Understanding the internal structure of complex systems is essential for proper maintenance and troubleshooting. By examining the layout and function of various elements, users can ensure longevity and optimal performance. This detailed overview highlights the critical aspects necessary for efficient operation and repair.

Identification and understanding of each individual component allows for more precise diagnostic procedures and preventive care. When familiar with how each part interacts within the system, the chances of avoiding future malfunctions are greatly improved.

Knowing the configuration of essential components can save time and reduce costs, whether for repairs, replacements, or routine check-ups. With the right tools and knowledge, maintaining a smooth operation becomes a much simpler task.

Understanding Key System Components

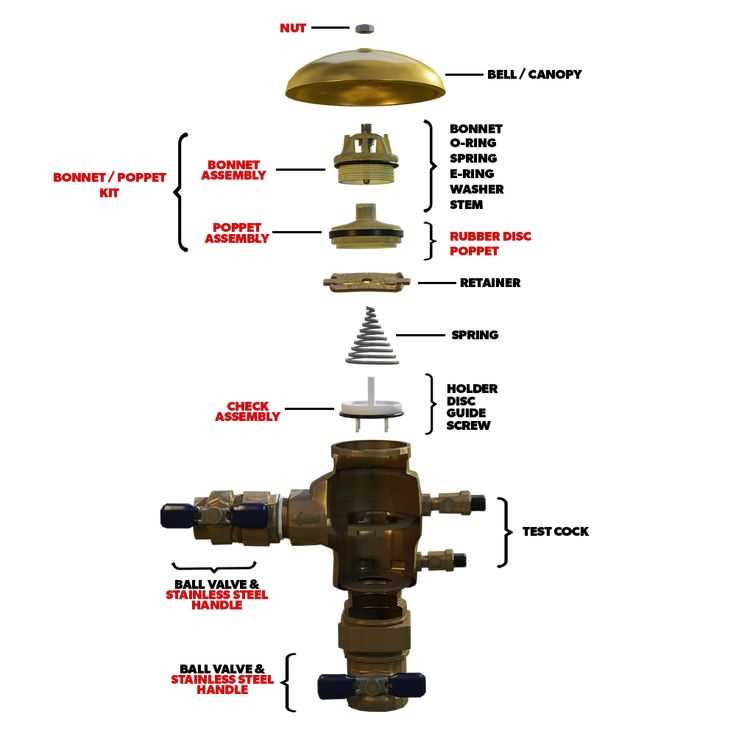

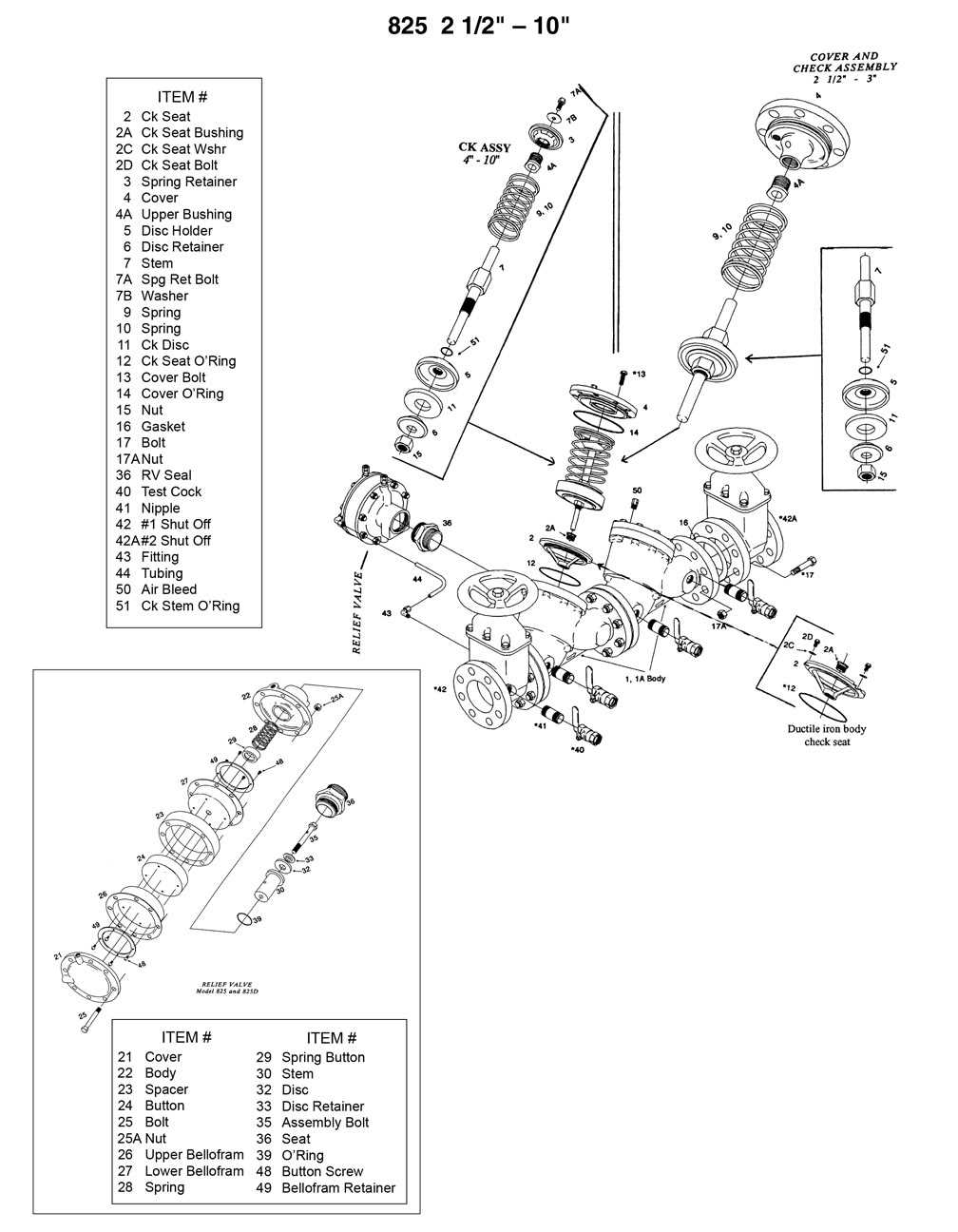

Familiarity with the various elements within a mechanical system is crucial for proper operation and maintenance. Each individual component serves a unique function, contributing to the overall efficiency and reliability of the equipment. A thorough understanding of these parts ensures that they work together seamlessly, minimizing downtime and preventing unnecessary repairs.

The primary components in this system are designed to manage fluid flow, pressure regulation, and operational control. These elements often include valves, seals, and regulators, all of which play a vital role in maintaining consistent performance and safeguarding against potential issues. Recognizing how each part interacts with the others allows for more accurate troubleshooting and smoother operations.

Regular inspection and a deeper knowledge of these crucial components enable early identification of wear or malfunction. This proactive approach helps extend the lifespan of the system and reduces the need for costly repairs or replacements in the long run.

How the System Operates

