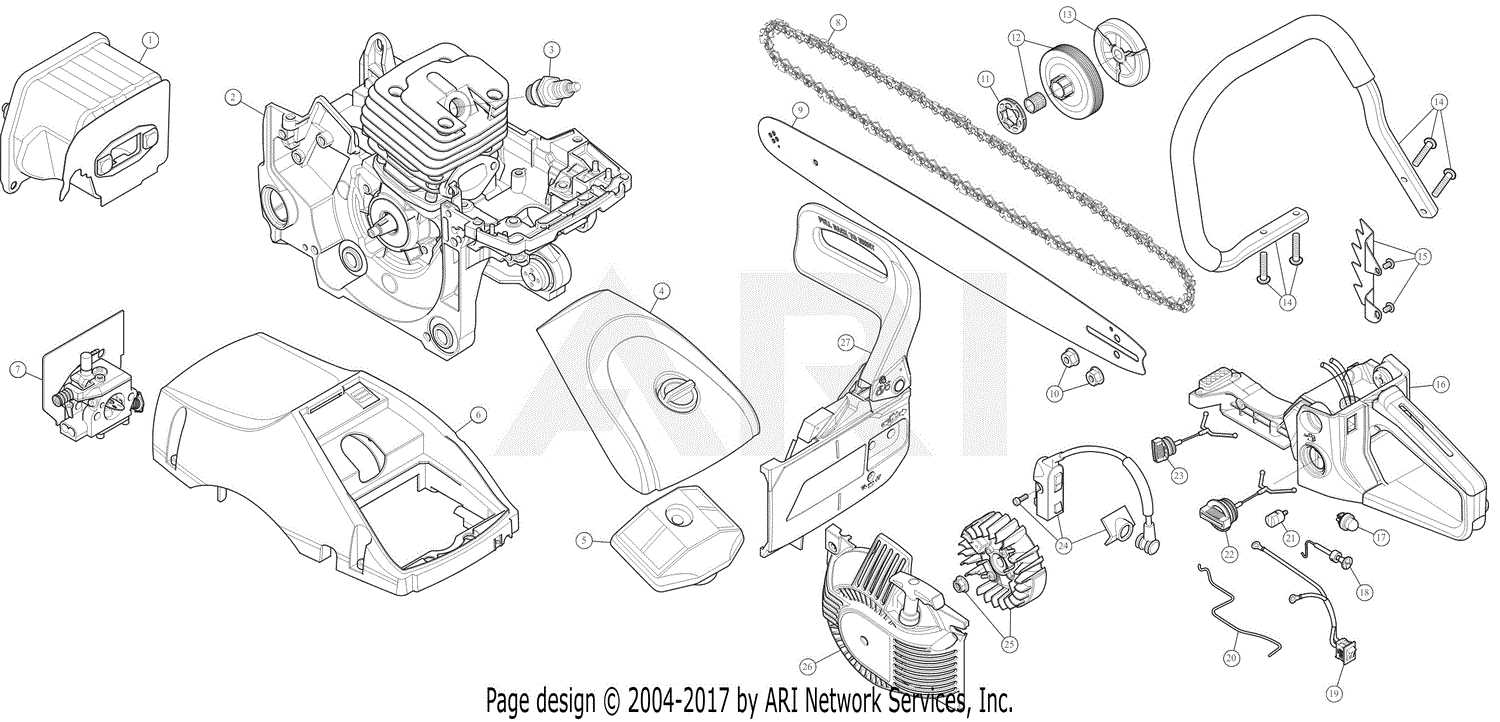

Proper maintenance of your power tool is crucial for ensuring its longevity and efficient performance. Understanding the components that make up the machine and how they interact is the first step towards effective troubleshooting and repair. This guide will provide you with the necessary knowledge to identify key elements and their functions within the equipment.

With a clear illustration of each crucial part, you will be able to assess wear and tear or any potential malfunctions. Accurate identification of each element can help avoid unnecessary replacements and repairs, ensuring that only the necessary components are addressed. Whether you are fixing a specific issue or conducting routine checks, familiarity with your tool’s build is invaluable.

We will walk you through the essential components, highlighting their roles and offering practical tips for maintaining them. Understanding these intricate details will not only save you time but also help extend the life of your equipment. Regular care is the key to keeping your tool running smoothly for years to come.

Understanding the 029 Stihl Chainsaw Parts

Each power tool is a complex system where various components work together to ensure smooth operation. A thorough understanding of these elements is essential for anyone looking to maintain or repair their equipment. By familiarizing yourself with the inner workings, you can identify issues quickly and effectively, reducing downtime and improving overall performance.

Key Components and Their Functions

The heart of any tool lies in its individual parts. These pieces serve specific roles, from powering the engine to ensuring proper fuel flow. Essential components such as the motor, air filter, and fuel system play critical roles in the tool’s performance. Each part has a unique function, and understanding their interactions helps in diagnosing problems more accurately.

How to Identify and Troubleshoot Issues

When something goes wrong, pinpointing the exact cause is easier when you know the roles of each part. Regularly inspecting these components allows for early detection of wear, damage, or misalignment. Knowing how to assess each part’s condition ensures you can tackle repairs in a timely manner, saving both time and money on unnecessary replacements.

