When it comes to maintaining and repairing your outdoor cleaning equipment, understanding the various components is crucial for efficiency and longevity. A clear understanding of the internal structure ensures that you can quickly identify issues, perform repairs, or replace worn-out elements without unnecessary delays.

By learning how different elements function together, you can improve the overall performance of your machine. Whether you are a professional or a casual user, mastering the mechanics behind these devices allows for smoother operation and fewer interruptions during use.

Regular maintenance is key to preventing common malfunctions and extending the lifespan of your equipment. With the right knowledge, you can troubleshoot problems with confidence, ensuring that your machine operates at peak performance each time it is used.

Understanding the Pressure Washer Parts

To operate your cleaning equipment efficiently, it is essential to comprehend the various components and their functions. Each element of the system plays a critical role in ensuring smooth operation and optimal results. Knowing how these individual components work together can help you troubleshoot issues, perform maintenance tasks, and even replace parts when necessary.

The Key Elements of the Machine

The core of any cleaning equipment is its motor and pump, which work in unison to deliver the required force for cleaning. The motor generates the power needed, while the pump regulates the flow of water. Understanding how these components interact is vital to ensuring your machine runs at peak performance.

Identifying Common Components

Other essential components include hoses, nozzles, and connections, each of which serves a unique purpose. The hoses carry water from the source to the unit, while the nozzles control the spray pattern and intensity. These elements must be inspected regularly to prevent blockages, wear, and other malfunctions.

By understanding these crucial parts, you can enhance the efficiency of your equipment and extend its lifespan. Regular inspection and maintenance are key to keeping everything in working order.

