When working with complex machinery, understanding its core components is essential for effective maintenance and troubleshooting. Each system relies on a series of interconnected elements that work together to ensure optimal performance. Familiarizing yourself with these elements can significantly improve your ability to address any issues that may arise and enhance the lifespan of the system.

Comprehending the structure of your machinery helps in identifying individual parts and understanding how they contribute to the overall function. A detailed breakdown of these components provides clarity on where and how specific functions are carried out, offering insight into what needs attention during regular checks or repairs.

Knowing how to interpret technical illustrations that map out these components is a valuable skill. It enables you to locate the exact area requiring service, replace faulty elements with ease, and ensure that your equipment continues to perform efficiently, minimizing downtime and costly repairs.

Understanding the Kohler 27 HP Engine

To truly grasp how a powerful machinery system functions, it is essential to explore its various components and their interrelationships. Each part plays a crucial role in enabling the system to perform its intended tasks effectively. Understanding these individual units helps in troubleshooting issues, conducting routine maintenance, and ensuring long-term reliability.

Main Functionality of the System

The heart of any complex system is its ability to transform energy into mechanical work. The key elements responsible for this transformation work in harmony, each part performing a specific role. Understanding how they interact can significantly enhance your ability to optimize performance and prevent unnecessary breakdowns.

- Power Generation: The primary mechanism responsible for converting fuel into usable power.

- Transmission Systems: Elements that deliver the generated energy to the necessary parts for movement.

- Cooling Components: Systems designed to maintain optimal operating temperature, preventing overheating.

Importance of Regular Maintenance

One of the most effective ways to prolong the lifespan of your system is through consistent upkeep. Regular checks on the individual elements help in identifying potential wear and tear early on, allowing for timely interventions. This proactive approach reduces the likelihood of costly repairs and ensures smooth operation over time.

- Frequent Inspections: Assessing key units for any signs of malfunction.

- Cleaning Components: Keeping internal and external parts free from dirt and debris that could obstruct function.

- Lubrication: Applying the appropriate lubricants to moving parts to minimize friction.

Key Components of the Kohler Engine

Understanding the main units within a mechanical system is essential for efficient operation and troubleshooting. Each critical element serves a specific function, contributing to the overall performance and reliability. Familiarizing yourself with these core components allows for easier identification of issues and better management of the system’s upkeep.

Essential Units for Operation

The most vital parts are responsible for converting energy and ensuring that the system performs as intended. These units work together in a coordinated manner to produce the required output, each supporting a particular function in the cycle of operation.

- Fuel System: Transfers and processes fuel to provide the necessary power for functioning.

- Ignition System: Initiates combustion by creating a spark that ignites the fuel-air mixture.

- Cooling System: Prevents overheating by maintaining a stable temperature throughout the unit.

Supporting Systems and Functions

In addition to the core units, there are supporting systems that ensure smooth operation and optimal performance. These auxiliary components, though often overlooked, are just as important in maintaining the efficiency and durability of the entire setup.

- Lubrication System: Reduces friction between moving parts by distributing oil throughout the system.

- Exhaust System: Directs gases produced by combustion away from critical components, preventing buildup.

- Control Mechanisms: Regulate the operation of key systems, ensuring smooth and precise functionality.

