When using high-performance tools, understanding their internal mechanisms can significantly improve efficiency and longevity. Each tool is made up of multiple components that work together to achieve the desired outcome. Knowing the function of each piece is essential for both optimal use and proper maintenance.

Recognizing key elements that contribute to tool operation allows users to identify any potential issues before they cause more damage. Regular inspection and awareness of how different parts interact ensure a smoother workflow and prevent unnecessary wear.

Maintaining these machines requires knowledge of the vital elements that comprise them. Whether for repair or routine care, an understanding of tool components is necessary for making informed decisions and keeping the equipment in top condition.

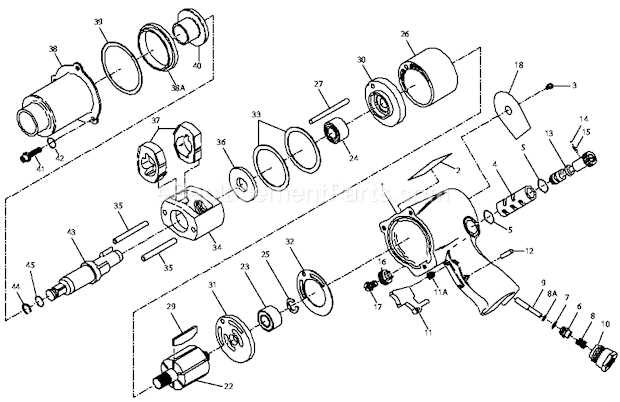

Understanding the Components of an Air Impact Wrench

The performance of any tool depends on the smooth interaction between its internal elements. Each component serves a specific purpose and contributes to the overall functionality, from generating power to transferring it effectively. By understanding the relationship between these parts, users can ensure their equipment performs at its best for longer periods.

The Core Elements of Tool Mechanics

At the heart of any power tool are the components that generate and control movement. The mechanism responsible for driving force typically consists of a motor, trigger, and rotational housing. The motor acts as the driving force, converting energy into motion, while the trigger provides precise control over power delivery. The housing directs this motion to the tool’s working end.

How Internal Parts Work Together

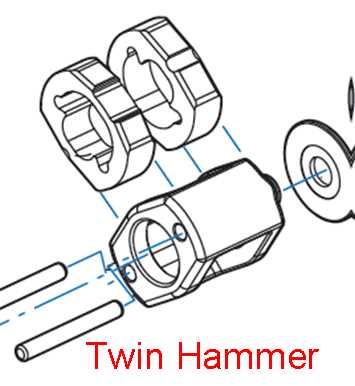

Each component is designed to interact with others in a seamless manner. For instance, the gearing system plays a key role in adjusting the rotational speed and torque. Efficient coordination between the gears and the motor is crucial for achieving consistent performance. Additionally, elements such as seals and lubricants ensure that internal friction is minimized, reducing wear over time.

Key Parts That Drive Performance in Wrenches

The performance of any power tool is directly influenced by the efficiency of its critical components. These essential elements work together to generate and control force, ensuring the tool delivers the required output effectively. Understanding which parts are responsible for key functions helps users maintain optimal performance and prevent issues that can arise from wear and tear.

Among the most vital components are the motor, which generates the driving force, and the mechanism that transmits that force to the working end. Torque regulation and speed control systems play crucial roles in ensuring the tool can handle various tasks efficiently. The trigger and housing elements are also key to delivering precise control and comfort to the user during operation.

How to Maintain Your Air Impact Wrench

Proper maintenance is essential for extending the life of any tool and ensuring it continues to perform at its peak. Regular upkeep prevents unnecessary damage and helps avoid costly repairs. By following a few simple steps, users can ensure their equipment remains in optimal working condition for years.

Start by regularly checking the key internal components, such as the motor and gears, for any signs of wear or debris buildup. Lubrication is crucial in keeping moving parts functioning smoothly, reducing friction, and preventing damage. Additionally, it’s important to inspect seals and housing to avoid air leaks and ensure proper functionality during use.

Regularly cleaning the exterior and checking for any loose screws or worn-out parts also contribute to maintaining performance. By storing the tool properly when not in use and keeping it free from moisture and dust, users can ensure longevity and efficiency.