In any mechanical system, recognizing the intricate components and their functions is essential for proper operation and maintenance. A detailed look at the individual elements helps to ensure efficiency and prevent breakdowns.

Identifying key elements within the system can aid in diagnosing potential issues and simplifying the repair process. Understanding how each part interacts with the others is crucial for anyone working with such systems.

By reviewing a detailed schematic of the internal structure, one can gain insights into the placement and connections of the various components. This knowledge is beneficial not only for troubleshooting but also for optimizing overall performance.

Puma Air Compressor Parts Overview

Understanding the various components that make up a mechanical system is essential for ensuring its optimal functioning. Each element has a specific role that contributes to the overall operation, and recognizing these roles can help in efficient maintenance and repairs.

Key Elements of the System

Each system consists of different parts that work together in harmony. Some components control airflow, while others manage pressure or serve as protective elements. By identifying these crucial components, you can better understand how they interact and affect the system’s performance.

How Components Interact

The function of each part depends on its relationship with other elements. Some pieces are directly connected, while others act as support structures. A detailed understanding of how these parts collaborate ensures smoother operation and aids in troubleshooting when issues arise.

Understanding Key Components of Puma Compressors

Every machine relies on a series of interconnected elements, each with its own vital function. Recognizing these elements and how they contribute to the overall system ensures smooth operation and long-term reliability. A comprehensive understanding of the key components is crucial for anyone involved in maintenance or repair.

Essential Elements and Their Functions

The core elements that drive the system are designed to work together, with each playing a specific role. Some parts manage power flow, while others regulate pressure or provide protection. Identifying these critical components allows for more effective troubleshooting and upkeep.

Interconnection Between Components

The way these parts are connected impacts the overall efficiency of the system. Some elements work directly with others to control movement, while others act in a supporting role, ensuring safety and stability. Understanding these interconnections can make diagnosing problems and ensuring optimal performance much easier.

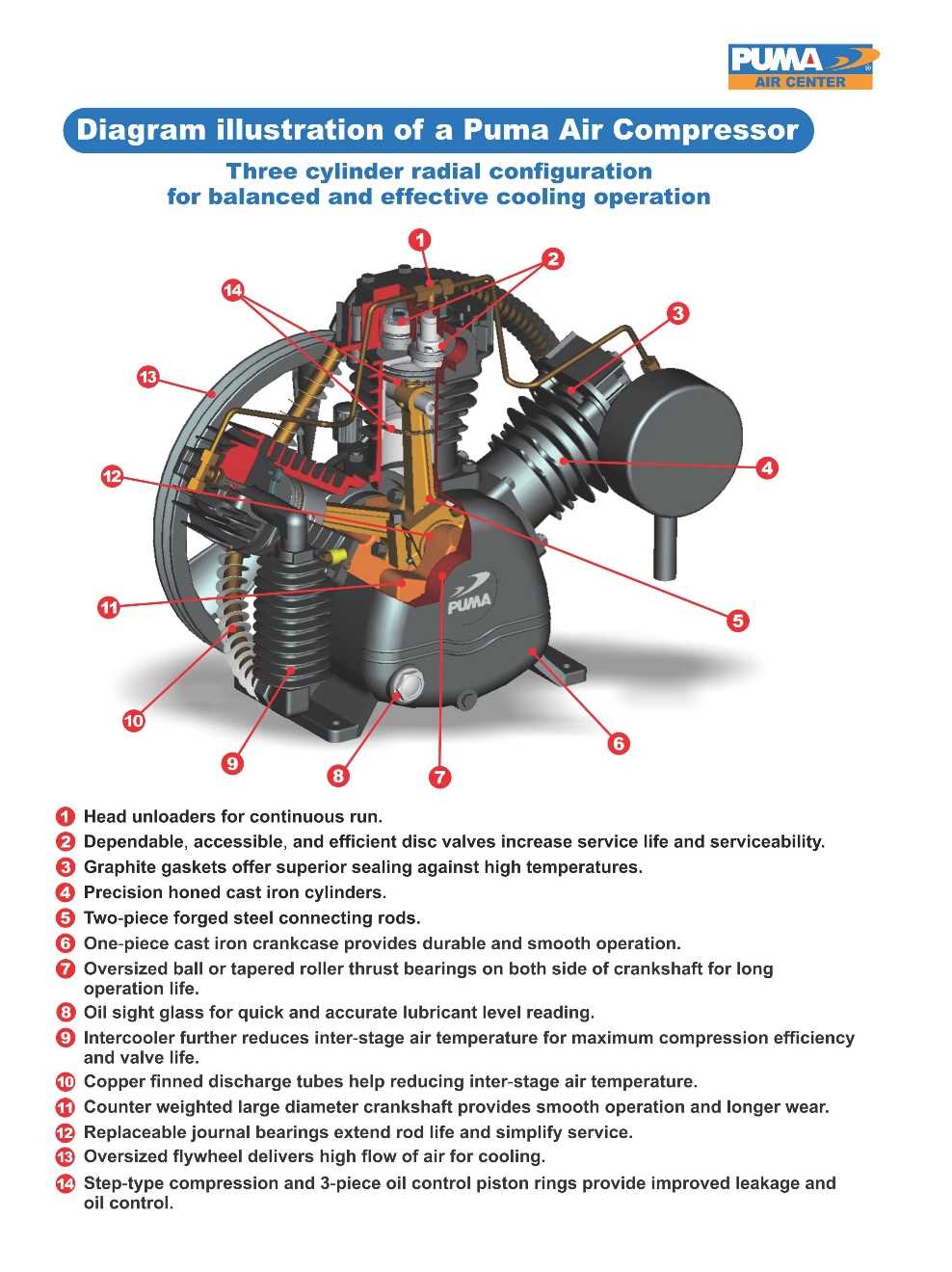

How to Read a Puma Air Compressor Diagram

Interpreting visual representations of a machine’s internal structure is key to understanding its operation and maintenance. These schematics offer a detailed view of how components are arranged and interact with each other, providing valuable insight into system functionality.

Breaking Down the Visual Representation

Each schematic is designed to show the relationships between different parts of the system. Key symbols represent specific components, and lines indicate how they are connected. Familiarizing yourself with these symbols is the first step to successfully interpreting any diagram.

Understanding Connections and Flow

The most important aspect of reading these visual guides is recognizing the flow of energy or materials through the system. Lines often represent the path of pressure or airflow, helping to trace how different elements work together to perform their tasks. Understanding this flow is essential for troubleshooting and optimizing system performance.