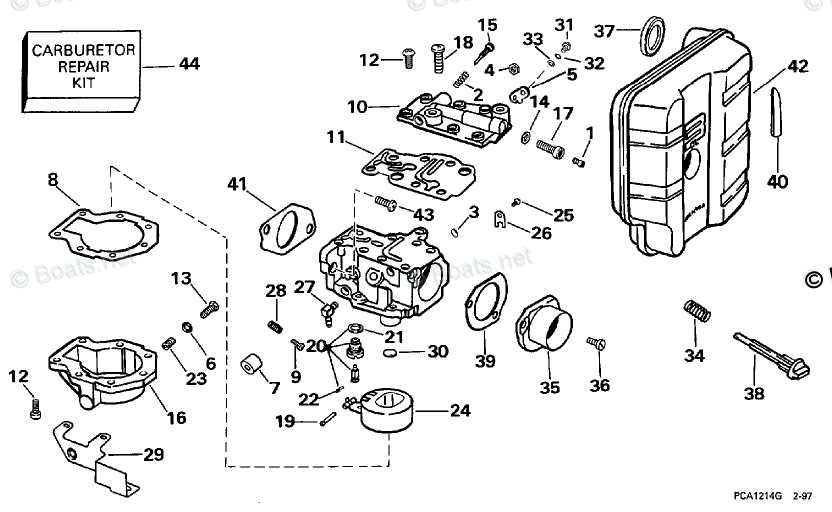

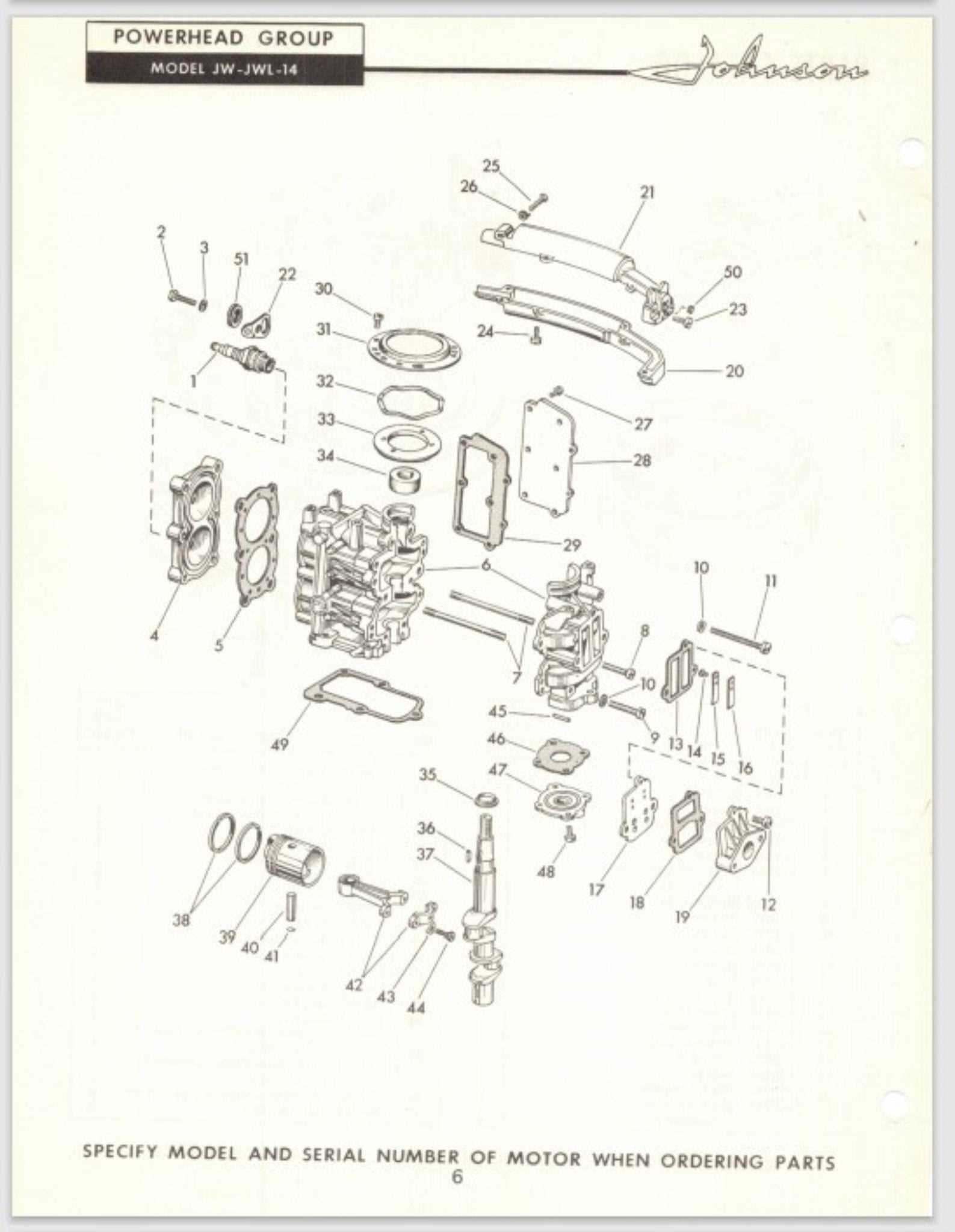

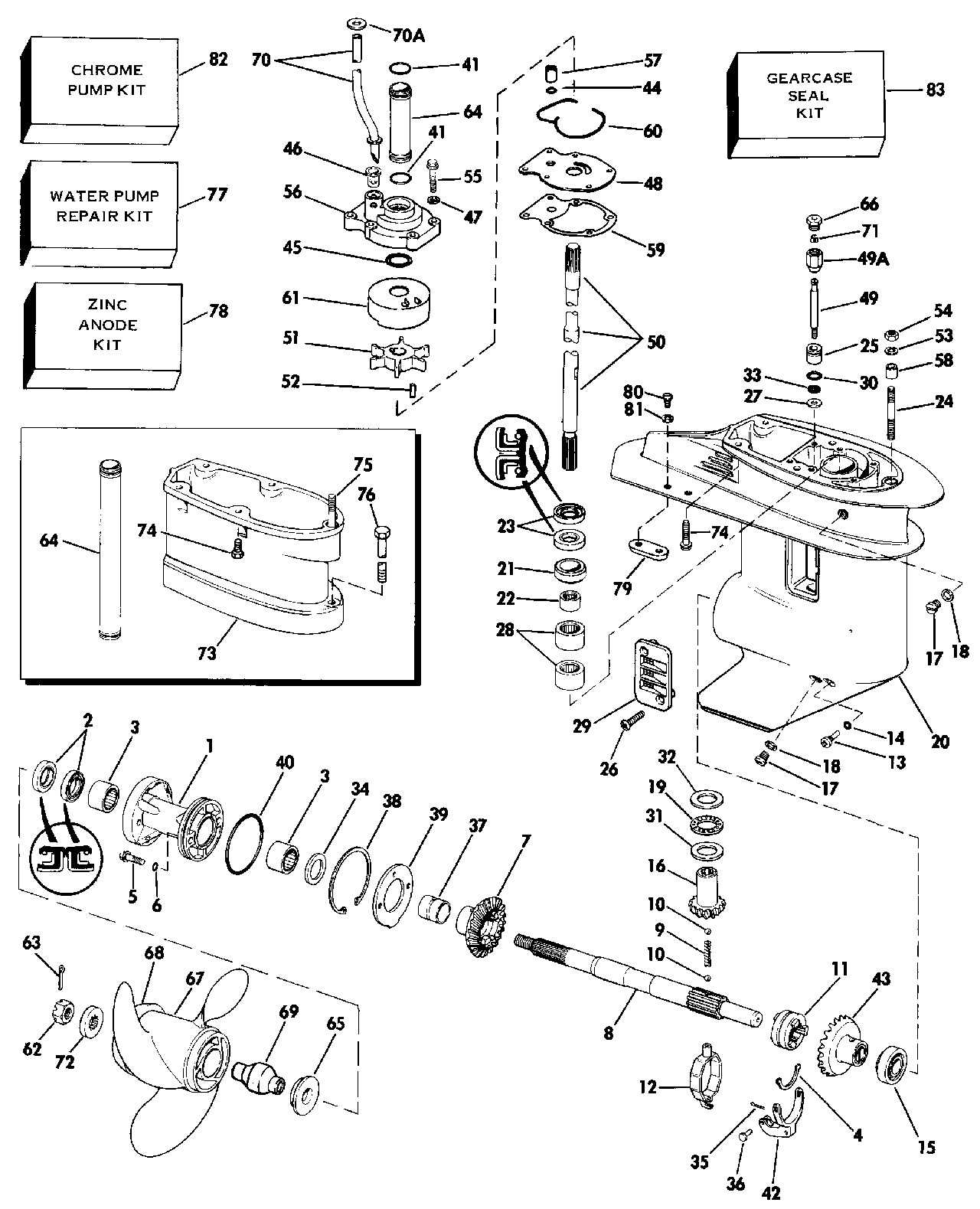

Proper identification and familiarity with the specific elements of the engine can make all the difference in quickly pinpointing issues. Whether you’re a seasoned professional or an enthusiast, having a visual representation of the engine’s layout can significantly enhance the repair process, helping you identify worn or damaged components without unnecessary guesswork.

By having access to detailed illustrations or schematics, you can ensure that each part is correctly assembled and functions as intended. This approach not only prevents future problems but also maximizes the longevity of your equipment, keeping it in top condition for years to come.

Understanding 25 HP Engine Components

For anyone working with a 25 horsepower marine engine, having a solid grasp of the individual components and how they interact is crucial. The performance and longevity of the engine depend largely on the proper functioning of each element, from the fuel system to the cooling mechanism. Recognizing how these pieces fit together helps in troubleshooting, maintenance, and repairs, ensuring that everything operates smoothly during use.

Key Engine Elements

The engine’s key components include the cylinder assembly, fuel delivery system, ignition system, and the exhaust mechanism. Each of these parts plays a vital role in ensuring the engine runs efficiently. The cylinder assembly houses the pistons, which are responsible for converting the power generated by the fuel combustion into mechanical force. The fuel delivery system ensures the right amount of fuel is mixed with air for optimal combustion, while the ignition system provides the spark needed to ignite the fuel-air mixture.

