Efficient maintenance and repair of refrigeration systems rely on a clear understanding of their internal structure. Each unit consists of multiple elements that work together to ensure optimal performance. Knowing how these components are arranged and how they function is crucial for proper troubleshooting and repairs. This guide provides insights into the key elements that make up these cooling systems and how they can be identified for easy maintenance.

Key Elements in Cooling Units

Cooling systems are made up of several integral parts, each serving a specific purpose. Below are the most important components:

- Compressor: The heart of the system, responsible for circulating refrigerant through the system.

- Evaporator: Helps to absorb heat from the air inside the unit and allows the refrigerant to evaporate and cool the surroundings.

- Condenser: Releases the heat absorbed by the refrigerant, ensuring that the system remains efficient.

- Expansion Valve: Regulates the flow of refrigerant into the evaporator, controlling pressure and temperature.

How to Identify and Replace Faulty Components

Properly identifying which element is malfunctioning can save time and effort in the repair process. Some common signs of faulty components include:

- No cooling: The system may be low on refrigerant, or the compressor might be malfunctioning.

- Overheating: If the condenser or expansion valve isn’t working, it can cause overheating and system failure.

- Strange noises: Unusual sounds may indicate a problem with the compressor or internal parts like the fan or motor.

Replacement and Compatibility Considerations

When replacing any part, ensure that it matches the specific requirements of the system. Using incompatible components can lead to further damage or inefficiency. Always consult the manufacturer’s guidelines to confirm that the replacement parts will fit and function properly.

Understanding System Components and Maintenance

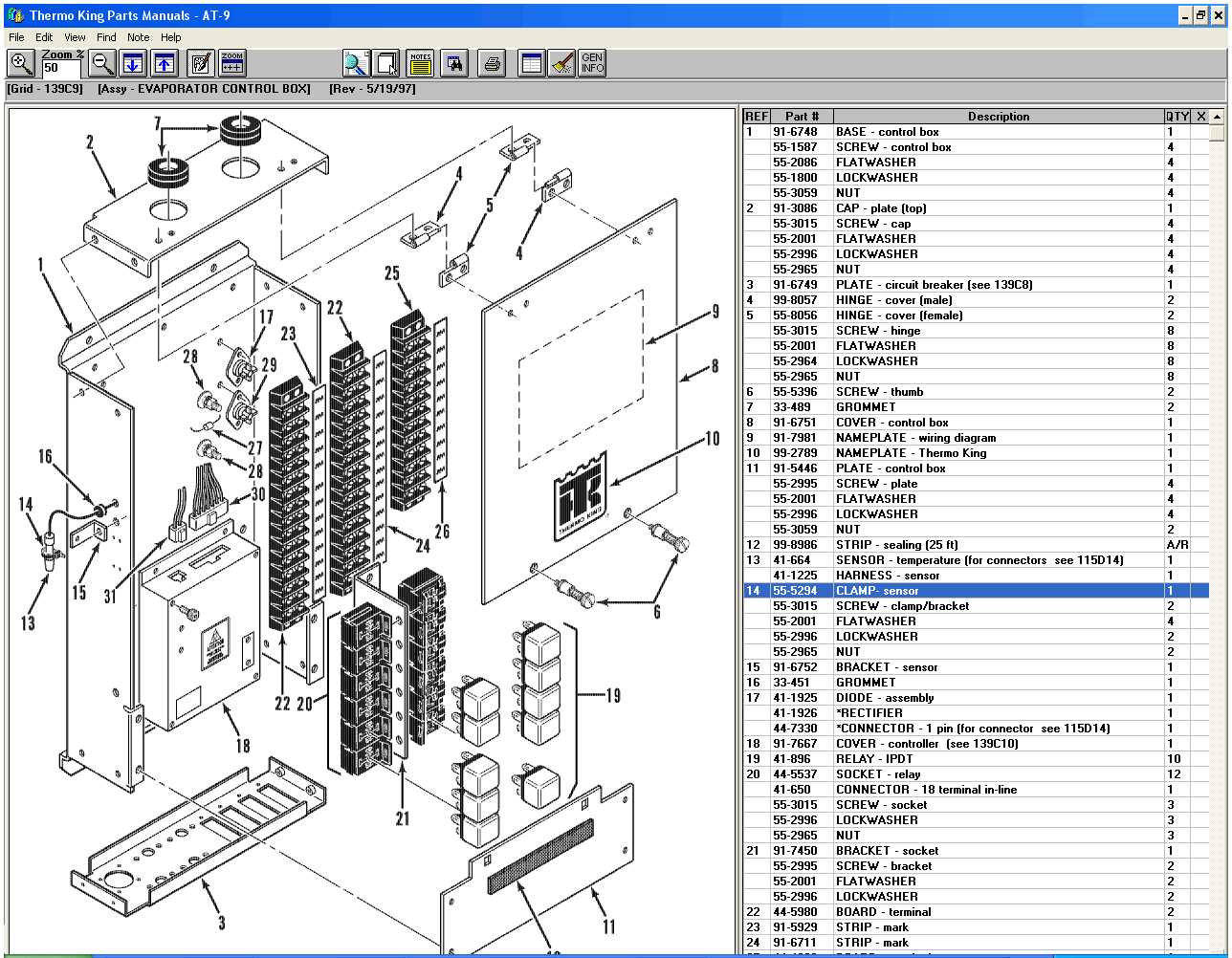

Efficient operation of refrigeration systems depends on a thorough understanding of their internal structure and how each element interacts with others. Knowing the layout of these components is essential for effective troubleshooting, repair, and routine maintenance. This section provides insights into recognizing the main system elements, identifying potential issues, and selecting the right components for repair or replacement.

To accurately interpret the system structure, it’s important to familiarize yourself with the primary components. These are typically shown in detailed guides, which illustrate where each part is located and how they connect to ensure the unit functions optimally. A clear understanding of these components helps in diagnosing faults and aids in making repairs efficiently.

Key elements include compressors, evaporators, condensers, and control units. Each plays a critical role in maintaining temperature regulation, airflow, and energy efficiency. When one of these components malfunctions, it can disrupt the entire system, leading to cooling issues or potential damage to other parts.

Regular upkeep is necessary to prolong the lifespan of the system. This includes cleaning, lubricating moving parts, and replacing any worn components. Keeping track of the system’s condition through regular inspections can prevent major issues from developing and save on costly repairs.

When replacing damaged or worn-out components, ensure they match the specifications of the original system. Compatibility is crucial, as incorrect replacements can cause more harm than good, leading to system inefficiency or failure. Always consult with trusted sources to verify the parts’ compatibility before making replacements.