When working with complex machinery, understanding the internal elements and their connections is essential for maintenance and troubleshooting. Each system consists of numerous components that interact to ensure optimal performance. Knowing how these parts fit together can save time and effort during repairs and prevent unexpected breakdowns.

In this guide, we will explore the layout and structure of vital system components. By breaking down each part’s function and placement, you will gain valuable insight into how everything works in unison. This knowledge can help identify issues quickly and accurately, improving overall efficiency and longevity.

Recognizing key features and understanding their role within the larger system is crucial. Whether you are a technician or an operator, familiarity with these intricate details will empower you to make informed decisions when handling mechanical systems. Stay proactive and ensure your equipment runs smoothly with a deeper understanding of its inner workings.

Understanding Key System Components

The performance of any mechanical system relies heavily on the proper functioning of its various elements. A thorough understanding of how these components are arranged and interact with each other is crucial for both maintenance and troubleshooting. Identifying the key pieces of the system and knowing their individual roles can make a significant difference in system longevity and efficiency.

Essential Elements and Their Roles

Each component within a complex system serves a specific function that contributes to the overall operation. From energy conversion to control mechanisms, every part has a purpose. Familiarizing yourself with these individual parts and their relationship with one another will enable you to recognize early signs of malfunction and take corrective measures swiftly.

How Components Work Together

Understanding the interaction between various system elements is equally important. When properly synchronized, these parts work in harmony to ensure smooth operation. By studying their layout and connections, you gain insight into how an issue in one area might affect the entire system, allowing for more effective diagnostics and faster resolutions.

