When maintaining and repairing your equipment, it’s essential to have a clear understanding of its structure. Knowing the key elements and their roles can save you time and effort when troubleshooting or replacing faulty parts. Whether you’re a professional or a DIY enthusiast, having the right knowledge makes the process smoother and more efficient.

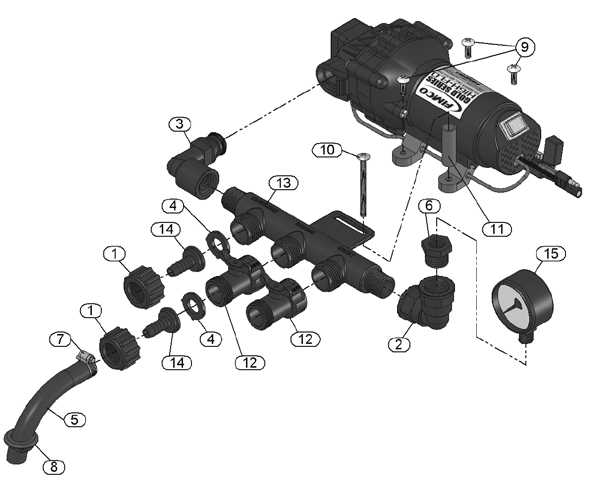

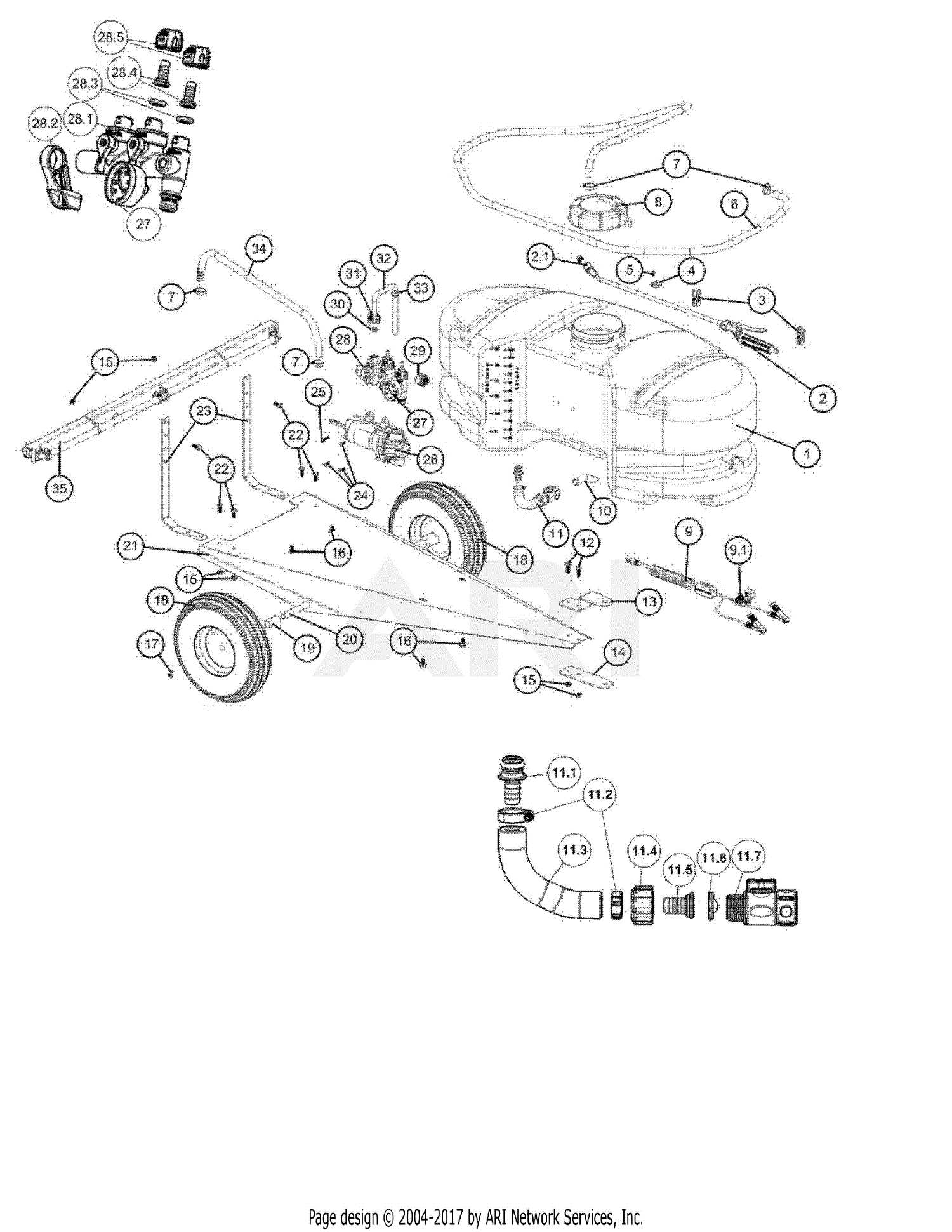

Detailed reference guides can be incredibly helpful for identifying various components within the system. These resources allow you to locate the parts you need and ensure that everything functions correctly. A visual reference can also make assembly and disassembly much easier, reducing the chances of error.

Being familiar with the most common issues that arise in equipment maintenance will also aid in the process. Knowing what to expect and how each part interacts with others helps ensure a faster and more accurate repair.

Fimco 25 Gallon Sprayer Overview

Understanding the structure and functionality of your equipment is crucial for proper use and maintenance. This type of device is designed for efficient liquid distribution, making it ideal for various tasks such as fertilizing, pest control, or irrigation. It operates by using a pressure system to ensure a consistent and even flow of liquid across a surface or area.

Key Features and Functionality

The machine is designed with several key components that work together to deliver effective results. These include a durable tank, pressure pumps, hoses, and nozzles. Each part is crafted to withstand regular use while ensuring that liquids are distributed smoothly. The overall system is engineered for ease of use, making it suitable for both large-scale applications and smaller projects around the garden or farm.

Maintenance and Care

Regular maintenance of the device ensures that it continues to operate at its peak performance. Checking for wear and tear, cleaning filters, and replacing any worn-out components are essential steps to avoid malfunction. By understanding the roles of each part and keeping track of their condition, you can extend the life of your equipment and keep it running efficiently.

Understanding the Parts of a Sprayer

