In every cooling system, there are several crucial elements that work in tandem to provide efficient performance. Each component plays a vital role in ensuring the overall effectiveness and longevity of the system. Knowing how these individual parts function and interact is essential for anyone interested in maintenance or repair tasks.

Understanding the functionality of these components gives insights into how they contribute to the refrigeration cycle. From the initial intake to the final release, each part has its responsibility in maintaining proper operation. Identifying and recognizing each component is key to troubleshooting or upgrading these systems efficiently.

When problems arise, understanding the basic layout and relationships between these key elements can make repairs more straightforward. In this guide, we will break down the major components, their roles, and how they contribute to the smooth operation of your cooling system.

Understanding Air Conditioner Compressor Components

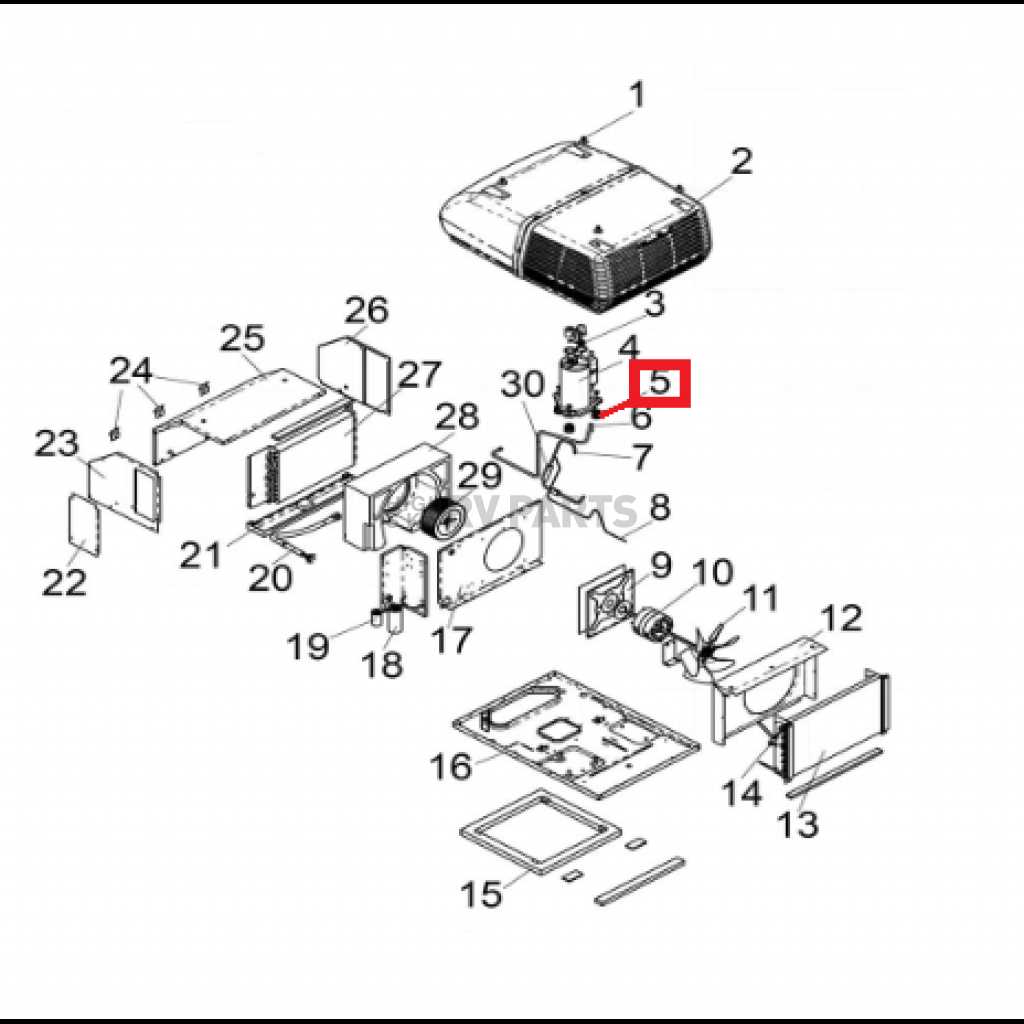

Within every cooling system, several essential elements work together to ensure efficient operation. These elements are responsible for circulating refrigerants and maintaining pressure within the system. Understanding how each component functions is crucial for anyone who wants to maintain or repair such systems. By identifying the key parts, it becomes easier to troubleshoot and ensure everything is functioning optimally.

