In any engine, the movement and interaction of internal components are essential for converting energy into mechanical power. Each element plays a vital role in ensuring smooth operation and optimal performance. Understanding the configuration and function of these components is crucial for effective maintenance and troubleshooting.

Identifying the key elements of an engine helps to improve performance and durability. From the initial motion to the transfer of force, these parts work together in harmony. A clear understanding of their design and purpose provides valuable insights for repairs and upgrades.

Knowledge of engine mechanics is not just for professionals; it empowers enthusiasts to make informed decisions and extend the lifespan of their equipment. Recognizing the interdependence of these elements is fundamental for anyone involved in engine management or repair.

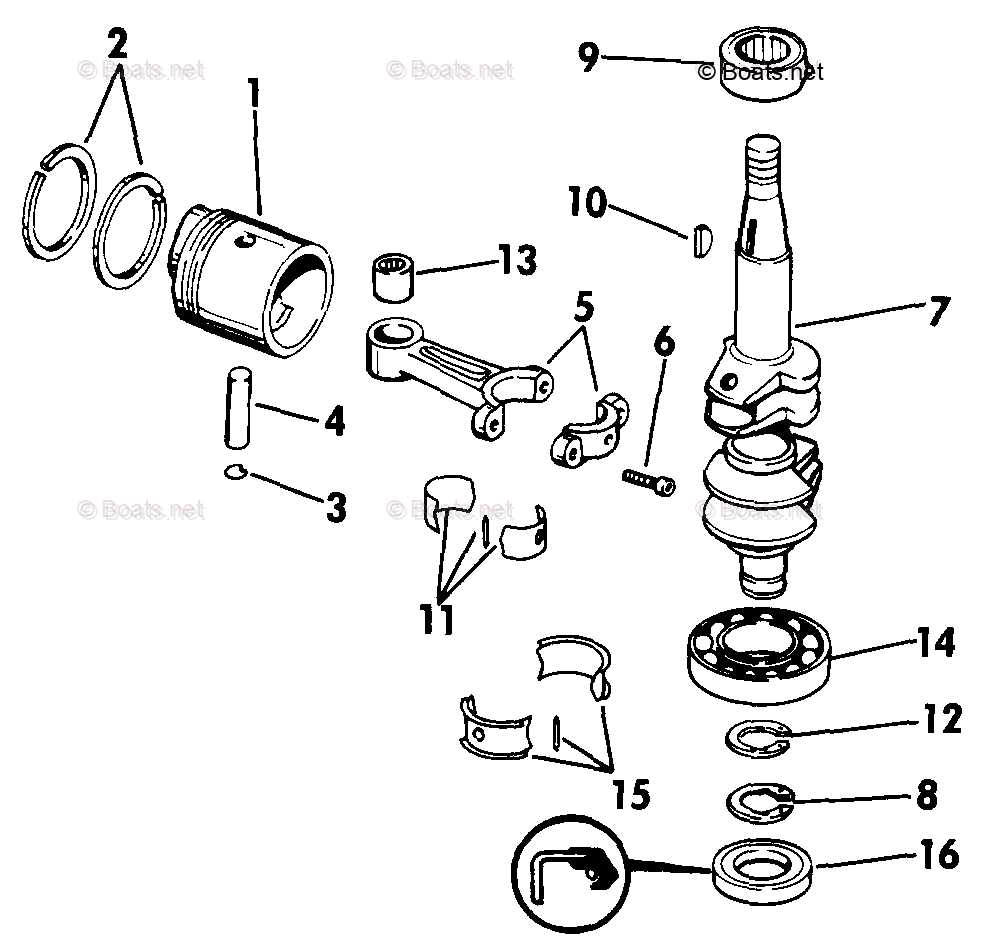

Understanding the Assembly of Engine Components

The internal structure of an engine is designed for optimal energy conversion, with each component serving a specific function. These crucial elements are responsible for translating fuel into mechanical force. By examining the layout and function of each segment, it becomes clear how they work together to generate power efficiently and effectively.

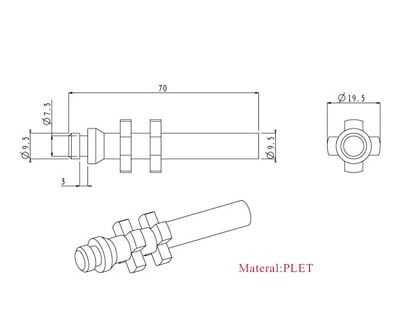

Key Elements in the Internal Mechanism

The central unit of an engine assembly is composed of several interconnected pieces that facilitate the transfer of motion and energy. Each piece has a precise role, from initiating movement to controlling the force produced during combustion. A solid understanding of how these elements interact is necessary for proper maintenance and performance enhancement.

Functionality and Efficiency in Operation

To achieve maximum efficiency, the design of these components takes into account factors like heat distribution, pressure management, and durability. By ensuring that every element is working in harmony, engines can function at their peak performance levels, reducing wear and enhancing longevity.

Key Components of a Piston Engine

The engine relies on several crucial elements working in tandem to transform fuel into mechanical energy. These components must operate smoothly, as they are directly involved in the generation of power and the efficient running of the engine. Each piece plays a specific role in managing combustion, transferring motion, and ensuring the engine runs without issues.

From the central unit that converts pressure into movement to the surrounding components that control various aspects of fuel and airflow, every element is critical for the overall performance. Understanding how these parts function together is essential for proper engine maintenance and repair.

How Engine Components Affect Performance

The efficiency and power of an engine are directly influenced by the design and condition of its internal elements. Each component contributes to the overall functioning, ensuring that energy is converted from fuel into mechanical motion. Any imbalance or wear in these key segments can lead to performance issues, affecting everything from acceleration to fuel efficiency.

The way each element interacts–whether it’s controlling the pressure within the combustion chamber or managing heat distribution–has a significant impact on the engine’s output. Proper maintenance and understanding of these components are vital for maximizing the engine’s potential and extending its lifespan.