A thorough understanding of the various components of your equipment helps ensure smooth operation and longevity. Knowing each piece’s function allows for easier troubleshooting and more effective maintenance. The overall system is designed to work seamlessly, but each element plays a unique role in its efficiency.

Key Components and Their Roles

- Tank: Holds the liquid to be distributed, ensuring it is stored securely until needed.

- Pressure Pump: Pressurizes the liquid, enabling it to flow through the system at the desired rate.

- Hoses: Transport the liquid from the tank to the nozzle for distribution.

- Nozzles: Control the spread and pattern of the liquid, allowing for precise application.

- Filter: Prevents debris from clogging the system, ensuring consistent performance.

Why Each Component Matters

Each element within the system contributes to the overall efficiency and effectiveness of the equipment. Regular inspection and maintenance of these parts can prevent issues such as clogging, uneven distribution, and leaks. Understanding their roles helps users identify when a component needs repair or replacement, minimizing downtime and improving the overall operation of the machine.

How to Identify Replacement Components

Recognizing when a component needs to be replaced is essential for keeping your equipment functioning properly. Identifying the correct replacements can prevent downtime and costly repairs. Knowing where to look and what signs to check can make the process much simpler and more efficient.

Signs of Wear and Tear

Some parts may show clear signs of damage or wear, which can help you identify the need for a replacement. Common indicators include:

- Cracks or Leaks: Any visible cracks or leaks around the system can signal that a part is no longer functioning properly.

- Loss of Pressure: If you notice a decrease in pressure or uneven distribution, the pump or hoses may need attention.

- Clogging: Clogged nozzles or filters can significantly reduce efficiency, indicating a need for cleaning or replacement.

Finding the Correct Replacements

Once you have identified a damaged or worn part, it’s crucial to find the right replacement. Refer to the equipment’s manual or an online resource for specific part numbers and compatibility. Ensure that the new part matches the specifications of the original to maintain the system’s overall performance.