The primary components of the system each have specific tasks that contribute to the overall refrigeration cycle. These parts are often interconnected, and each one plays a significant role in regulating temperature and pressure. Below is a breakdown of these key components and their functions.

| Component | Function |

|---|---|

| Pump | Moves refrigerant through the system, creating the necessary pressure for proper cooling. |

| Valve | Controls the flow of refrigerant, ensuring it moves in the right direction at the right time. |

| Motor | Provides the mechanical energy needed to operate various components, like the pump and fans. |

| Fan | Helps dissipate heat from the system and ensures proper airflow for cooling efficiency. |

| Heat Exchanger | Transfers heat from the refrigerant to the surrounding environment or vice versa, depending on the system’s cycle. |

Each of these elements is integral to the functioning of the entire system, and any malfunction can disrupt the balance, affecting performance. Knowing the role of each component helps in diagnosing issues and ensures the system runs smoothly for an extended period.

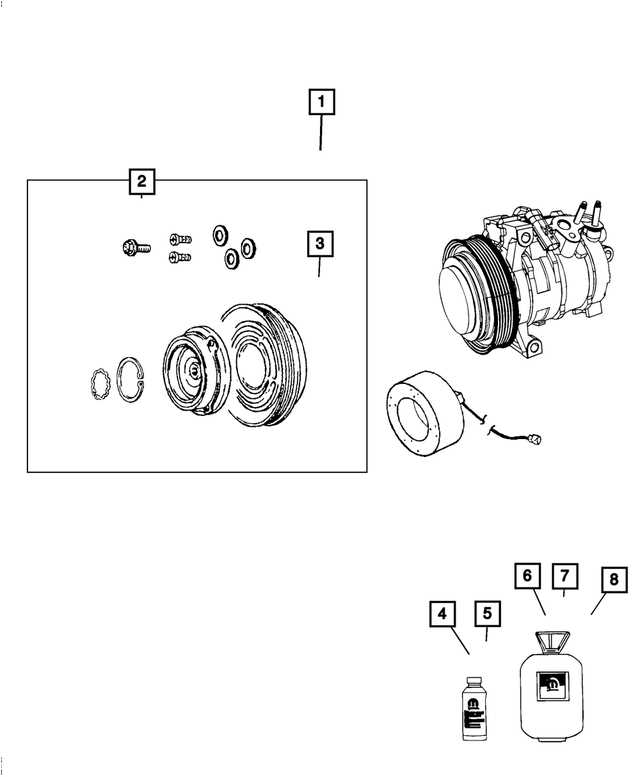

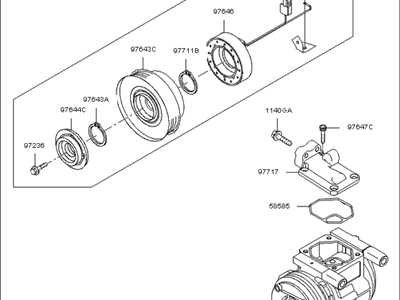

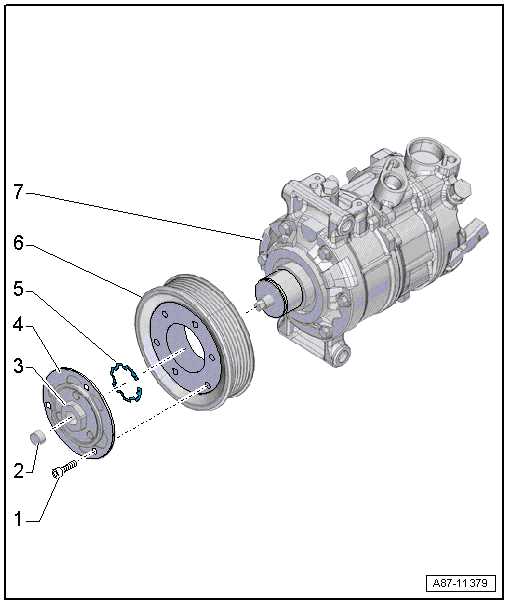

Key Parts of a Compressor and Their Roles

Every cooling system relies on several key components that work together to maintain efficient operation. These elements are responsible for regulating pressure, managing refrigerant flow, and facilitating heat exchange. Understanding the function of each part is crucial to ensuring the system’s effectiveness and longevity. Without these components working in harmony, the entire system’s performance could be compromised.

Each component has a specific role within the cycle, whether it’s ensuring proper pressure levels or managing refrigerant distribution. Here’s an overview of the critical parts and their functions:

| Component | Function |

|---|---|

| Motor | Generates the energy required to operate the system and power essential components like fans and pumps. |

| Pump | Moves refrigerant through the system, helping maintain the necessary pressure levels for effective cooling. |

| Valve | Controls the direction and flow rate of refrigerant, ensuring it moves properly through the system during different phases of the cycle. |

| Fan | Promotes airflow, helping dissipate heat from the system and ensuring continuous, efficient cooling performance. |

| Heat Exchanger | Transfers heat from the refrigerant to the surrounding environment or vice versa, enabling temperature regulation within the system. |

These components work together seamlessly to ensure that the cooling system functions optimally, providing reliable performance and maintaining desired temperatures. Understanding their roles can aid in diagnosing problems and ensuring the system is always working at peak efficiency.