Maintaining Engine Efficiency

Regular maintenance of these systems is necessary to keep the engine running at peak performance. Over time, components like spark plugs, fuel filters, and cooling systems may wear out or become clogged, leading to reduced efficiency or even engine failure. By understanding the function and layout of these elements, owners can more easily identify issues and replace parts when necessary, extending the engine’s service life and preventing costly repairs.

Key Components in Marine Engine Models

In any marine engine, especially those designed for smaller vessels, the core components that drive its operation must be well understood. These essential elements ensure that the engine delivers power efficiently, performs optimally, and stands up to the demanding conditions of the water. Familiarity with the major systems and their roles is critical for anyone involved in maintenance or troubleshooting.

Major Engine Systems

The primary systems include the ignition, fuel, and cooling systems. The ignition system is responsible for sparking the fuel mixture and ensuring the engine fires correctly. The fuel system handles the intake and mixing of fuel with air, ensuring that combustion happens at the right time and with the right mixture for maximum power. The cooling system, often involving water circulation, prevents the engine from overheating by regulating its temperature during operation.

Essential Supporting Components

Supporting components, such as the propeller, transmission, and exhaust system, work in conjunction with the main systems to enable the engine to propel the vessel effectively. The propeller converts the power generated by the engine into forward motion, while the transmission allows for speed adjustments and gear changes. The exhaust system channels harmful gases out of the engine and away from the vessel, ensuring a safe and efficient operation.

How to Use Component Layout for Maintenance

Proper maintenance of any mechanical system requires a deep understanding of its structure and individual elements. One of the most effective tools in achieving this is a detailed layout that shows the arrangement and function of each component. This visual guide allows you to identify the parts needing attention, ensuring that maintenance tasks are completed accurately and efficiently.

Identifying Worn or Damaged Parts

By referencing a detailed layout, you can quickly spot any components that may be worn or damaged. This visual representation gives a clear idea of where each part is located, helping you to assess the condition of items such as seals, bearings, and gaskets. Being able to see the exact position of each element makes it easier to pinpoint areas that require replacement or servicing.

Ensuring Proper Reassembly

After completing maintenance tasks, it is important to reassemble all components correctly to ensure smooth operation. A layout serves as a helpful reference during this process, ensuring that each part is installed in its designated position. Following the guide closely helps avoid mistakes that could lead to poor performance or damage, ensuring the engine continues to operate efficiently.