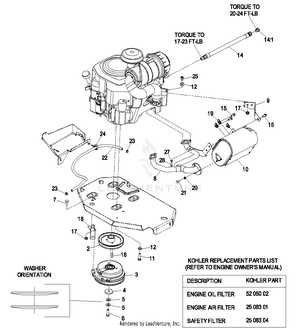

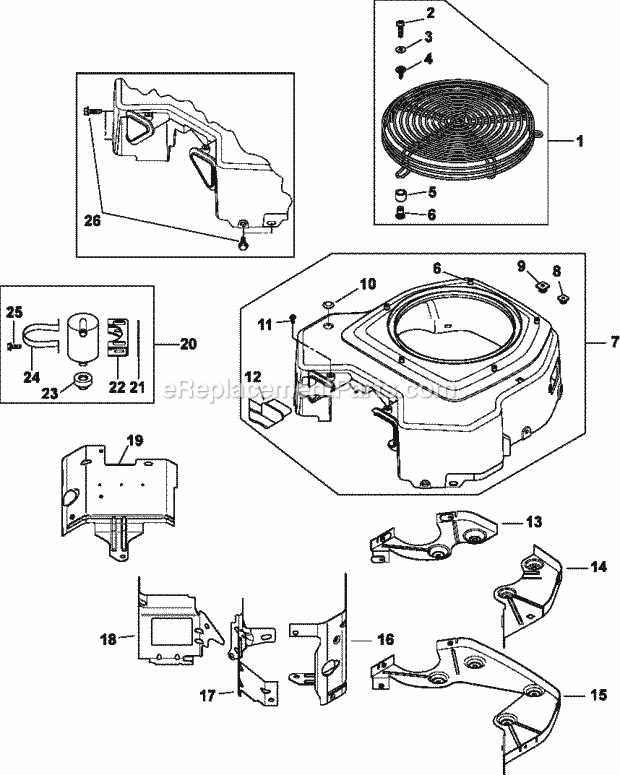

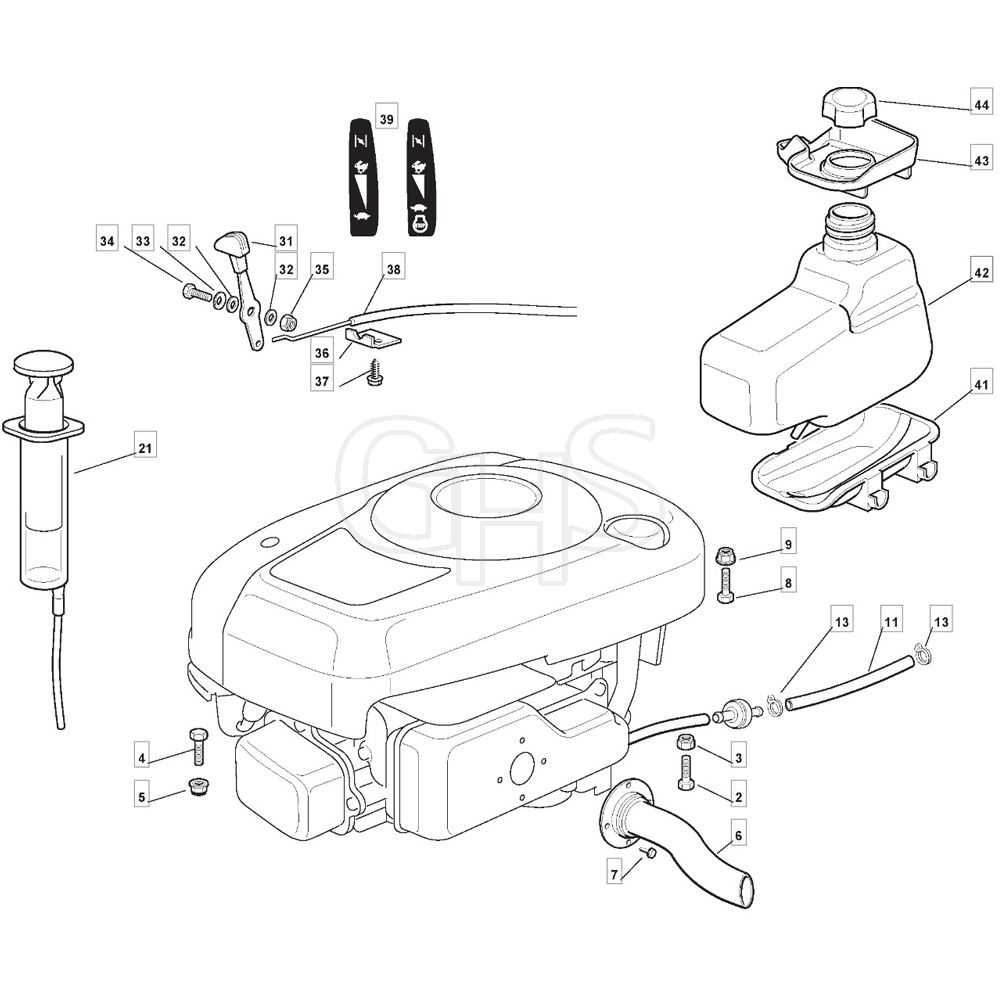

How to Read the Parts Diagram

Understanding technical illustrations is crucial when working with complex machinery. These visual guides offer a detailed look at the various elements within the system and how they are connected. Properly interpreting these drawings allows for efficient maintenance, troubleshooting, and part replacement.

To begin, it’s important to familiarize yourself with the symbols and notations used in these visuals. Different shapes and lines represent various components and their relationships. Recognizing these will help in understanding the flow of the system and pinpointing specific areas that may require attention.

- Identification of Components: Each unit or element is typically labeled with a reference number that corresponds to a detailed list for easier identification.

- Component Relationships: Lines connecting units show how they interact or transfer energy between each other, helping to map out the functionality.

- Key Features: Important features, such as mounting points or directional flow, are often highlighted with specific markings or arrows to show the correct assembly order or flow of materials.

By becoming proficient in reading these illustrations, you will be able to quickly locate any malfunctioning units and perform necessary repairs or replacements with greater precision and efficiency.

Maintenance Tips for Kohler Engines

Proper maintenance is crucial for ensuring the long-term reliability and efficiency of any mechanical system. Regular care not only prevents unexpected breakdowns but also helps to optimize performance and reduce repair costs. A proactive approach to upkeep can extend the lifespan of critical components and enhance overall functionality.

Routine Inspection and Cleaning

Keeping components clean and free of debris is a key part of any maintenance plan. Dirt, grease, and other contaminants can affect the performance of moving parts, leading to unnecessary wear. Regular inspections allow you to identify potential issues before they become major problems.

- Check for Dirt Accumulation: Clean air filters and cooling components to prevent obstruction of airflow.

