Understanding the intricate elements of your farming equipment is crucial for maintaining its efficiency and ensuring long-term performance. Whether you are dealing with mowing machinery or other agricultural tools, knowing how the various components work together can significantly improve your maintenance routine. A clear understanding of these parts helps in identifying potential issues and optimizing functionality.

In this guide, we will explore the primary components of the machine, highlighting their roles and interconnections. With a focus on proper care and troubleshooting, this section aims to provide you with the knowledge needed to keep your equipment running smoothly. Regular upkeep is essential, and understanding how each part contributes to the overall operation will make it easier to detect any signs of wear and take corrective actions early.

Overview of Hesston 1120 Haybine Parts

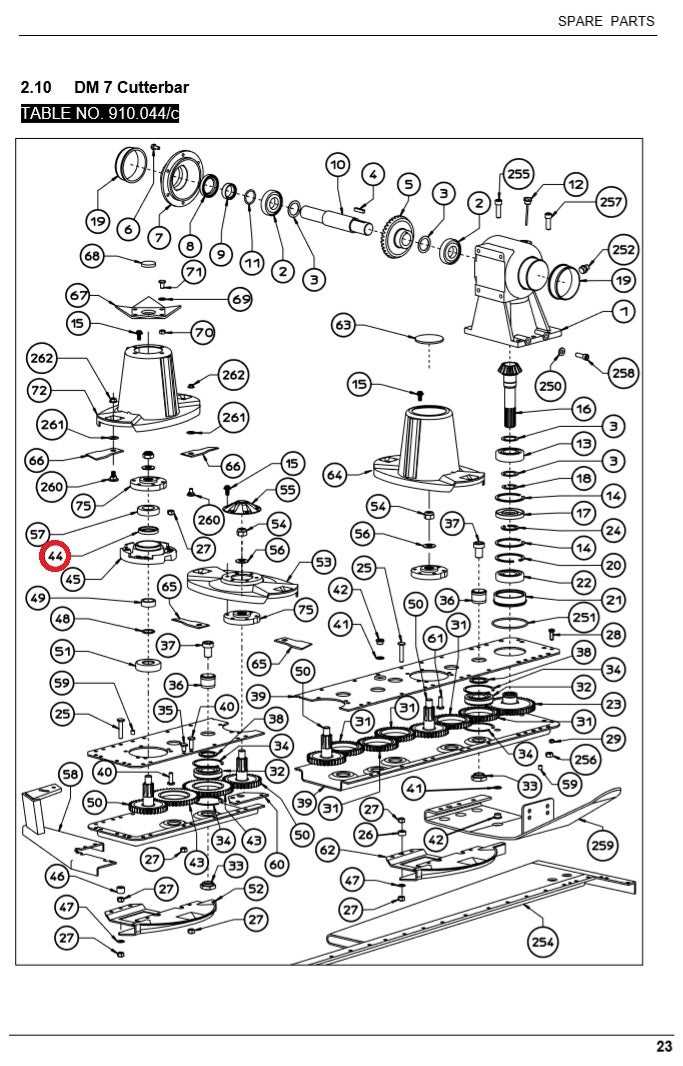

Farming equipment consists of numerous interconnected elements, each playing a vital role in ensuring smooth operation and optimal performance. Understanding these components allows for more effective maintenance and timely repairs. In this section, we will focus on the key elements that make up the machinery, describing their functions and importance in the overall system.

The various components of the machine work together to accomplish tasks efficiently, from cutting to gathering. Each part is designed to meet specific operational needs, contributing to the overall productivity of the equipment. Regular inspection of these parts is necessary to avoid malfunctions and ensure smooth performance during heavy usage.

From the power transmission system to the cutting mechanism, the structure is built to withstand demanding field conditions. The connection between each piece must be understood to make informed decisions regarding upkeep and troubleshooting. Ensuring that all components are functioning properly is essential to maintaining the longevity and efficiency of your agricultural equipment.

Understanding the Key Components and Functions

Every piece of agricultural machinery is made up of a variety of essential elements that work together to achieve efficient performance. These key components are designed to handle different tasks and contribute to the overall success of the equipment. Understanding how each element functions and interacts with the others is critical for effective operation and long-term reliability.

The drivetrain, which includes the engine, gears, and belts, is responsible for powering the system, ensuring that energy is transferred efficiently to various moving parts. The cutting mechanism, consisting of blades and related components, is the core function of the machinery, enabling it to perform the intended task with precision. Additionally, the framework and support structure provide the stability needed for the machinery to handle tough conditions in the field.

Regular attention to each component’s condition is necessary for maintaining optimal performance. Small adjustments and early detection of wear can prevent major breakdowns and costly repairs. By understanding the function of each part, operators can better diagnose issues and make informed decisions about repairs and maintenance schedules.

How to Maintain Your Hesston 1120 Haybine

Proper maintenance is essential to keeping agricultural machinery running efficiently and extending its lifespan. Regular care and timely servicing can prevent breakdowns and costly repairs. In this section, we’ll explore key maintenance practices that will help ensure your equipment operates at its best, season after season.

Routine Inspections and Cleaning

Start by conducting regular visual inspections to check for any signs of wear or damage. Look for loose parts, frayed belts, or damaged components that could affect performance. Cleaning the equipment after each use is crucial to prevent buildup of dirt, grass, or debris that could interfere with the machinery’s functions. Use compressed air or brushes to clear the cutting area and the drivetrain components.

Lubrication and Adjustments

Lubricating moving parts regularly reduces friction, which helps to prevent premature wear and tear. Be sure to follow the manufacturer’s recommended lubrication schedule for bearings, gears, and any other components that require attention. Additionally, check for any necessary adjustments, such as tensioning belts or aligning parts, to ensure smooth operation and prevent uneven wear.