When maintaining any mechanical or electrical system, it is crucial to have a clear understanding of its internal elements and their functions. Proper knowledge of each component allows for effective troubleshooting, repair, and overall system longevity. This section aims to provide an insightful breakdown of a specific system, emphasizing how to interpret and work with its individual elements.

By learning the arrangement and purpose of each key part, you can ensure that your system operates at peak performance. This guide will offer a detailed approach to understanding how these parts interact, helping you identify potential issues and take necessary actions when maintenance is needed.

Whether you are a professional technician or a DIY enthusiast, mastering the structure and components will significantly improve your ability to maintain and repair the system efficiently. Understanding the function of each part will empower you to make informed decisions and carry out necessary procedures with confidence.

Understanding the Key Components

Every system is made up of interconnected elements that perform specific tasks. Recognizing how each of these components functions and contributes to the overall operation is essential for effective maintenance and troubleshooting. This section breaks down the critical components of the system, highlighting their roles and interdependencies.

The key to successful maintenance lies in understanding the individual functions of each part. Below is a list of the most important elements and their contributions:

- Motor Assembly: The heart of the system, driving the entire operation. Its performance directly affects the overall efficiency.

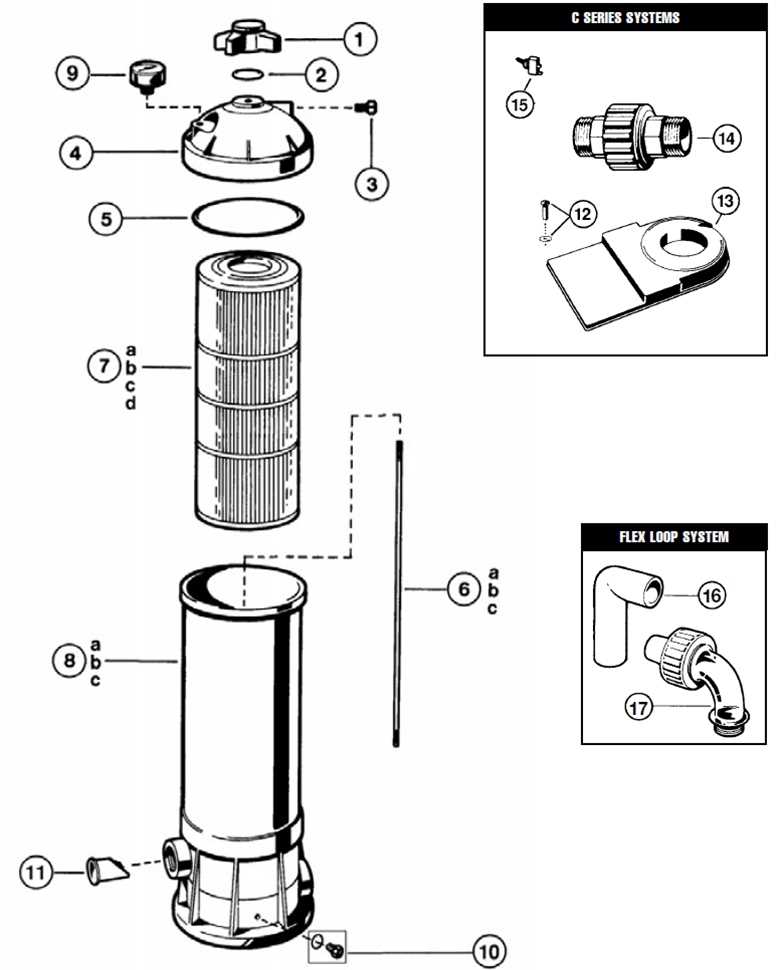

- Filter Housing: Protects and encases the filtration elements, ensuring that debris and contaminants are properly processed.

