Maintaining and troubleshooting any machine requires a clear understanding of its internal structure. Knowing how each element functions together ensures smooth operation and easy identification of any issues that may arise. Whether you’re looking to replace a worn-out part or perform routine maintenance, having a reliable reference is crucial.

In this section, we will explore the essential components that make up the system. From the power source to the smaller connections, every piece plays an important role in ensuring everything works as it should. By understanding the layout and functionality of each section, you can approach repairs and maintenance with confidence.

Identifying specific parts and understanding their relationship within the equipment can save time and money, eliminating the need for unnecessary replacements. A well-organized breakdown provides the insight needed to resolve common malfunctions.

Whether you’re an experienced technician or a beginner, having a comprehensive overview of the machinery’s parts helps streamline the troubleshooting process. With the right knowledge, even complex issues can be addressed efficiently.

Understanding the Simpson 3400 Parts Diagram

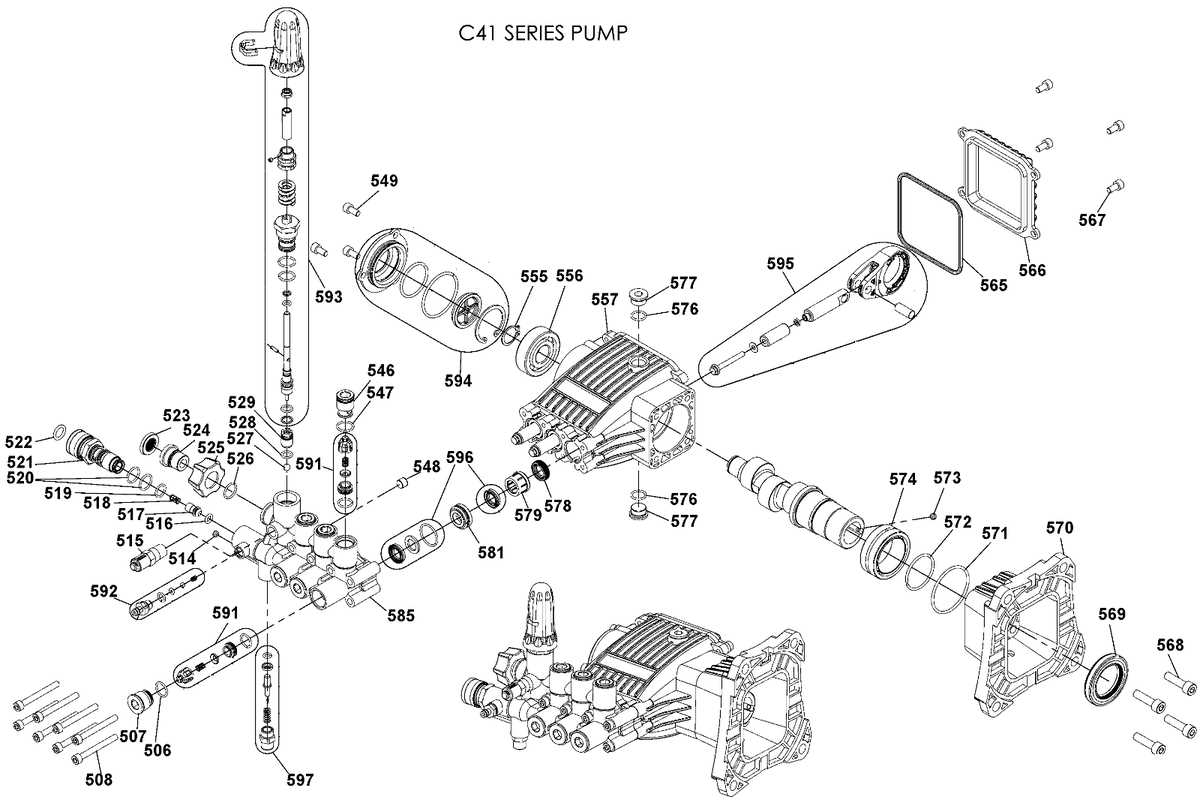

When dealing with complex machines, having a detailed visual reference is invaluable for identifying each component and its function. A comprehensive schematic helps break down the different sections of the equipment, ensuring a clearer understanding of how the system operates. By following a structured map, users can efficiently locate, repair, or replace any malfunctioning elements.

This section focuses on explaining the layout of critical components and how they interact within the unit. Understanding the positioning and relationships between parts is essential for troubleshooting and maintenance. Whether you’re inspecting individual sections or diagnosing issues, recognizing how each piece fits into the larger whole simplifies the process.

Familiarity with the design also helps prevent errors during repairs. Knowing which elements require attention and how to access them can save both time and effort. With a visual guide, even those new to the equipment can approach repairs methodically and with confidence.

Identifying Key Components of the Washer

Understanding the primary elements of any mechanical device is crucial for efficient use and maintenance. Each component plays a specific role in ensuring the overall functionality of the system. By identifying these key parts, users can troubleshoot issues more effectively and perform necessary repairs with ease.

In this section, we will focus on the main components that contribute to the operation of the equipment. These include the motor, the pump, hoses, and various connectors. Each part has its own function, and when one begins to malfunction, the entire system can be impacted.

Knowing how to recognize and assess each element allows for quicker detection of problems and ensures smoother performance. Regularly inspecting these components can prevent larger, more costly issues from arising, making routine maintenance a vital part of keeping everything running optimally.

Common Repair Solutions with Parts Diagram

Understanding how to fix common issues in mechanical devices is essential for efficient repairs and minimizing downtime. Using a visual reference of the components, it becomes easier to diagnose problems, identify malfunctioning parts, and apply effective solutions. This section highlights some of the most frequent issues users may face and provides practical repair steps.

Here are a few common problems and their solutions:

- Loss of Power: If the machine suddenly stops working, it could be due to a faulty connection or a damaged motor. Ensure all wires are intact and check for any loose components.

- Water Flow Issues: If the water flow is inconsistent or stops completely, inspect the hoses and connections for blockages. Cleaning or replacing filters can help restore normal function.

- Leaks: Leaks often occur around connectors or seals. Tightening connections or replacing damaged seals usually resolves this issue.

For each of these problems, referring to a schematic makes it easier to locate and address the specific part that requires attention. By following a clear guide, users can quickly assess the situation and determine if replacement or simple maintenance will resolve the issue.

Remember, knowing the layout of the system allows you to handle repairs without unnecessary disassembly, saving time and effort in the process.