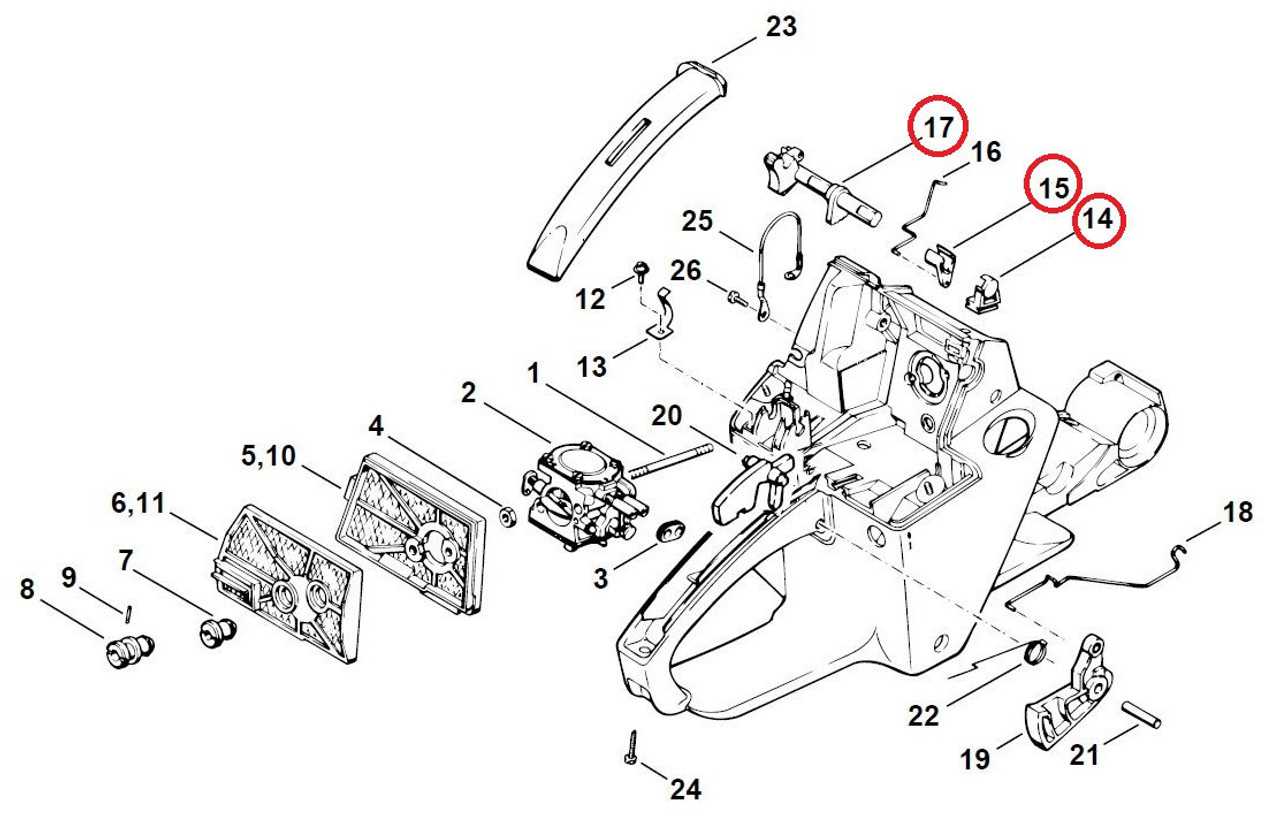

How to Read the Parts Diagram Effectively

Understanding how to interpret an illustration of your equipment’s components is essential for accurate troubleshooting and maintenance. These visual guides provide detailed representations of the tool’s assembly, helping you to identify each element and its connection within the system. Being able to read and comprehend these visuals will streamline the repair process, allowing you to make informed decisions when performing maintenance.

Start by focusing on the overall layout. Most diagrams are organized to represent the tool’s structure from the inside out, often showing both the exterior and internal parts. Key components are usually labeled with numbers or codes, which correspond to a list of descriptions or part numbers. Pay close attention to these labels, as they are vital in locating and identifying specific elements within the tool.

It’s also helpful to understand the flow of energy and mechanics within the system. Many diagrams include arrows to show how components interact with one another, such as fuel flow or air circulation. Recognizing these connections will allow you to better diagnose issues related to functionality and performance.

Common Issues with 029 Stihl Chainsaw Parts

When using any power tool, wear and tear on its components is inevitable. Over time, certain issues can arise that may affect its performance. Recognizing these common problems early can help prevent more serious damage and costly repairs. By knowing what to look for, you can ensure your equipment runs smoothly and effectively.

Fuel System Problems

A frequently encountered issue involves the fuel system, which can experience clogging or leakage. The fuel filter and lines may become dirty or worn, leading to poor fuel flow and, ultimately, engine performance issues. Regular inspection of the fuel system can help prevent these disruptions, ensuring the engine operates at its best.

Airflow and Spark Plug Issues

Another common problem is related to the airflow system and spark plugs. Clogged air filters can restrict airflow, causing the engine to overheat or run inefficiently. Similarly, spark plugs can wear out or become dirty, making it difficult for the engine to start or run smoothly. Checking these elements during routine maintenance can prevent performance degradation.