Understanding how to identify and replace specific components in your tools or equipment can significantly enhance the repair and maintenance process. Knowing the structure of your machine and how different parts work together ensures smoother operation and longevity. This knowledge is essential for anyone looking to keep their tools in top condition.

By referring to detailed visual guides, you can easily locate the exact piece you need, whether for fixing, upgrading, or replacing worn-out parts. These resources are designed to simplify the identification process, making it easier for both beginners and experienced users alike. With accurate information, you can reduce downtime and avoid unnecessary confusion during repairs.

Proper identification of each individual part is key to successful repairs. It helps in finding the correct replacements, saving time, and reducing errors. This is a crucial step for maintaining the efficiency and performance of your equipment over time.

Understanding Craftsman Parts Diagram

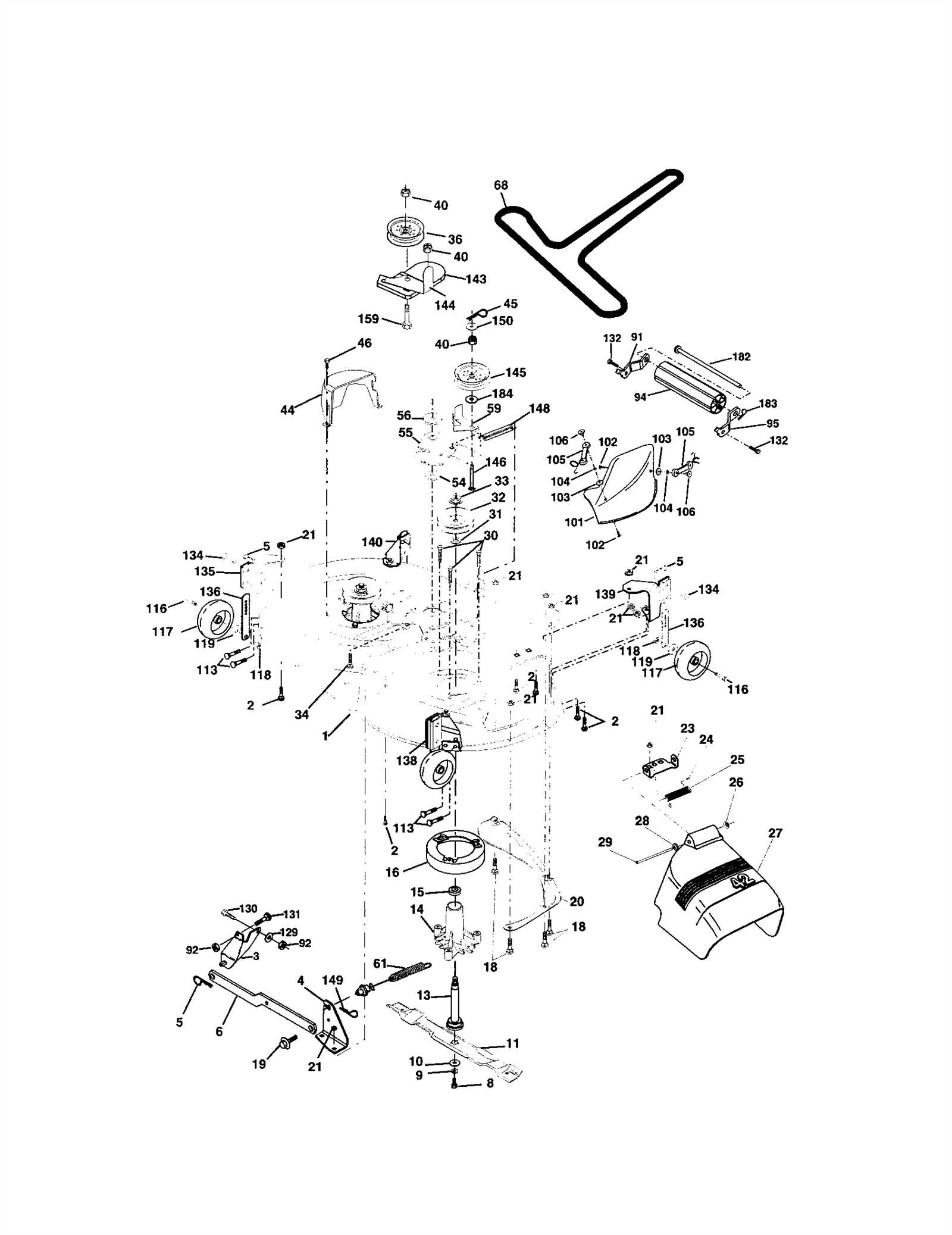

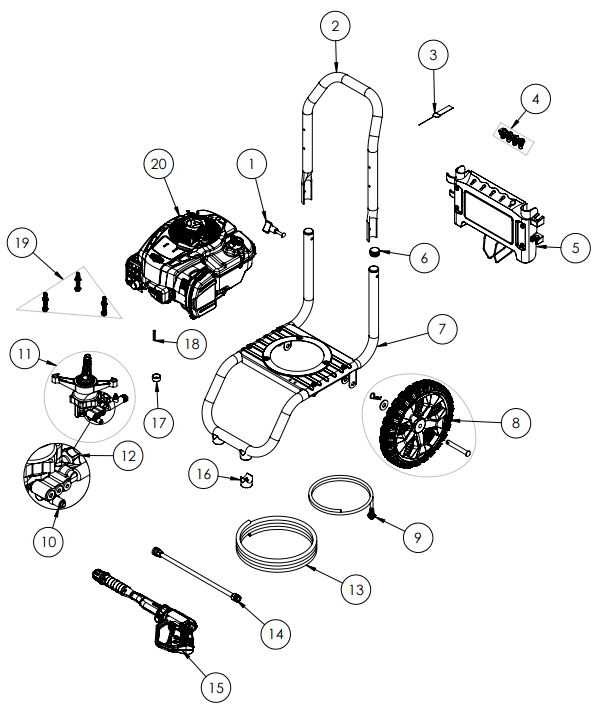