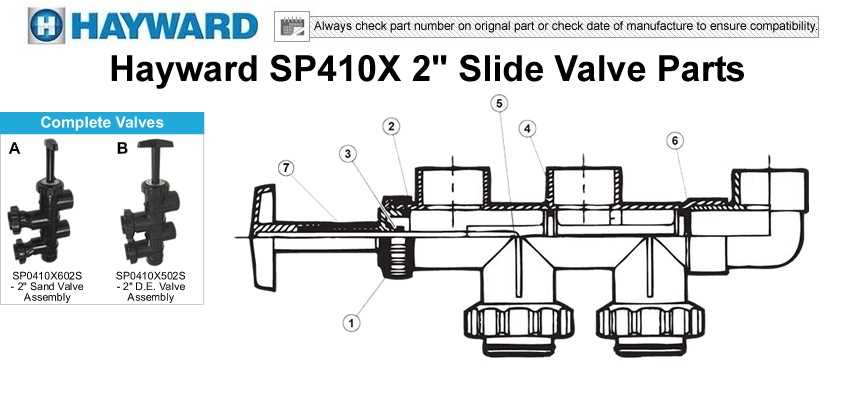

- Valves: Control the flow of fluids through the system, ensuring the proper distribution of resources at the right time.

- Gaskets and Seals: These prevent leakage, maintaining the integrity of the system by ensuring no fluid escapes where it shouldn’t.

- Control Panel: The interface that allows users to manage and monitor system performance, adjusting settings as needed.

Each of these elements plays a vital role, and understanding their individual functions ensures that the system operates smoothly. With this knowledge, you can identify issues, perform repairs, and optimize performance effectively.

Key Parts and Their Functions

Understanding the essential elements within any system is crucial for its smooth operation. Each component serves a distinct purpose that contributes to the overall functionality. This section highlights the most important parts and explains their individual roles in ensuring optimal performance.

Among the most vital components are:

- Motor: This is the primary driving force behind the system. It is responsible for generating the power needed to run the entire mechanism.

- Filter Element: This component traps dirt, debris, and other unwanted particles, ensuring that the system operates efficiently and free from blockages.

- Flow Valve: This regulates the movement of fluids, directing them through the necessary channels to maintain the desired performance.

- Gaskets and Seals: These ensure that all connections are secure and leak-proof, preventing any loss of fluid or pressure that could affect system efficiency.

- Control Mechanism: The interface that allows users to adjust and monitor the system, ensuring it operates within optimal parameters.

Each of these elements plays a crucial role in maintaining the performance and longevity of the entire system. Proper care and understanding of these components will enable more effective maintenance and problem-solving when necessary.

