For any farm equipment, having a solid understanding of its attachment system is essential. The correct identification and maintenance of individual elements help ensure the machinery operates smoothly and efficiently. Knowing how each component fits together can prevent costly repairs and downtime.

In this guide, we will explore the key elements of the attachment mechanism commonly used in agricultural machinery. We will focus on how to recognize each component and provide insights into their functions. With the right information, you can effectively manage your equipment and extend its lifespan.

Proper care and knowledge of these components are vital for anyone involved in maintaining or operating heavy machinery. By understanding how these pieces work in unison, you can ensure a seamless experience on the field.

Understanding Tractor Attachment Components

To operate farm machinery effectively, it is crucial to understand the connection system that links implements to the vehicle. These attachments play a central role in performing various agricultural tasks, and having a clear grasp of how they function is essential for both maintenance and efficiency. Each element of the connection mechanism serves a specific purpose, allowing the machinery to perform a range of operations seamlessly.

Main Connecting Elements

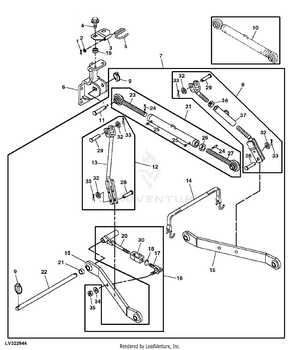

The primary elements of the attachment system consist of the links, arms, and the mounting points that secure the implements. These components work together to ensure that the attached equipment remains stable and functional during operation. Proper alignment and secure fastening are vital for preventing damage or malfunction.

Adjustments and Maintenance

Regular inspection and adjustment of these components are necessary to maintain optimal performance. Over time, wear and tear can affect the fit and function of the attachment elements, making periodic maintenance essential. Ensuring that all connections are properly lubricated and tightened will contribute to the longevity of the machinery and prevent downtime.

How to Identify Hitch Parts

Recognizing and understanding the various components of the attachment mechanism is the first step in maintaining and troubleshooting agricultural machinery. Each part plays a specific role, and knowing how to identify them will make it easier to perform necessary repairs or replacements. Proper identification ensures that you are working with the correct components, leading to efficient operation and reduced risk of malfunction.

Common Components and Their Functions

The connection system typically includes a variety of components such as the arms, brackets, and locking mechanisms. Each of these parts has a unique function. The arms connect to the vehicle’s rear, providing the necessary movement for the attached implements. Brackets serve as support points, while locking mechanisms ensure everything stays securely in place during operation.

Using Reference Materials

For accurate identification, it is essential to consult reference guides or schematics that show each component’s position and function. These resources can help distinguish between similar-looking elements, making it easier to identify issues or potential upgrades. Having a clear understanding of the system will guide you through necessary adjustments or repairs.

Maintenance Tips for Kubota Hitches

Regular maintenance of the connection system is essential to ensure the longevity and proper functioning of agricultural machinery. By following a few simple maintenance practices, you can prevent wear and tear, minimize downtime, and ensure that the machinery operates at its best. Proper care not only extends the life of the equipment but also improves its overall efficiency and performance during work.

One of the most important aspects of maintaining these systems is regular inspection. Over time, components can experience damage from constant use, so checking for signs of wear, rust, or looseness is crucial. Keeping everything clean and properly lubricated will also prevent unnecessary friction and corrosion, helping to avoid more costly repairs down the road.

Additionally, it’s essential to ensure that all components are securely fastened and correctly aligned. Loose parts can cause instability and lead to further damage to both the machinery and the implements. Tightening bolts and checking the alignment of the connecting arms and supports should be part of routine maintenance.