When working on any machine, having a clear understanding of its internal components is essential for proper maintenance and repair. Identifying the right parts and knowing their function can greatly simplify troubleshooting and replacement tasks. For machinery enthusiasts and professionals alike, referring to detailed layouts can help in making informed decisions about repairs and upgrades.

Accurate identification of each element allows owners to ensure smooth operation, extend the lifespan of their equipment, and avoid unnecessary complications. With the help of a well-structured reference, operators can quickly locate specific elements, enhancing their ability to work more efficiently.

In this guide, we will explore how to navigate a comprehensive reference for your machine’s key components, providing essential information to aid in repairs and keep your equipment running at its best. Whether you’re a beginner or an experienced operator, understanding these resources can save time and reduce the cost of unnecessary repairs.

Understanding the Tractor Components

Familiarity with the individual components of any machine is key to maintaining its efficiency and performance. By understanding the various elements that make up the system, operators can identify potential issues early and address them before they lead to more serious problems. A thorough knowledge of these components allows for better decision-making when it comes to repairs and maintenance.

Each part plays a specific role in ensuring the machine operates smoothly. From the engine to the wheels, every component must be in optimal condition to avoid mechanical failures. Having a detailed understanding of these elements, as well as how they interact, enables owners to troubleshoot effectively and perform the necessary repairs or replacements with ease.

By using a visual reference, operators can easily locate and identify components that need attention. This ensures that maintenance tasks are carried out properly and that the machine continues to perform at its best for years to come. Understanding the layout of the components allows for a more efficient approach to both preventative care and corrective measures.

