When it comes to maintaining outdoor power tools, having a clear understanding of their internal structure is essential. With the right knowledge, you can easily identify issues, perform repairs, and ensure your equipment continues to perform at its best. One of the most important aspects of maintenance is knowing how each component fits together and functions.

Understanding the inner workings of your machine allows you to quickly troubleshoot common issues. By using a detailed reference, you can pinpoint malfunctioning parts and replace them with precision. This not only saves time but also prevents unnecessary wear on your equipment.

In this guide, we will explore the various elements that make up the tool’s structure and show you how to efficiently use a reference to navigate through repairs and upkeep. With this knowledge, performing maintenance will become a more straightforward and less time-consuming task.

Understanding the Stihl BR 700 Parts

Knowing the components of your outdoor equipment is crucial for proper maintenance and effective troubleshooting. Understanding how each piece works in harmony allows for more efficient repairs and a longer lifespan for your machine. A well-maintained blower relies on the proper function of its various internal mechanisms, from the engine to the air intake system.

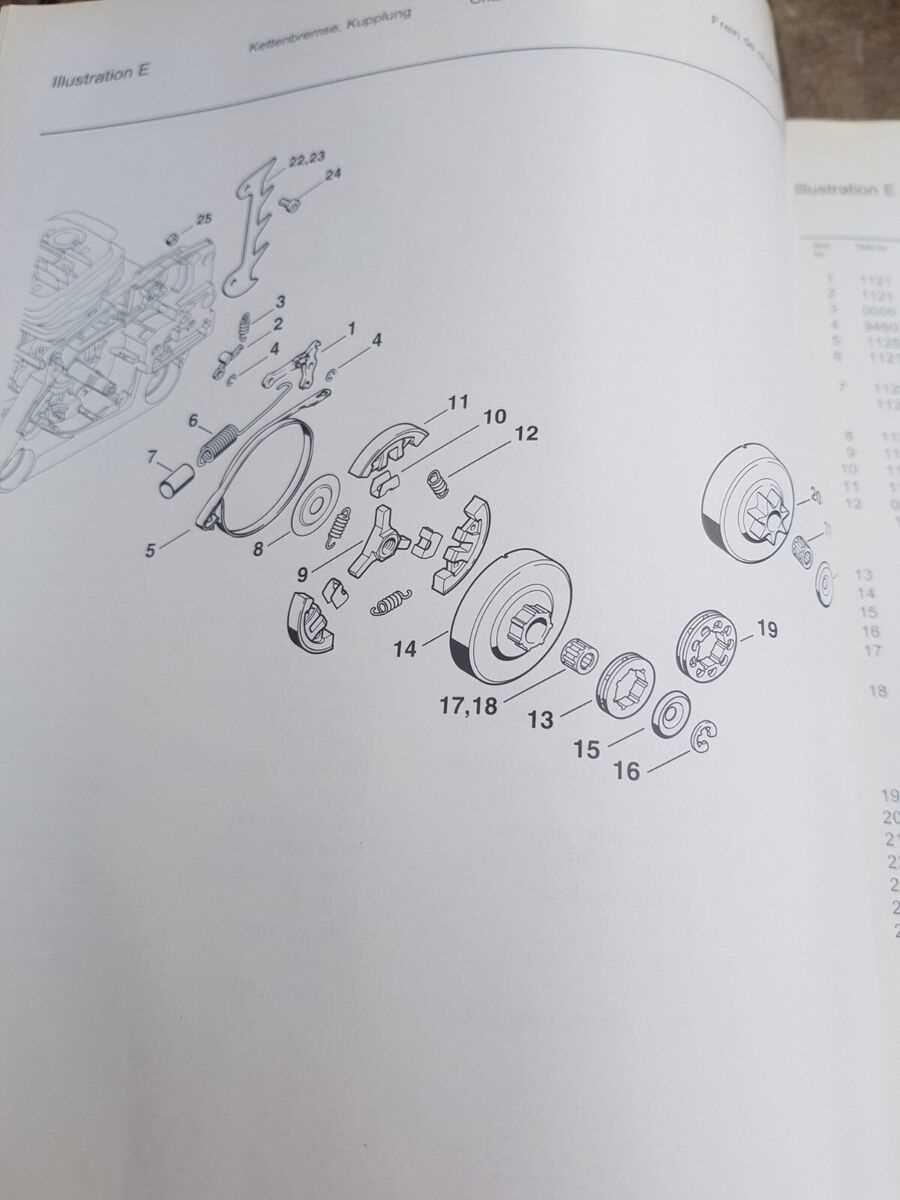

Main Engine Components

The engine is at the core of the machine’s functionality. It is responsible for providing the power necessary to operate the blower. Key components of the engine include the carburetor, spark plug, and the air filter, all of which must be checked regularly to ensure the machine operates smoothly. Each part plays a vital role in maintaining the right fuel and air mixture for optimal performance.

