The efficiency of an engine relies on the harmonious interaction of various elements that work together to ensure optimal performance. These elements are carefully designed to handle specific tasks that contribute to the smooth operation of the engine. Knowing how each part functions individually and in collaboration is essential for proper maintenance and troubleshooting.

Understanding the flow of fuel, air, and other vital substances through these components is crucial for anyone interested in improving their vehicle’s performance or tackling mechanical issues. Whether you’re a professional mechanic or a hobbyist, grasping how these elements are arranged and operate together can make a significant difference in repairs and upgrades.

Identifying potential problems and learning how each component supports the overall engine function will help in diagnosing issues and applying the right solutions. By studying the layout and functions of these elements, you can gain deeper insights into the heart of engine mechanics.

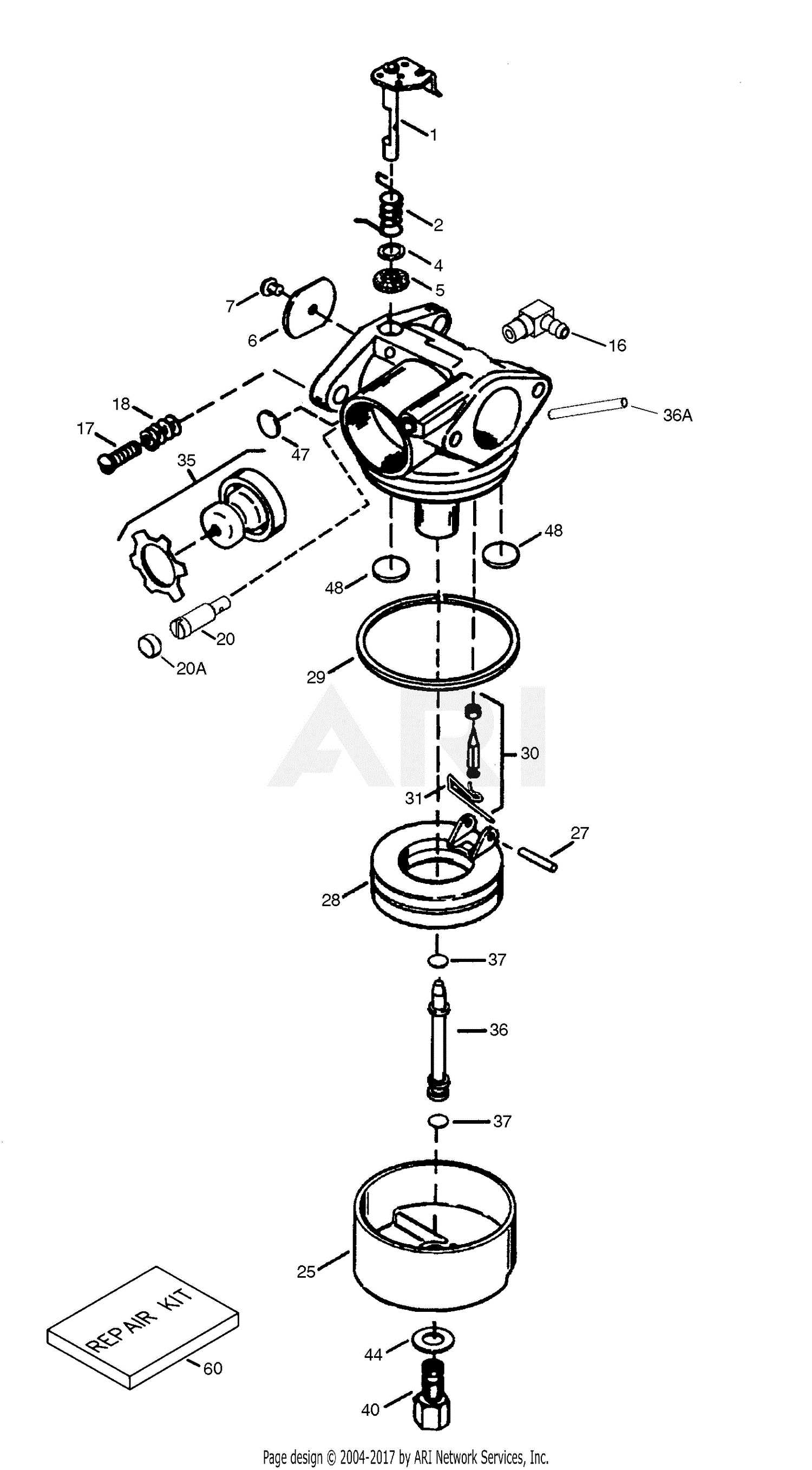

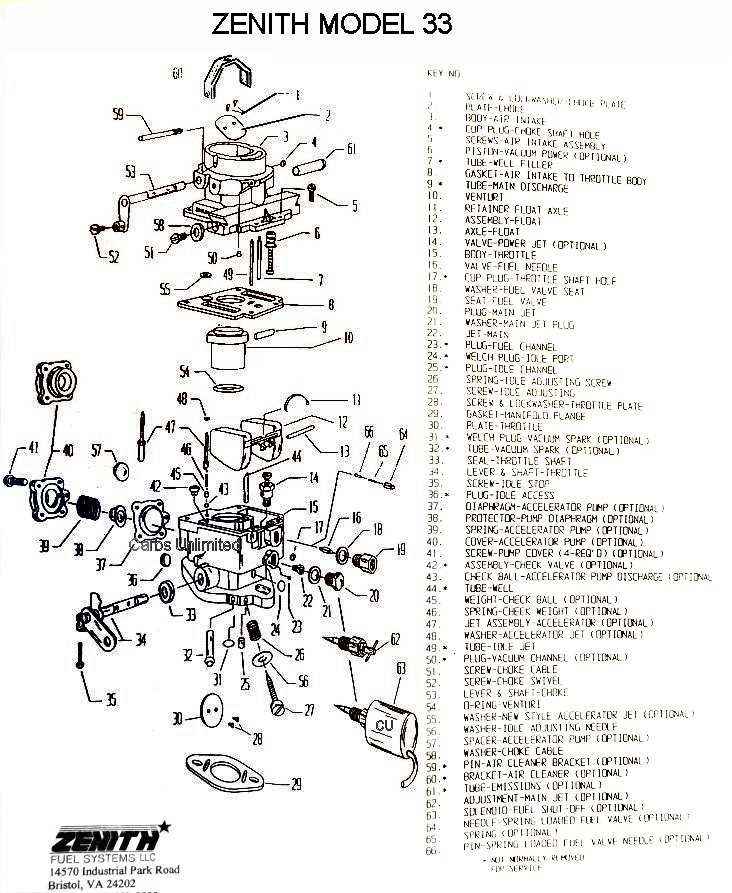

Key Components of a Carburetor

Engine performance is largely determined by the individual components that work together to regulate the fuel-air mixture entering the engine. Each element plays a specific role in controlling fuel flow, air intake, and the overall combustion process. Understanding the functionality of these components is essential for proper maintenance and ensuring efficiency.

The fuel bowl stores the fuel needed for combustion, maintaining a constant supply while the engine operates. The throttle valve controls the amount of air and fuel entering the engine, directly influencing engine speed. Meanwhile, the needle valve regulates the flow of fuel into the chamber, ensuring that the correct amount of fuel is available at all times.

Other essential elements include the choke, which helps start the engine by enriching the fuel mixture, and the venturi, which accelerates airflow to create a vacuum that draws fuel into the air stream. These key components ensure the engine operates smoothly and efficiently, providing the right balance for optimal performance.