How to Read the Parts Diagram

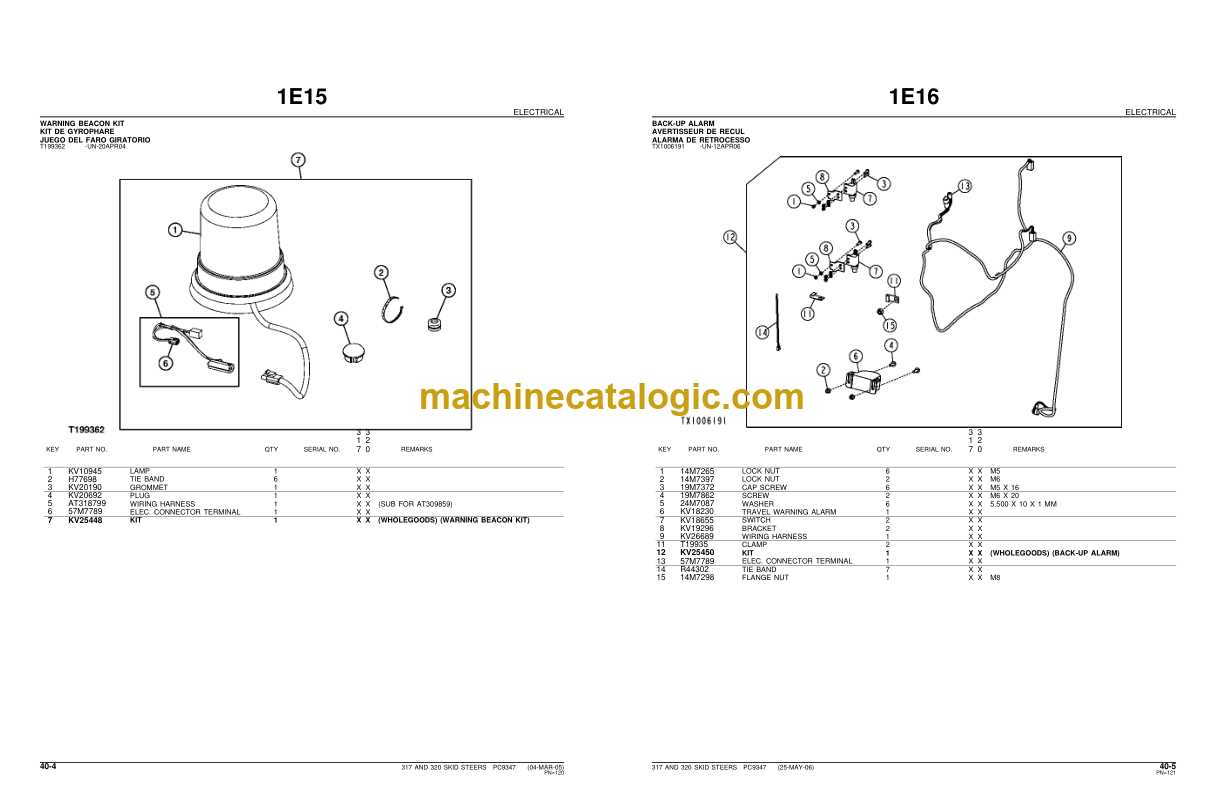

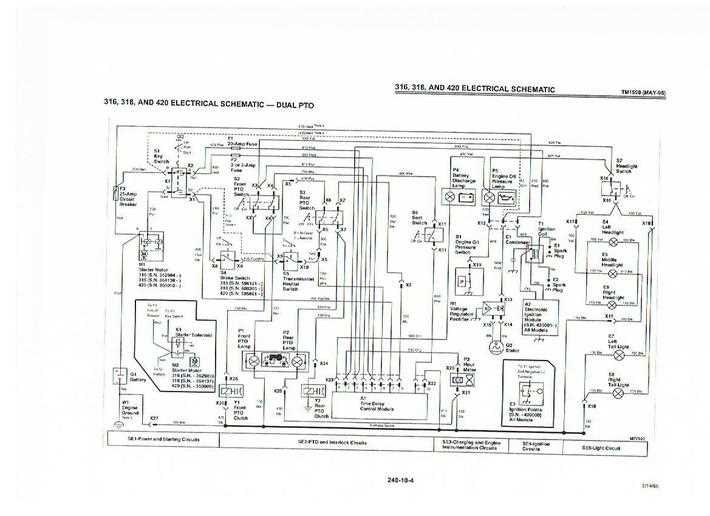

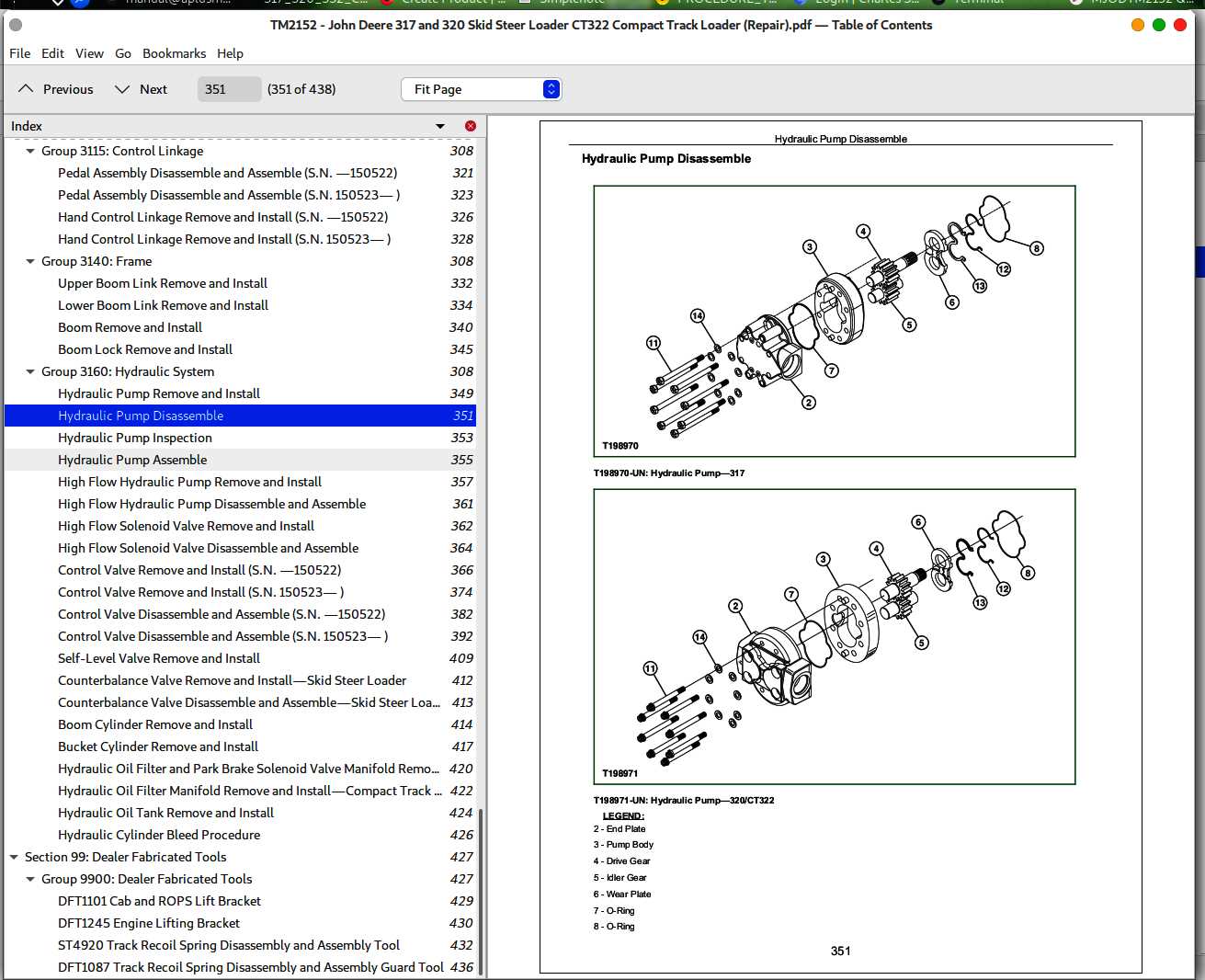

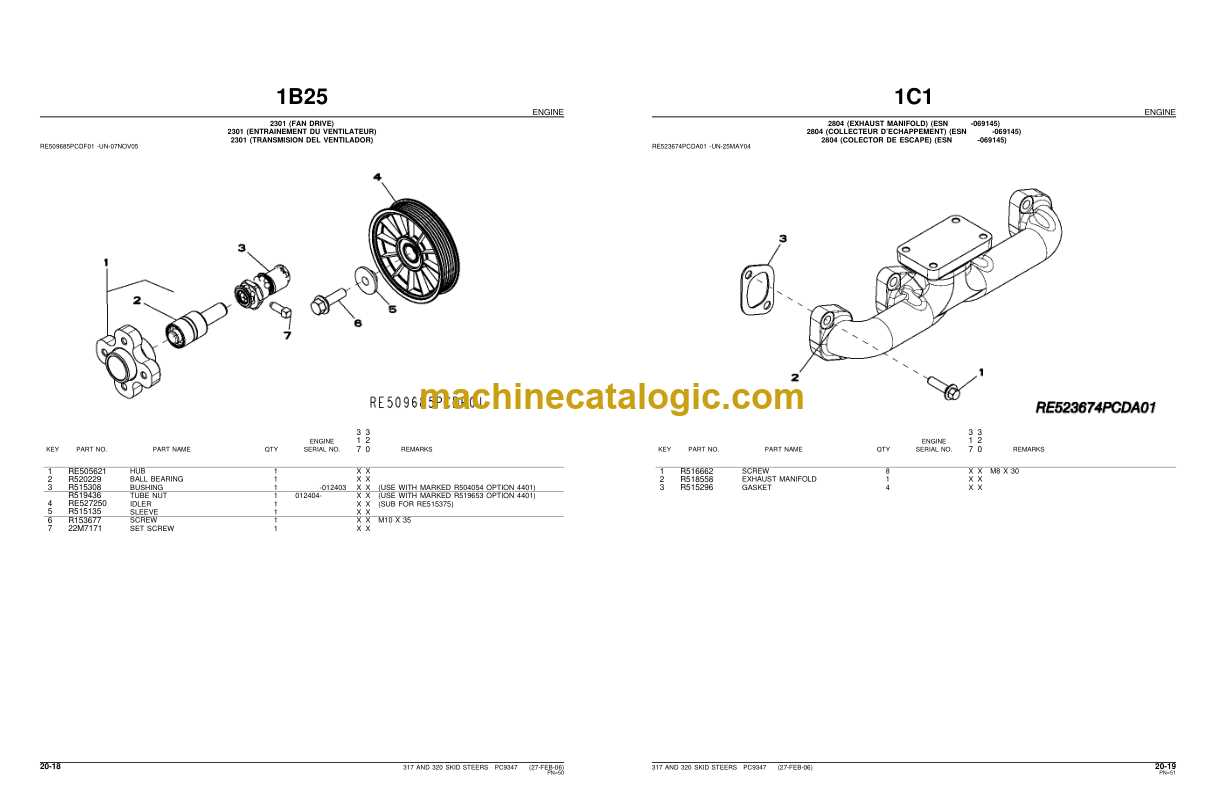

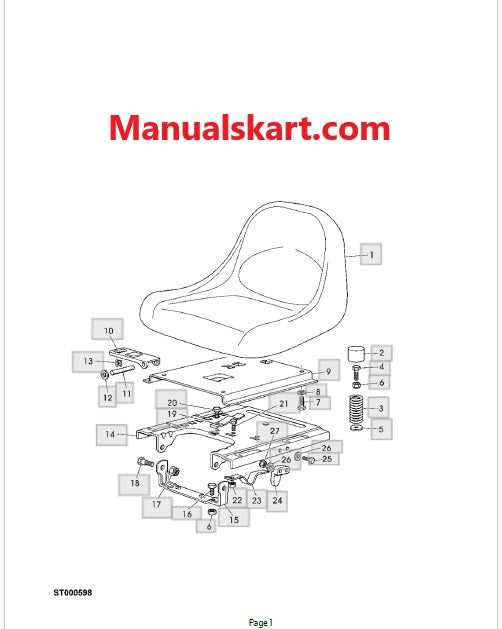

Understanding how to read a schematic or visual guide is essential for locating specific components and identifying how they fit into the overall system. A well-organized layout allows operators to quickly understand the relationships between different elements, which is crucial for performing accurate repairs and maintenance. By familiarizing yourself with the structure of these references, you can make informed decisions when handling the equipment.

Interpreting Symbols and Labels

Each component on the reference layout is typically represented by symbols or numbers, which correspond to specific parts of the machine. These symbols are standardized, making it easier to cross-reference with manuals or lists. Labels often provide additional details such as part numbers, helping you identify the correct replacement items.

Locating Key Components

To effectively read the guide, focus on understanding the main sections of the layout. The components are usually grouped by function or location, allowing you to pinpoint parts quickly. Once you know where each part is located in the schematic, it becomes much easier to troubleshoot issues or carry out replacement tasks.

Common Replacements for Tractor Components

Over time, certain components of any machine may wear out or get damaged, requiring replacement to ensure continued performance. Understanding which elements commonly need replacing can help prepare owners for maintenance tasks. Regularly replacing these components can prevent larger, more costly issues from arising and help the equipment run smoothly.

Belts and filters are among the most frequently replaced items. These parts are exposed to regular wear and tear due to their continuous use and are essential for maintaining the machine’s efficiency. Replacing them on schedule prevents breakdowns and ensures that the equipment continues to function at its peak.

Additionally, components such as spark plugs and air filters are vital for the engine’s optimal performance. When these elements degrade, the engine can struggle to operate efficiently, which may lead to reduced power or fuel efficiency. Regularly checking and replacing these parts will keep the engine running smoothly.