- Inspect for Wear and Tear: Look for any visible signs of damage or corrosion on moving parts.

Lubrication and Fluid Checks

Keeping the system well-lubricated is vital for minimizing friction and ensuring smooth operation. Regularly checking fluid levels and applying the correct lubricants to key parts can prevent overheating and reduce the risk of damage.

- Change Fluids Regularly: Replace oils and coolants at recommended intervals to maintain optimal fluid levels and prevent buildup.

- Lubricate Moving Components: Apply appropriate lubricants to parts like shafts, gears, and bearings to reduce friction.

By following these simple maintenance tips, you can keep the system running smoothly, prevent unnecessary downtime, and avoid costly repairs in the future.

Troubleshooting Common Engine Issues

Identifying and resolving issues in a mechanical system can be a daunting task, but with a systematic approach, many common problems can be quickly diagnosed and addressed. By recognizing the symptoms of malfunctions, you can take the necessary steps to restore optimal performance, preventing further damage and costly repairs.

Engine Won’t Start

If the system fails to start, it could be due to several factors. A lack of fuel, insufficient spark, or an issue with the starting mechanism can all contribute to this problem. The following checks can help narrow down the issue:

- Fuel Supply: Ensure there is an adequate fuel supply and that the fuel is clean and free of contaminants.

- Ignition System: Check the spark plugs for wear or damage, and replace them if necessary.

- Starter Mechanism: Inspect the battery and starter motor to ensure they are functioning properly.

Overheating Issues

Overheating is a common problem, especially in systems that handle heavy workloads. This can result from inadequate cooling or blocked airflow. To address this, take the following actions:

- Check Coolant Levels: Ensure the coolant reservoir is full and free of any obstructions.

- Inspect Cooling System: Clean any dust or debris from the radiator and cooling fans to ensure proper airflow.

- Check for Leaks: Examine hoses and seals for any leaks that may cause coolant loss.

By following these steps and addressing common issues promptly, you can ensure the system remains operational and avoid extended downtime.