How Air Conditioner Compressors Work

The cooling process in a system involves a series of phases that transform refrigerant from gas to liquid and back again. One of the critical steps in this cycle is the compression of the refrigerant, which allows for heat absorption and dissipation. Understanding how the components involved in compression operate helps in recognizing how heat is transferred and temperature is controlled within the system.

The main goal of compression is to increase the pressure of the refrigerant gas, enabling it to release heat effectively when it reaches the condenser. This process also ensures that the refrigerant flows in the correct cycle, enabling the cooling effect to occur. The following explains the key actions involved in this process:

The Compression Cycle

- Compression: The refrigerant enters the compressor in a low-pressure, gas state. The compressor’s motor increases the pressure and temperature of the gas, preparing it for heat exchange.

- Heat Dissipation: The high-pressure gas is directed to the condenser where it cools down, losing heat to the surrounding air. As the gas cools, it turns into a high-pressure liquid.

- Expansion: The high-pressure liquid then flows through an expansion valve, which reduces its pressure, causing it to cool further before entering the evaporator coil to absorb heat from the space being cooled.

Understanding the Role of Components

- Motor: Powers the compressor, providing the energy needed to force the refrigerant gas into a high-pressure state.

- Valve: Controls the refrigerant flow and directs it to the proper areas within the system at the correct times.

- Fan: Ensures that air flows over the components, aiding in the heat dissipation process and promoting the cooling effect.

This cycle repeats continuously, ensuring that the system maintains a consistent and effective cooling performance. By understanding these stages, it’s easier to see how the system maintains temperature regulation and why each component’s function is essential.

Explaining the Function of Each Part

In a cooling system, multiple components work together to facilitate the refrigeration cycle. Each part has a specific role that contributes to the efficient operation of the entire system. Understanding these functions is essential for troubleshooting and ensuring the longevity of the equipment. By recognizing the purpose of each component, it becomes easier to diagnose issues and keep everything running smoothly.

Key Components and Their Roles

- Motor: This component drives the system, providing the necessary mechanical energy to initiate and maintain movement throughout the cycle.

- Pump: The pump circulates refrigerant through the system, ensuring that it reaches the necessary areas at the correct pressure for effective cooling.

- Valve: The valve regulates the refrigerant’s flow by controlling its direction and pressure, ensuring it flows through the right parts at the right time.

- Fan: The fan helps promote airflow over key components, ensuring that heat is properly dissipated, allowing for efficient thermal regulation.

- Heat Exchanger: This element transfers heat between the refrigerant and the external environment, allowing the system to absorb or release heat as needed for cooling.

How Each Part Contributes to the Cycle

Each of these elements contributes to the larger process of regulating temperature. The motor powers the system, the pump circulates the refrigerant, and the valve directs its flow. The fan aids in the heat transfer process, while the heat exchanger ensures the proper release or absorption of thermal energy. Together, they form a highly coordinated system that maintains the desired conditions within the space being cooled.

Common Issues in Compressor Parts

Like any complex system, various components involved in cooling operations can experience malfunctions. These issues may range from simple wear and tear to more significant failures, which can disrupt the entire cycle. Understanding these common problems can help in identifying and resolving issues before they cause extensive damage or reduce efficiency.

Over time, components can suffer from both internal and external factors that affect their performance. These include mechanical failure, clogging, loss of refrigerant, or problems with energy supply. Regular maintenance and inspections are crucial to minimizing the impact of such issues and ensuring that all parts function correctly.

- Motor Failures: The motor, responsible for powering the system, may suffer from overheating or electrical issues, leading to a total breakdown or inefficiency.

- Pump Malfunctions: If the pump is damaged, refrigerant flow may be restricted, causing inadequate cooling and possible system shutdowns.

- Valve Leaks: Leaking valves can cause a drop in pressure, leading to inefficiencies and possibly allowing refrigerant to escape, resulting in poor performance.

- Clogged Filters: A clogged filter can block airflow, causing overheating and reducing the system’s cooling capacity.

- Wear on Heat Exchanger: Over time, the heat exchanger may degrade, reducing its ability to transfer heat effectively, leading to poor cooling performance.

Addressing these common issues early on through proper maintenance can significantly improve the system’s reliability and longevity. Regular inspections can help identify signs of damage, allowing for timely repairs and preventing more costly fixes down the line.