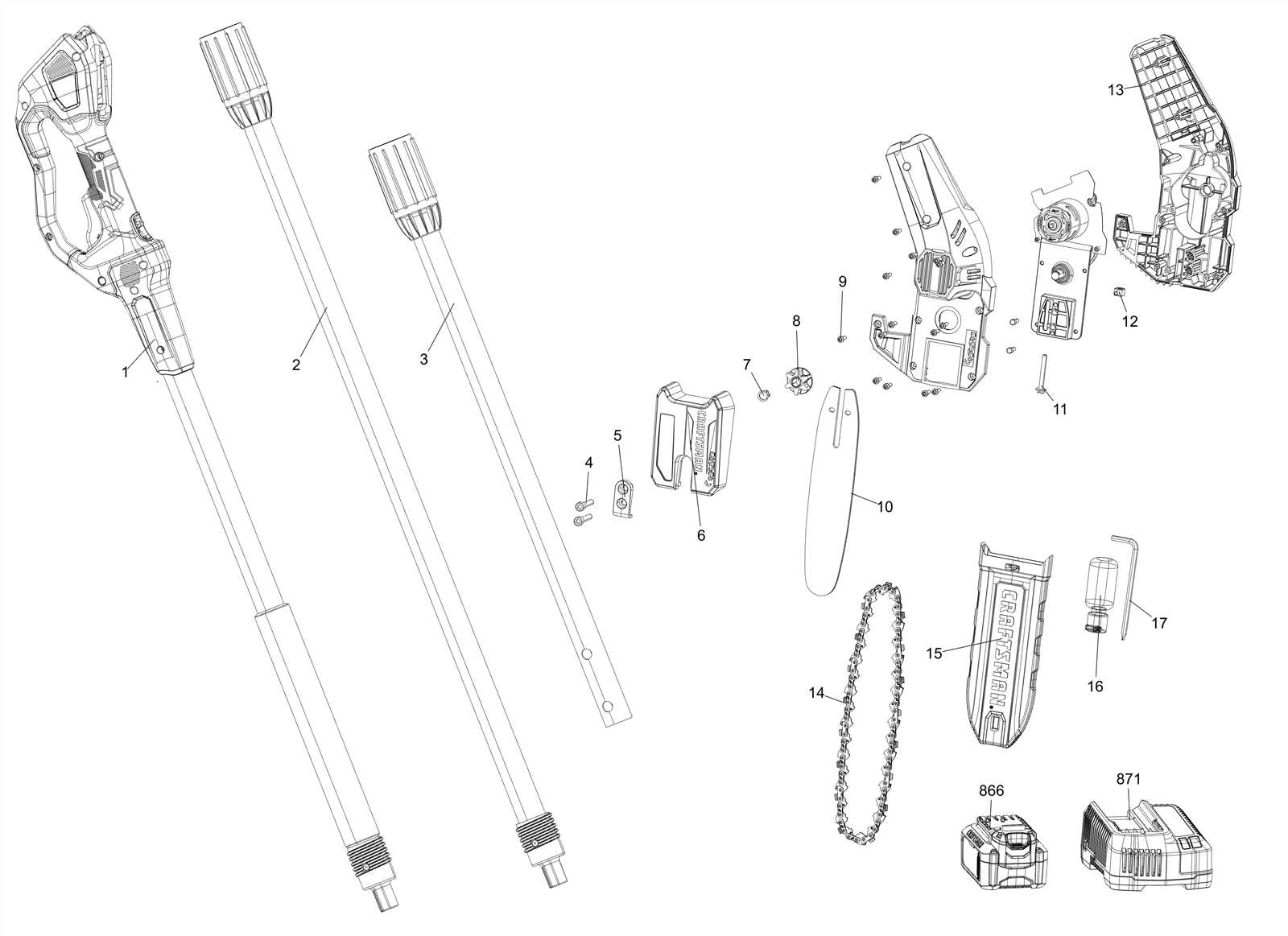

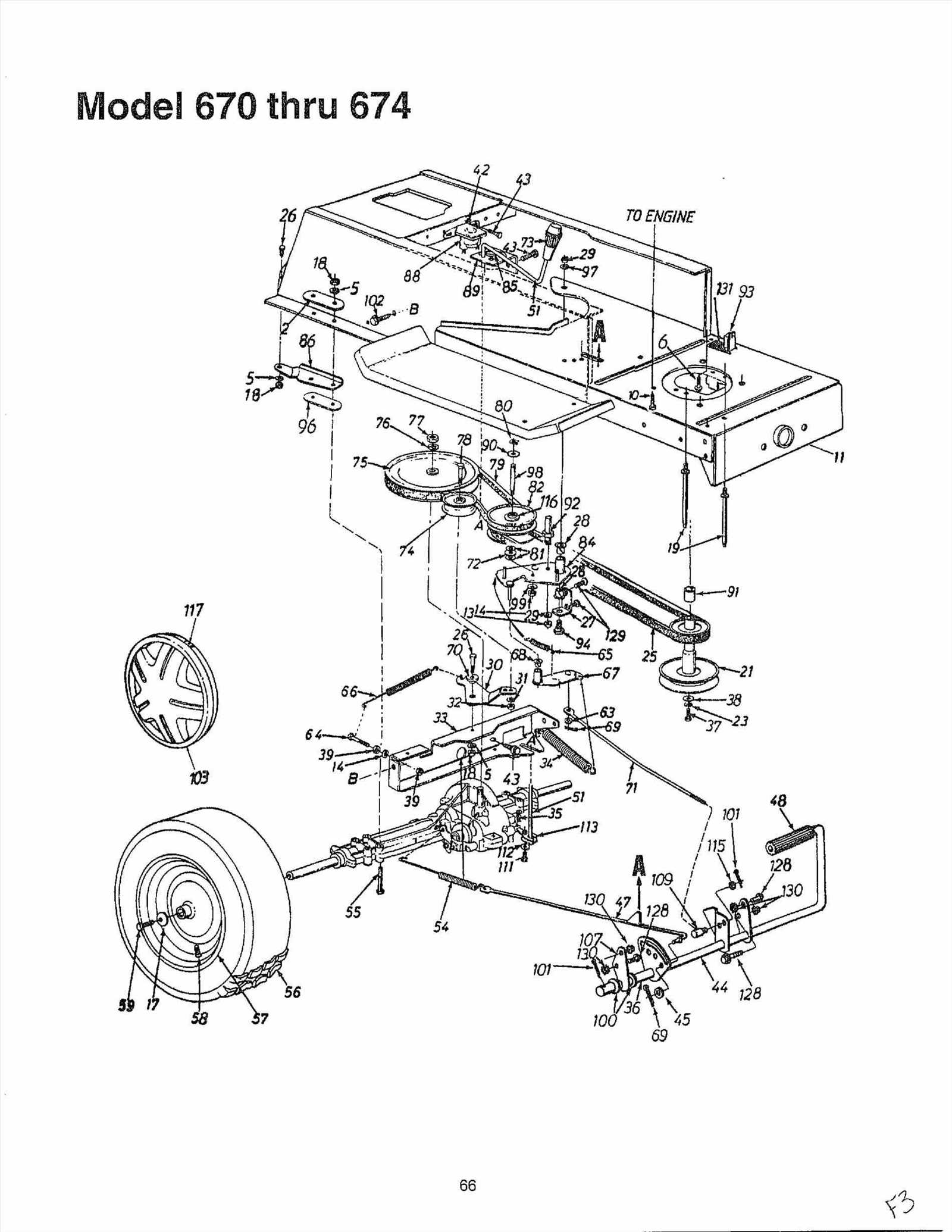

To successfully repair and maintain your equipment, it is essential to have a clear understanding of its internal structure and individual components. A well-structured visual guide allows you to identify each element, ensuring that you can recognize the parts needed for replacements or adjustments. By following these detailed illustrations, users can simplify the repair process and avoid unnecessary confusion.

These resources often feature clear labels, arrows, and item numbers, providing precise information about the location and function of each component. Knowing how the different elements fit together allows for a more efficient repair process and helps prevent damage to other parts during disassembly or reassembly.

By familiarizing yourself with these visual references, you can gain confidence in maintaining your equipment. This knowledge also helps in avoiding costly service calls and ensures that you can perform routine maintenance with ease and accuracy.

How to Use a Craftsman Parts Diagram