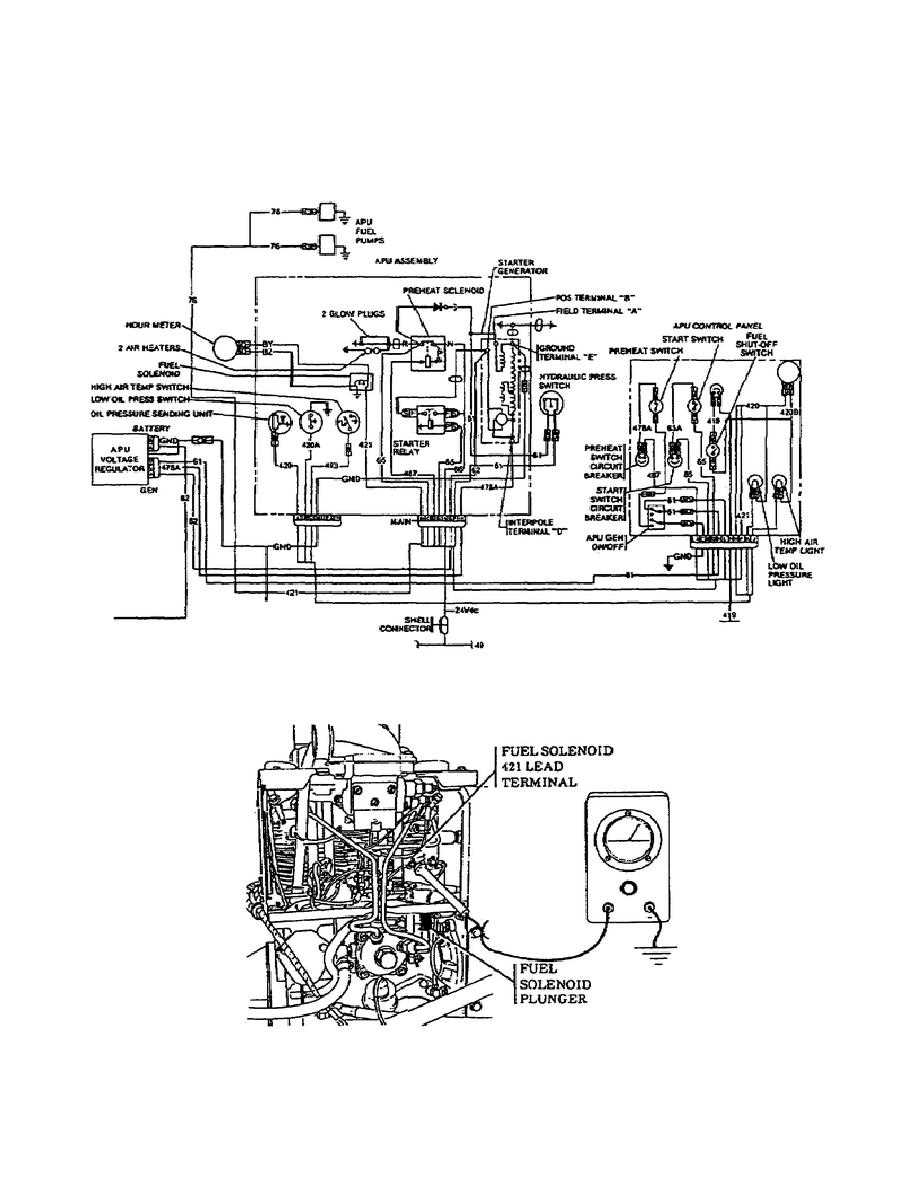

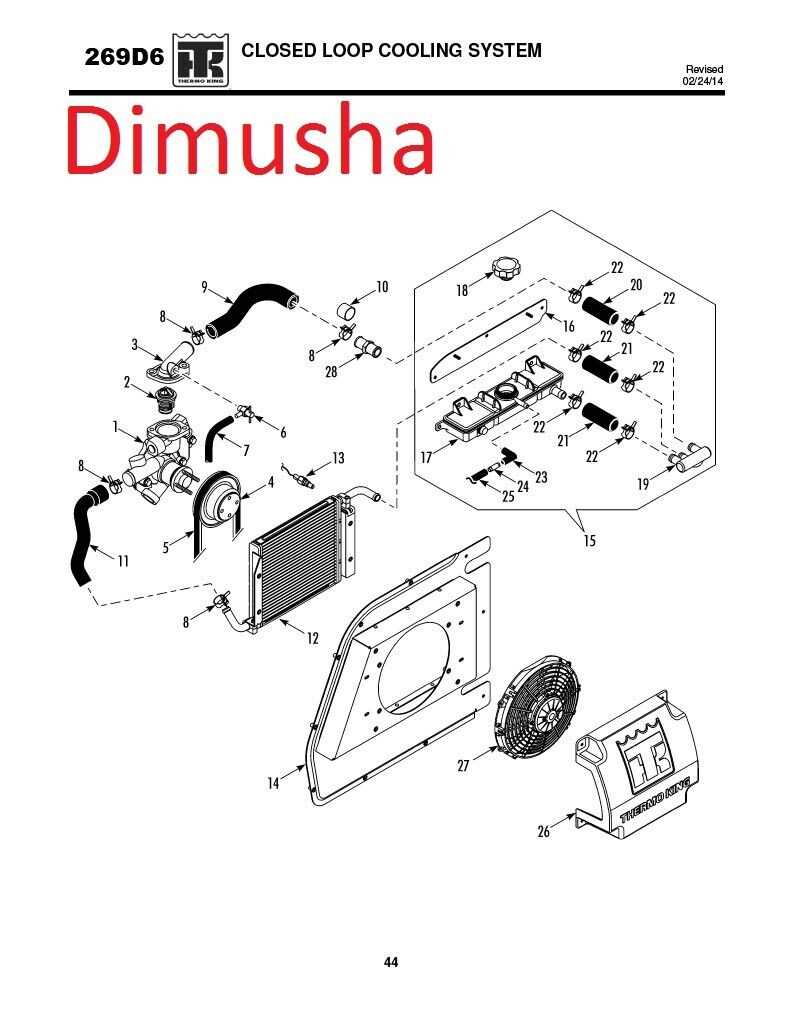

How to Read System Component Layouts

Understanding a layout of system components is crucial for effectively maintaining and troubleshooting machinery. These layouts provide a clear representation of how different elements are arranged and connected. Familiarity with how to interpret these visual guides can help identify the location of specific components, their functions, and how they interact within the larger system.

Interpreting the Visual Elements

When examining a component layout, start by focusing on the symbols and lines that represent each part and its connections. Each symbol typically corresponds to a specific function or component type, while the lines show how different parts are linked. Carefully analyzing these visual cues will give you a clear understanding of the overall structure.

Identifying Key Components

Once the layout is understood, identifying key components becomes much easier. Each section of the system is usually labeled with numbers or letters that correspond to a list of parts or functions. By referencing this information, you can quickly locate any component in need of attention or replacement and determine its role in the overall operation.

Common System Components and Their Functions

Every mechanical system consists of several key elements, each playing a vital role in its overall functionality. Understanding these components and their specific functions is essential for proper maintenance and efficient operation. Below are some of the most common components found in such systems and their primary roles.

Essential Components

- Compressor: This component is responsible for pressurizing and circulating air within the system, enabling energy conversion.

- Generator: Converts mechanical energy into electrical power, supplying the system with the necessary electricity for various functions.

- Control Unit: Acts as the brain of the system, regulating the operation of various components based on performance data and user input.

- Heat Exchanger: Transfers heat between fluids, ensuring optimal temperature regulation within the system.

Supportive Elements

- Filters: Protect the system by removing contaminants from air and fluids, ensuring smooth operation.

- Valves: Regulate the flow of air, fuel, or fluids throughout the system, allowing precise control of pressure and temperature.

- Pipes and Hoses: Transport various fluids and gases between components, ensuring proper circulation throughout the system.

Understanding the function of each of these parts will help you identify potential issues and maintain smooth operation. Each piece plays a critical role in the overall system performance, and recognizing their function is key to effective troubleshooting.