Maintaining and repairing lawn care machinery requires a thorough understanding of its internal structure. The layout of essential elements within the equipment plays a crucial role in ensuring optimal functionality and durability. By becoming familiar with the different parts, users can troubleshoot effectively and ensure their machines operate smoothly.

Detailed schematics offer valuable insights into how each component is connected and functions together. Whether for routine maintenance or during repair processes, knowing how parts interact can significantly reduce downtime and improve overall efficiency. Understanding these layouts allows owners to make informed decisions about repairs and upgrades.

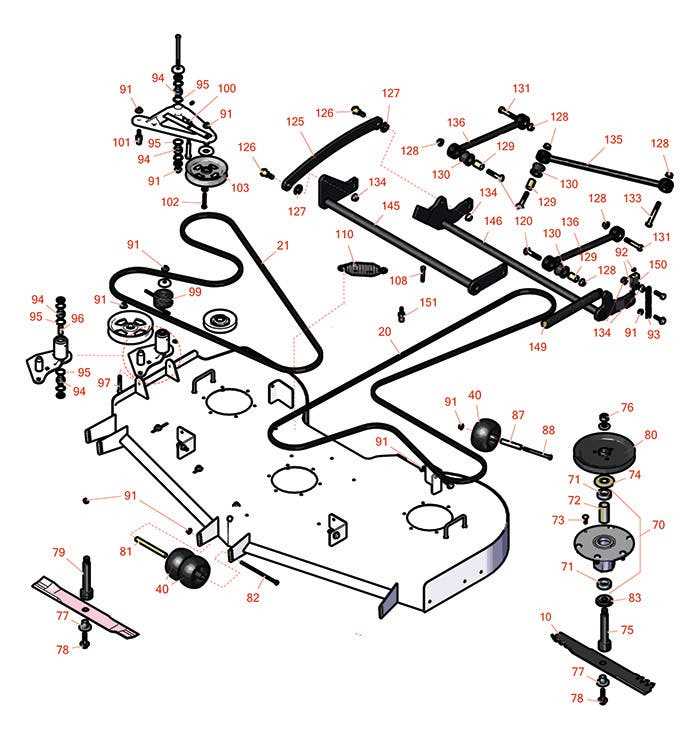

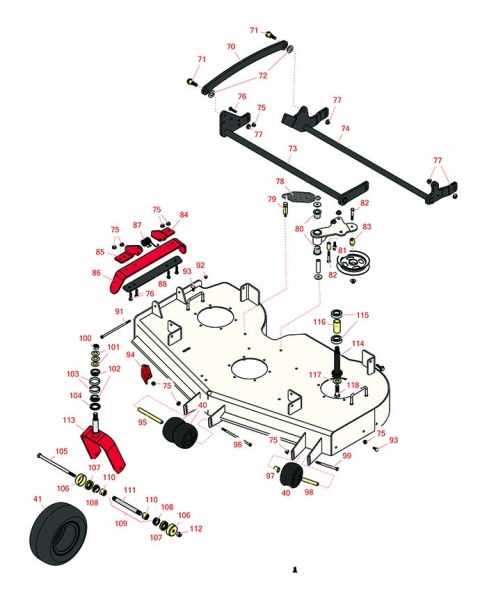

Toro Z Master Parts Breakdown

Understanding the layout and structure of essential components within your equipment is vital for proper maintenance and troubleshooting. Each element plays a specific role in the overall function, and identifying these pieces can help ensure a longer lifespan and more effective operation. By breaking down the individual sections, users can address potential issues and optimize the performance of their machines.

Key Mechanical Components

Mechanical components like the engine, transmission, and drive system work in unison to provide power and mobility. These pieces are often the first to show wear, especially with regular use. Knowing their function and how to replace or repair them is crucial for maintaining machine longevity.

Electrical and Control Systems

Alongside mechanical parts, electrical systems control critical operations like ignition, safety features, and power distribution. A thorough understanding of wiring, switches, and sensors allows for quick identification of faults and helps prevent costly repairs in the future.

Understanding Toro Z Master Components

Familiarity with the inner workings of machinery is key to ensuring proper care and efficient performance. Each piece of equipment contains various interconnected parts, each serving a specific function. Understanding how these components work together is essential for both maintaining the equipment and addressing any mechanical issues that may arise.

Mechanical System Essentials

The heart of any lawn care equipment lies in its mechanical system. The engine, drive system, and wheels form the foundation for operation. These critical elements work in unison to provide power and mobility, and understanding their functions ensures that issues related to power loss or movement can be quickly diagnosed.

Electrical System Overview

The electrical system manages several key functions, including starting the engine and controlling various sensors. Familiarity with wiring, fuses, and control switches ensures you can troubleshoot electrical failures effectively, helping maintain machine safety and performance.

How to Read the Toro Z Master Diagram

Reading a machine layout can be a daunting task, but understanding it is essential for effective maintenance and repairs. These layouts provide a clear visual representation of how components are organized and how they interact with one another. By interpreting these schematics correctly, users can identify parts that need attention and address issues quickly.

Identifying Key Components

Each diagram highlights crucial elements such as the engine, transmission, and electrical systems. Familiarizing yourself with the symbols and labels used in the layout is the first step to interpreting it accurately. Once you recognize the components, you can trace their connections and understand their functions within the machine.

Understanding the Connections

In these layouts, lines and arrows often represent connections between components. These connections indicate how power flows, how parts communicate, and where maintenance is needed. By following these lines, users can pinpoint where issues might occur, such as electrical faults or mechanical failures, and address them efficiently.