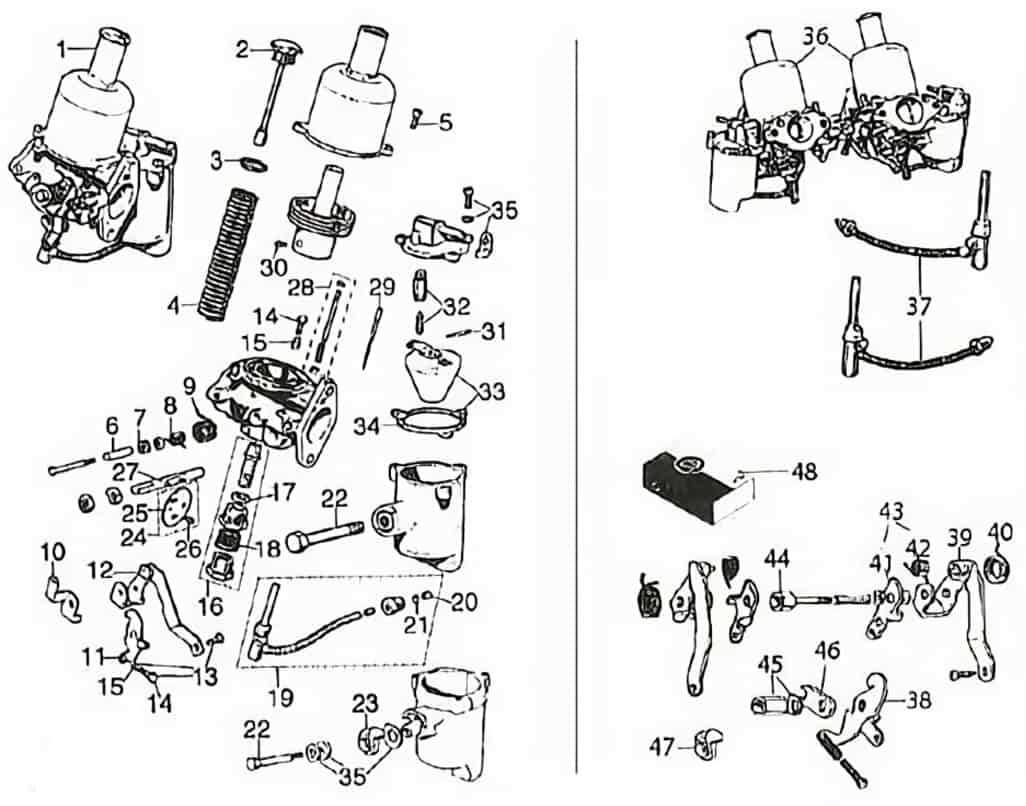

How Carburetor Parts Work Together

The components within the fuel system are intricately designed to work in unison, ensuring the engine runs efficiently under various conditions. Each part plays a crucial role in controlling fuel and air flow, which directly impacts the combustion process. Understanding how these elements collaborate helps in optimizing engine performance and diagnosing issues effectively.

The flow of air and fuel begins when the throttle valve adjusts the airflow into the system. As air enters, it passes through the venturi, where its speed increases, creating a vacuum that draws fuel from the fuel bowl. This mixture is then delivered to the engine, providing the necessary components for combustion. The needle valve ensures the correct amount of fuel is delivered, while the choke enriches the mixture when starting the engine, making it easier for the system to function at low temperatures.

When these components work together, they maintain a precise balance between air and fuel, allowing the engine to perform smoothly across a range of speeds and conditions. The coordination of these elements ensures that the system remains responsive, providing the right mixture for efficient power production.