The efficient functioning of this system relies on the coordinated actions of several integral components that manage fluid flow and pressure regulation. These parts work together to ensure smooth operation, maintaining consistent pressure and preventing contamination. By controlling the flow rate and minimizing disruptions, the system ensures reliable and safe performance in various applications.

The key mechanism behind its operation involves the regulation of water or other fluids through strategically placed valves and regulators. These components allow for precise control, automatically adjusting to maintain the desired pressure levels. As the system processes the fluid, it effectively separates debris, ensuring only clean, usable material continues through the cycle.

This dynamic process allows the system to respond to changes in pressure and environmental conditions. Whether under normal operation or during adjustments, it adapts efficiently, minimizing wear and enhancing longevity. The streamlined design optimizes performance while ensuring ease of maintenance and quick identification of any issues that might arise.

Common Maintenance for the System

Routine care and upkeep are essential to maintain the efficiency and longevity of any mechanical system. Regular inspection and maintenance help prevent breakdowns and ensure all components function at optimal levels. Proper care can significantly reduce the likelihood of costly repairs and extend the lifespan of the equipment.

Inspection and Cleaning

Regular inspection is critical to identify any wear, leaks, or malfunctions early on. Cleaning filters, valves, and other key components helps maintain smooth operation, preventing blockages and reducing strain on the system. Keeping these elements free from debris ensures they perform efficiently, especially in environments where contaminants may be present.

Lubrication and Seal Replacement

Lubricating moving parts helps minimize friction and wear, which can lead to system failures over time. Replacing seals when necessary is also crucial to prevent leaks and maintain pressure. These small maintenance tasks can prevent more significant problems, saving both time and resources in the long run.