Using a visual guide for identifying specific components can greatly simplify the repair or replacement process. These references provide a detailed layout of each part within the system, helping you pinpoint the exact pieces required for any task. Understanding how to navigate these resources is key to performing efficient maintenance and ensuring correct installations.

Step-by-Step Identification

Start by locating the section of the guide that corresponds to your equipment model. Each part will be marked with a unique identifier or number, allowing you to cross-reference it with the required components. Focus on the details and ensure you understand where each item fits within the overall assembly before proceeding with removal or replacement.

Using the Guide for Replacement

Once you’ve identified the needed parts, check their availability and compatibility with your equipment. This visual resource will also indicate any specific assembly instructions or warnings. By following the guide carefully, you can avoid costly mistakes and ensure that replacements are installed correctly, preserving the functionality of your equipment.

Benefits of Accurate Parts Identification

Accurate identification of components plays a crucial role in the efficiency and success of repairs. Understanding exactly which elements need replacement or attention ensures that tasks are completed correctly the first time, saving time and effort. This process not only improves the functionality of your equipment but also extends its lifespan by addressing issues promptly and accurately.

Having the right information reduces the risk of errors during repairs. When each item is properly identified, you minimize the chances of installing incorrect or incompatible pieces, which could lead to additional damage. This precision leads to smoother operation and prevents the need for frequent fixes, ultimately saving both money and resources.

Moreover, accurate identification makes the repair process more straightforward, even for those with minimal experience. With clear guidance, anyone can confidently tackle maintenance tasks without the worry of missing a crucial step or part, ensuring better outcomes and a more reliable machine overall.