How to Read the System Schematic

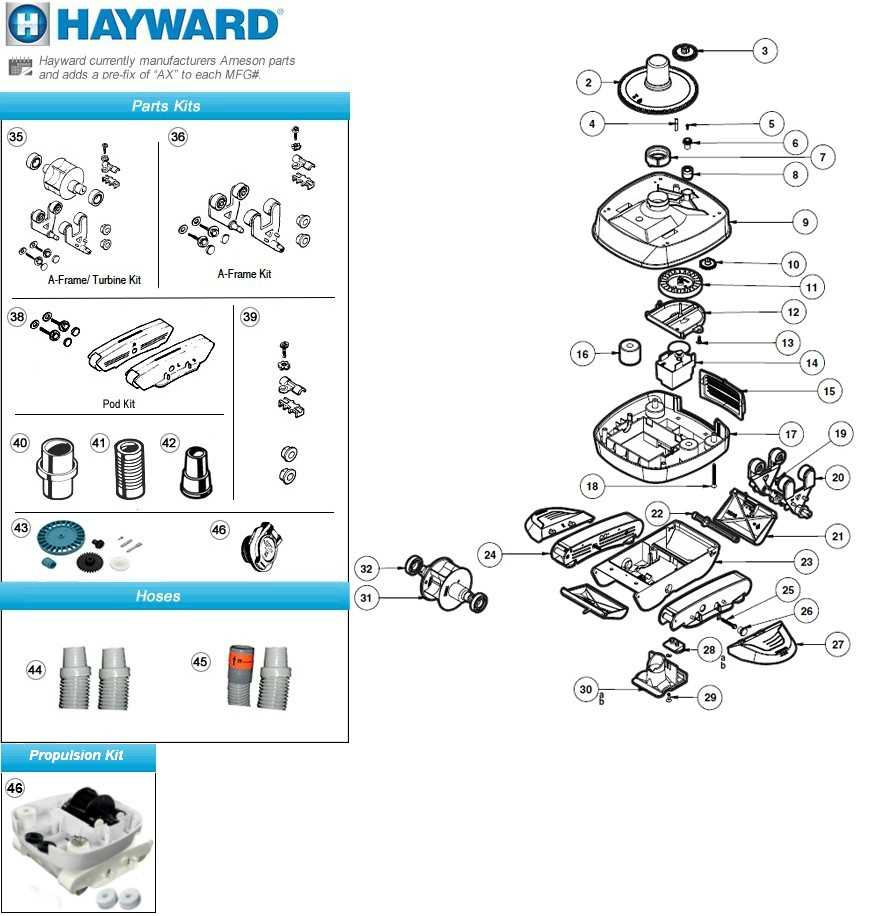

Understanding a system schematic is crucial for effective maintenance and troubleshooting. A schematic provides a visual representation of the components and their connections, helping you interpret how each part interacts with others. In this section, we will guide you on how to read and interpret these diagrams to make maintenance easier and more accurate.

Start by identifying the major components within the schematic. Typically, these are represented by symbols that correspond to their real-world counterparts. Here’s how to approach reading the schematic:

- Component Symbols: Each part will have a specific symbol, which is essential to identify. Familiarize yourself with common symbols to understand what each one represents.

- Flow Direction: Arrows are usually used to indicate the direction in which fluids or electricity flow, helping you understand the system’s operation.

- Connections: Lines between components show how they are interconnected. Pay attention to how different parts link to each other to grasp the entire system’s setup.

- Color Coding: Some schematics may use colors to differentiate between various elements, such as power sources or types of connections. This can help you quickly identify key parts.

By following these steps, you can quickly become proficient in reading and understanding system schematics. This knowledge enables you to troubleshoot issues, replace damaged components, and ensure your system continues to function at its best.

Step-by-Step Guide to Interpretation

Interpreting a technical schematic requires a methodical approach to ensure accurate understanding. By following a clear, step-by-step process, you can easily navigate through complex diagrams and identify key components, connections, and their functions. This guide provides a straightforward method for interpreting the layout and relationships of each element.

Step 1: Familiarize Yourself with the Symbols

The first step is to understand the symbols used in the schematic. Each component is represented by a specific shape or icon, which corresponds to a real-world part. Start by identifying the most common symbols, such as motors, valves, and switches, and refer to a legend or key if available for clarification.

Step 2: Trace Connections and Flow

Once you are familiar with the symbols, focus on tracing the connections between components. Follow the lines or arrows to understand how the system flows. These connections reveal how the components interact and are crucial for identifying potential issues with the setup.

By following this step-by-step method, you can gain a clearer understanding of the schematic and effectively troubleshoot or maintain the system. This approach helps break down complex layouts into manageable parts, making it easier to interpret the entire diagram.

Maintaining Your System

Regular maintenance is essential to ensure that any system continues to perform at its best. Proper care not only prolongs the life of the equipment but also helps prevent unexpected failures. In this section, we will discuss key steps to maintain your system effectively and keep it running smoothly for years.

The foundation of good maintenance includes routine inspections, cleaning, and part replacements as needed. Start by regularly checking for any signs of wear or damage to the main components. Ensuring that all connections are tight and free from leaks can prevent many common issues. Also, cleaning filters and valves frequently is important to maintain optimal performance and avoid blockages.

Another important aspect of maintenance is lubricating moving parts to reduce friction and prevent unnecessary wear. Regularly testing the system’s functionality will help you identify any minor issues before they escalate into larger, more costly problems.

By following these maintenance guidelines, you can ensure that your system operates efficiently, minimizes downtime, and extends its service life.