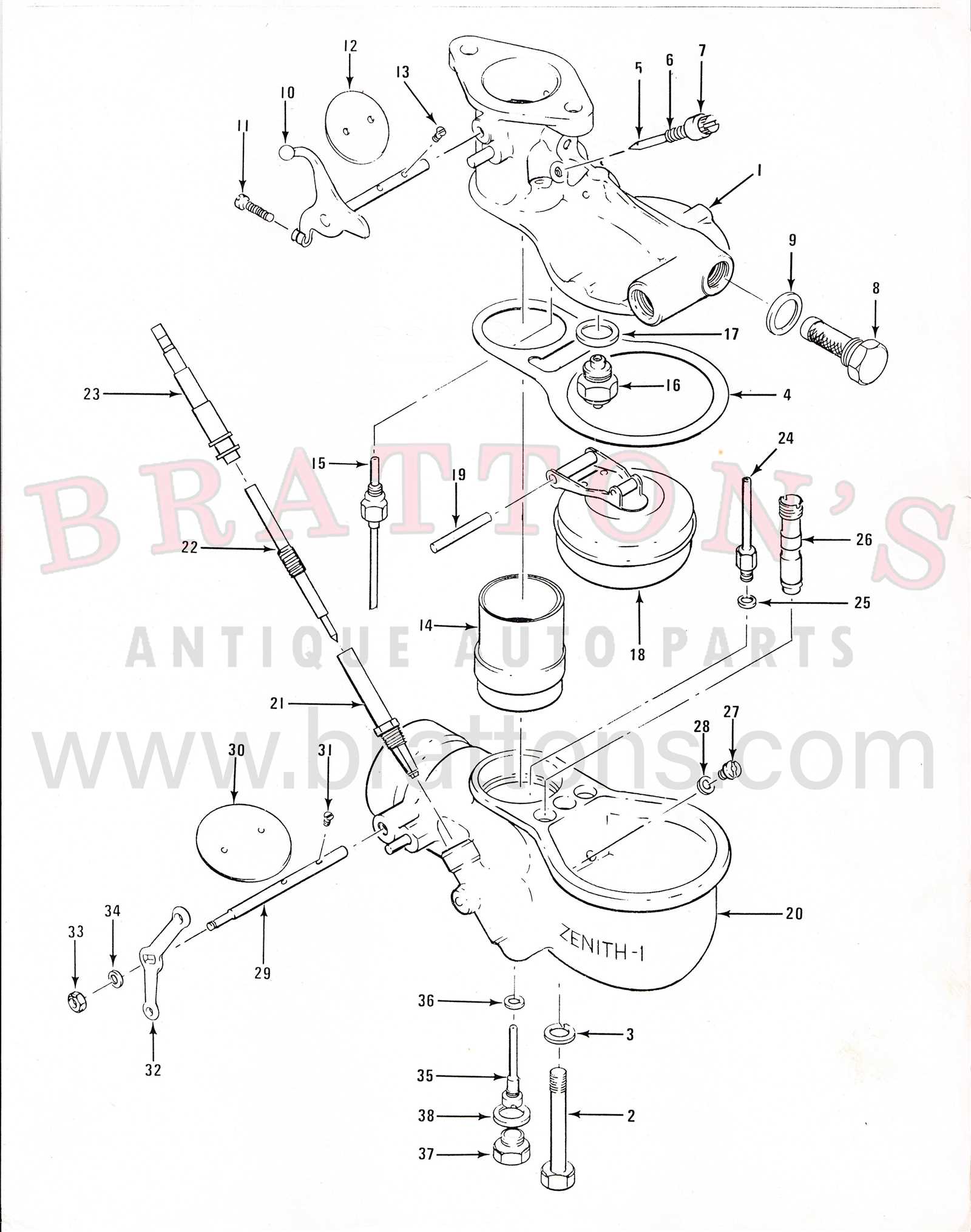

Common Issues with Carburetor Parts

Like any mechanical system, the components responsible for regulating fuel and air flow can experience wear and tear over time. Understanding the most common issues that can arise with these elements is key to maintaining optimal engine performance. Diagnosing problems early can prevent further damage and improve efficiency.

Fuel Flow Problems

One of the most common issues involves improper fuel flow, often caused by clogged jets or a malfunctioning needle valve. When these elements become obstructed, the fuel supply to the engine is disrupted, leading to poor acceleration, stalling, or difficulty starting the engine. Regular cleaning and maintenance are essential to prevent such blockages.

Airflow Restrictions

Air intake issues can also lead to engine performance problems. A malfunctioning throttle valve or venturi can result in insufficient airflow, which prevents the engine from receiving the correct air-fuel mixture. This can cause the engine to run too rich or too lean, affecting its power output and fuel efficiency.