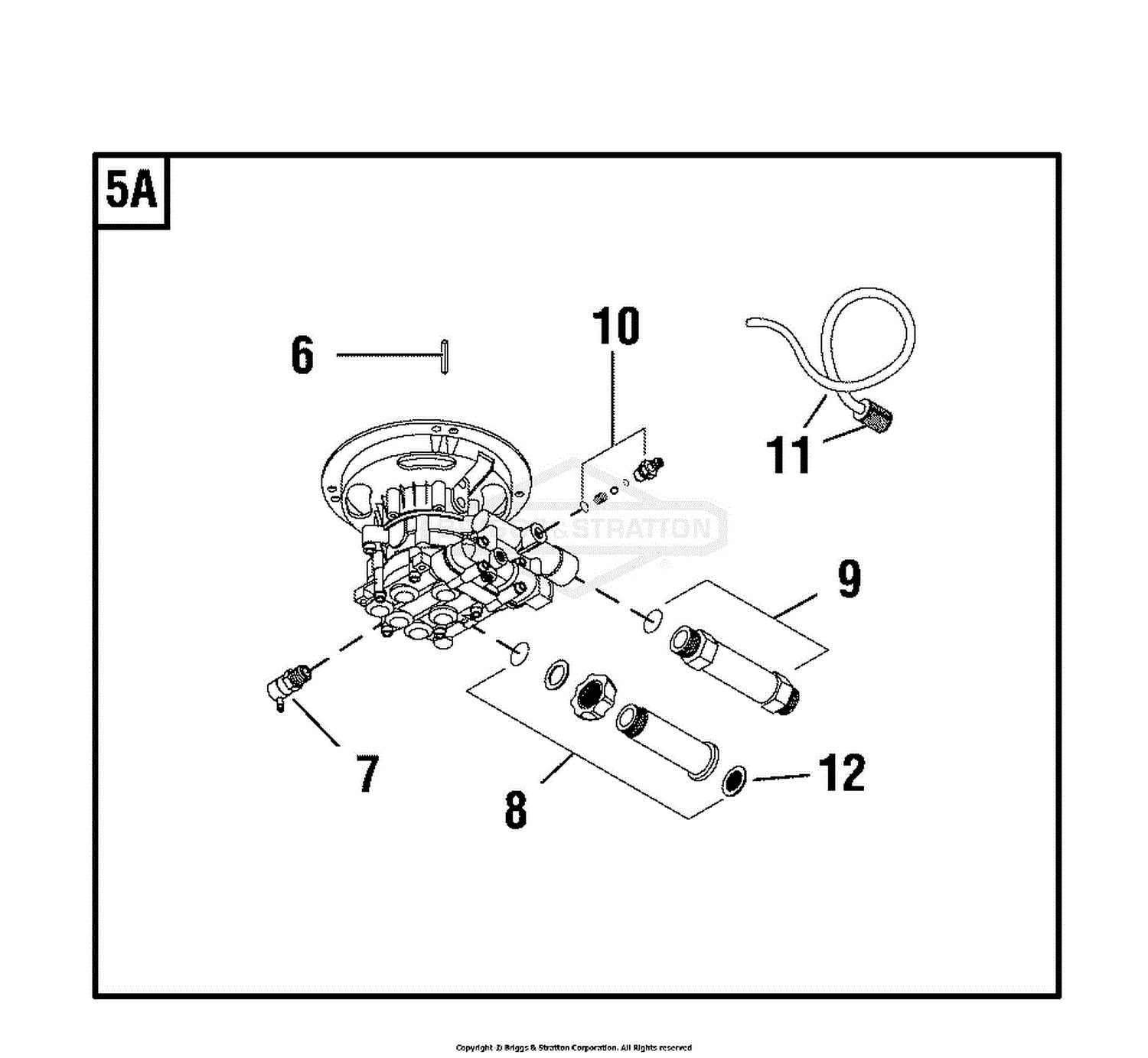

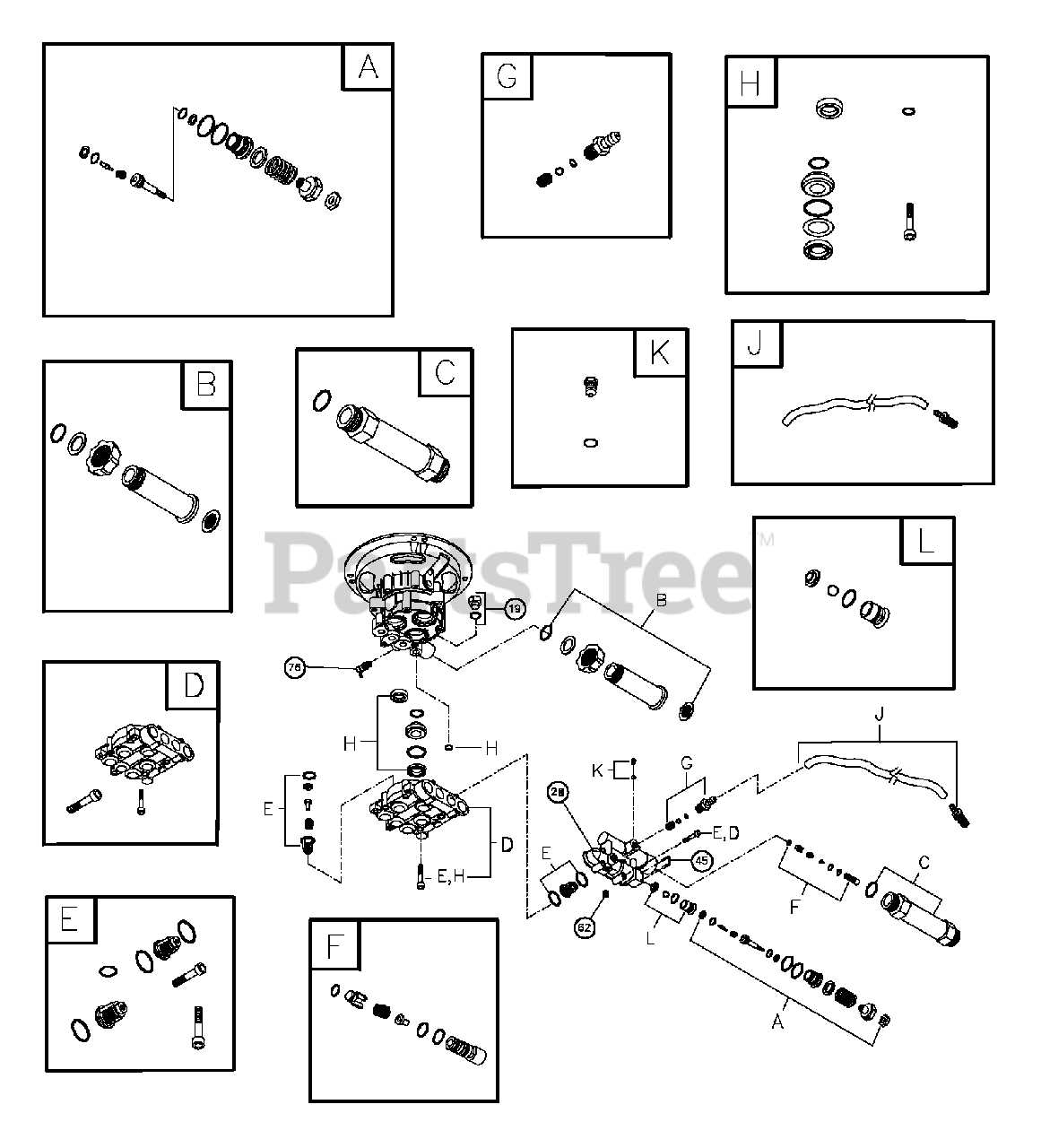

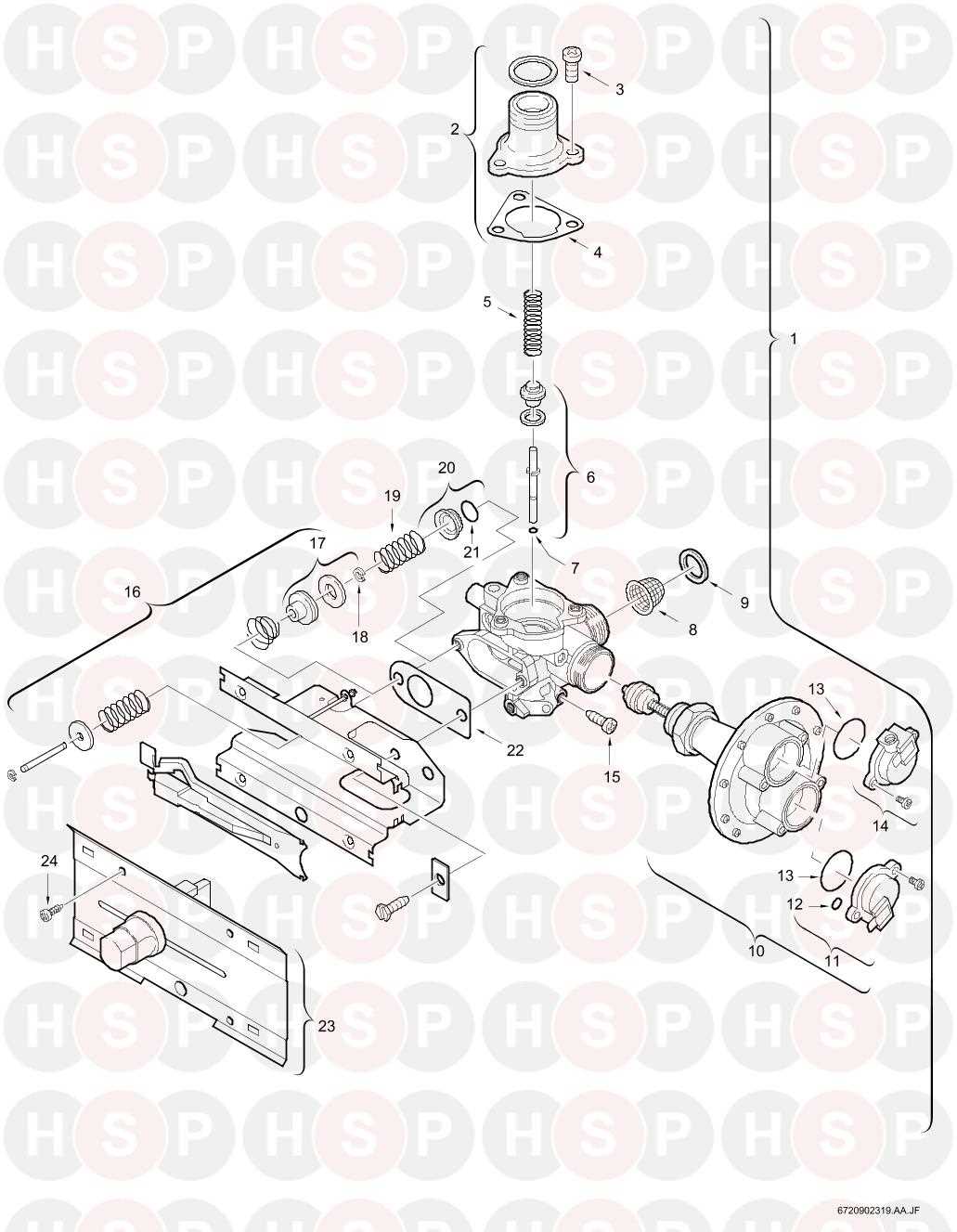

How to Read the Parts Diagram

Understanding how to interpret the visual representation of your machine’s internal components is crucial for efficient maintenance and repairs. A well-detailed schematic can help you quickly locate parts, identify their functions, and figure out the necessary steps to resolve any issues.

The diagram typically consists of a detailed illustration showing each individual element of the device. Each part is usually labeled with a number or code that corresponds to a list, which provides more detailed information. To make the most out of this guide, it is important to familiarize yourself with the layout and structure of the machine before referring to the visual.

Additionally, pay attention to the symbols and notations that are used to indicate specific functions or positions. These marks will help you understand how the components interact and guide you in disassembling or reassembling the equipment correctly.

Common Issues with Pressure Washer Components

Various problems can arise with the components of outdoor cleaning devices, often leading to decreased performance or complete malfunction. Recognizing common issues early on can save time and money by preventing further damage. It is important to know which elements are prone to wear and tear so you can address these problems before they escalate.