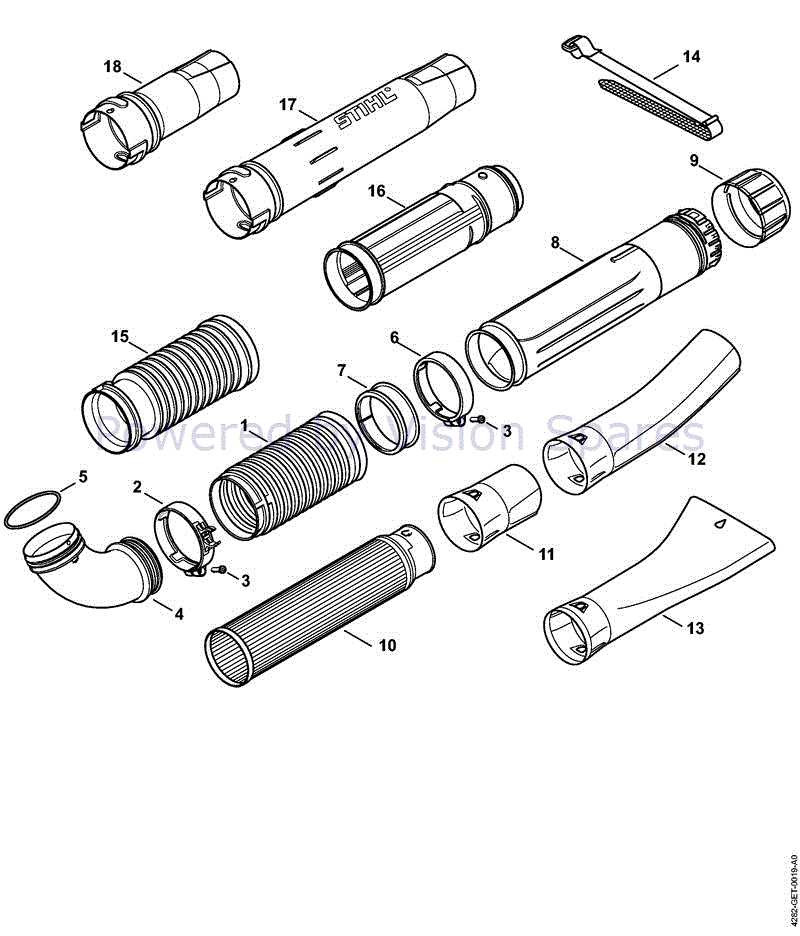

Airing System and Housing

The air circulation system plays an important role in directing airflow efficiently. This system includes parts such as the fan, impeller, and exhaust, which work together to create powerful airflow. Regularly inspecting these components helps prevent debris from building up, which could cause blockages or reduce efficiency.

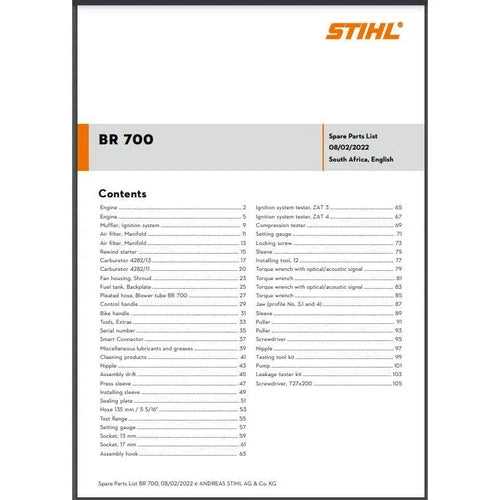

How to Use the Parts Diagram

When maintaining or repairing your outdoor tool, a clear reference guide is essential for understanding the layout and function of each component. A well-organized visual reference can simplify the process of locating and identifying individual elements, making repairs faster and more accurate. Knowing how to interpret this guide will help you avoid errors during the disassembly and reassembly process.

Identifying Key Components

The reference guide typically shows a breakdown of all the main elements in the tool, allowing you to easily locate the part you’re looking for. Start by identifying the most prominent sections such as the engine, housing, and air circulation system. This will help you quickly navigate the guide, whether you’re troubleshooting an issue or replacing a damaged piece.

Utilizing the Part Numbers

Part numbers are crucial for ordering replacements. Each component is usually accompanied by a unique number that identifies it precisely. Using the diagram, locate the part in question and note its number to ensure you get the correct replacement. This eliminates confusion and guarantees a more efficient repair process.

Common Repairs with Stihl BR 700 Parts

Outdoor power tools often require regular maintenance and occasional repairs to keep them functioning properly. Understanding the most common issues that arise and how to address them is key to prolonging the life of your equipment. Common repairs generally involve issues with the engine, air circulation system, or other essential components that ensure optimal performance.

Engine Troubleshooting and Repairs

The engine is one of the most frequently repaired areas of outdoor equipment. Over time, components such as the spark plug, carburetor, or fuel lines may become clogged or damaged, affecting the overall function. Regularly checking these parts for wear and replacing them when necessary can prevent more significant problems and keep the tool running smoothly.

Airflow System Maintenance

Another common repair involves the airflow system. Over time, debris can accumulate in the fan or air intake, restricting airflow and reducing efficiency. Ensuring that these parts are clean and free of blockages is essential for maintaining optimal performance. Replacing worn-out parts like the fan or impeller can restore the tool’s power and effectiveness.