One frequent issue is a decrease in water flow, which can be caused by clogged hoses or faulty connections. In some cases, the motor may fail to start, which could be related to electrical malfunctions or fuel supply issues. Additionally, improper assembly or damaged seals can lead to leaks, reducing efficiency and performance.

Another issue to consider is the buildup of dirt or debris in critical components, which may impair functionality or cause overheating. Regular maintenance and periodic checks of these components are essential to avoid these common problems and ensure that your device operates smoothly.

Identifying Faulty Parts Easily

Spotting damaged or malfunctioning components quickly is essential to keeping your cleaning equipment in good working condition. By recognizing common signs of wear and tear, you can avoid extended downtimes and unnecessary repairs. Understanding what to look for ensures that you can address issues promptly before they affect overall performance.

One of the first indicators of a problem is unusual noise or vibrations during operation. If you notice anything out of the ordinary, it could signal that something within the internal system is malfunctioning. Additionally, pay close attention to reduced efficiency, such as weaker water flow or difficulty starting the machine, which often points to issues with the motor or connections.

Inspecting gaskets, hoses, and seals is another effective way to detect faults. Cracks, leaks, or visible damage to these components can directly impact performance. Regularly checking these areas and replacing any worn-out parts is essential for ensuring smooth operation.

Maintaining Your Cleaning Equipment

Proper maintenance is the key to ensuring that your outdoor cleaning tool operates efficiently and lasts for years. By following a regular maintenance routine, you can prevent common malfunctions, enhance performance, and minimize the need for costly repairs. Here are a few essential steps to keep your device in optimal condition.

Routine Maintenance Tasks

- Check and clean the nozzles regularly to prevent clogs that could impact performance.

- Inspect the hoses for leaks, cracks, or kinks and replace damaged sections as needed.

- Ensure the motor is properly lubricated to reduce wear and maintain smooth operation.

- Examine the fuel system for any signs of buildup or damage that could lead to inefficiency.

Storage and Preservation Tips

- Store your equipment in a cool, dry place to protect it from extreme temperatures and moisture.

- Before storing, drain any remaining fuel to prevent clogging or corrosion in the system.

- Cover the unit with a protective tarp to shield it from dust and dirt during periods of inactivity.

By staying on top of these simple yet important maintenance steps, you can keep your equipment running smoothly for an extended period, ensuring that it is always ready for use when needed.