Having a clear understanding of the individual components of your beverage machine is essential for its proper maintenance and efficient operation. Whether you’re dealing with a malfunction or looking to optimize its performance, knowing each part’s function can help you troubleshoot and repair issues quickly. A well-maintained system ensures that your drinks are always fizzy and fresh, avoiding unnecessary delays or costly repairs.

When you are familiar with how the device is constructed, identifying the source of a problem becomes much simpler. You can quickly recognize worn-out or broken elements and replace them without professional assistance. This can save you both time and money in the long run. Furthermore, understanding the layout of the machine enables you to perform routine checks and cleaning tasks that improve its longevity.

By familiarizing yourself with the parts and their interconnections, you will be better equipped to handle any future issues, ensuring that your appliance continues to serve you for years to come. This guide will provide an overview of the key elements, how to identify them, and basic steps for maintenance. The goal is to empower you to take care of your machine and avoid common pitfalls.

Understanding the Beverage Maker Layout

Familiarizing yourself with the internal structure of your device can make a significant difference in troubleshooting and maintaining its functionality. When you know how the system is organized, it becomes easier to identify the cause of any issues and take the appropriate steps to fix them. A clear understanding of each key element in the setup helps to keep everything running smoothly.

Key Components and Their Functions

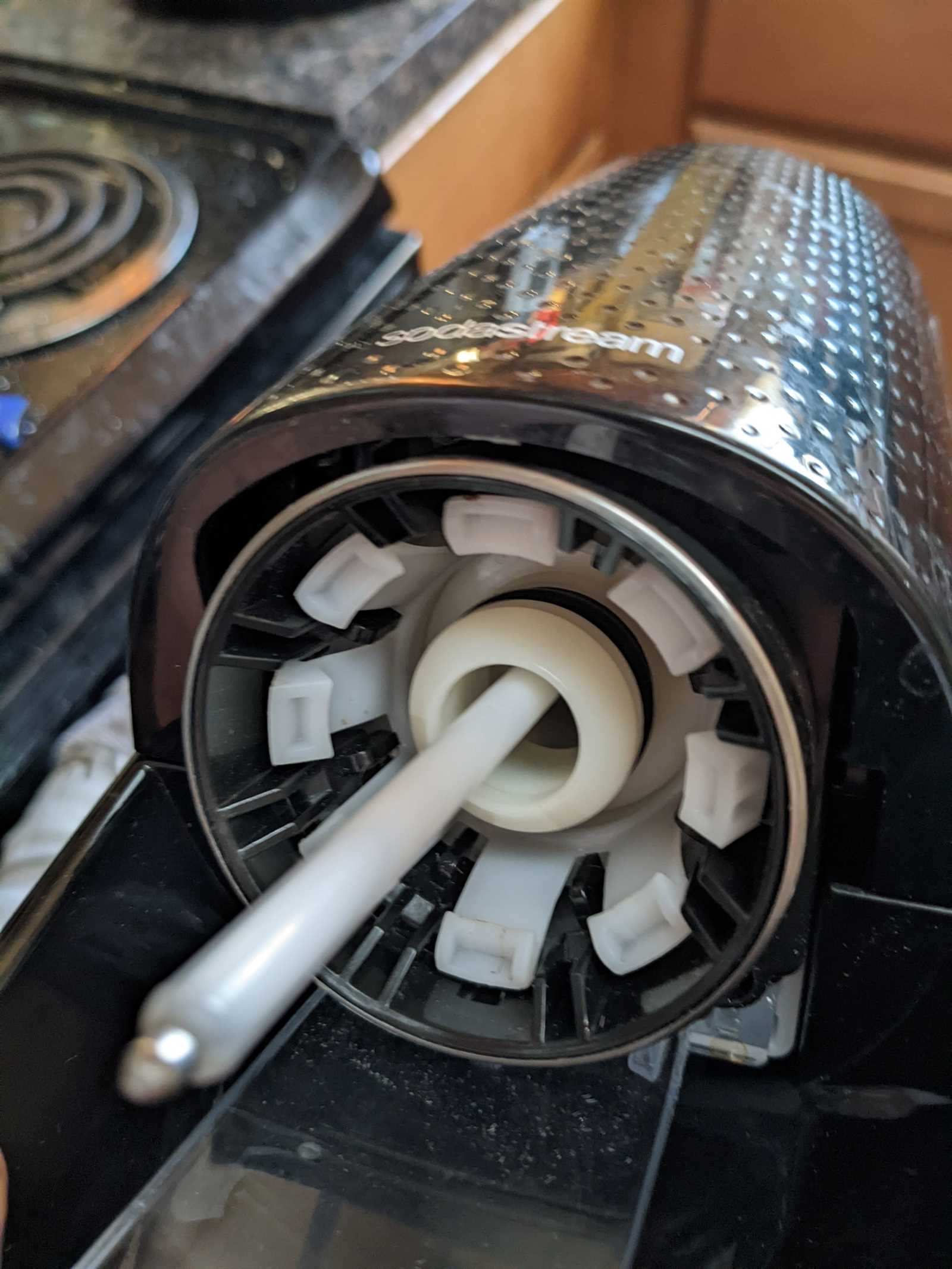

Each machine consists of several interconnected components that work together to deliver the desired results. Understanding the role of each individual part, such as the carbonation chamber or the gas regulator, is crucial for proper maintenance. Recognizing these elements allows you to spot potential problems before they escalate, keeping your appliance functioning efficiently.

Visualizing the Layout for Easier Repair

Having a visual reference of the internal structure can be incredibly helpful when performing repairs or replacements. By recognizing the layout of the system, you can quickly access and handle the necessary components, ensuring that maintenance tasks are done correctly and without unnecessary confusion. This approach minimizes the risk of damaging sensitive parts while improving the overall upkeep process.

How to Identify Key Components

Recognizing the essential elements of your beverage machine is the first step in ensuring its proper function and resolving any issues. Knowing which components are responsible for specific tasks can help you troubleshoot problems efficiently. This guide will outline how to identify the most crucial parts that affect your system’s performance.

Here are the key components to look out for:

- Gas Canister: The source of carbonation, typically a metal cylinder that contains compressed CO2 gas.

- Carbonation Chamber: Where water is infused with CO2 to create the desired fizz.

- Pressure Regulator: Controls the flow of gas into the chamber to ensure consistent carbonation levels.

- Seal and Valve: Ensures that the gas and liquid remain sealed and do not leak during the process.

- Button or Lever: Used to activate the carbonation process and adjust the level of fizziness.

By learning to identify these components, you’ll be able to recognize when something is malfunctioning. Regular inspection of these elements is vital to avoid disruptions and extend the lifespan of your appliance. When you spot any wear or tear on these parts, it’s easier to replace them and keep everything running smoothly.

Common Issues with Beverage Maker Components

Even with regular use, appliances that rely on intricate systems often encounter problems due to wear and tear or improper maintenance. Identifying these issues early can prevent further damage and ensure the machine continues to function properly. In this section, we will explore some of the most common challenges you may face and how to address them.

One of the frequent problems is leaking gas, which typically occurs when seals or valves become damaged. This can cause a loss of pressure, preventing the device from carbonating liquids properly. Another issue is insufficient carbonation, which might result from a malfunctioning pressure regulator or an empty gas canister. Both issues can lead to disappointing results and reduced efficiency.

Other common issues include clogging within the nozzle or tubing, which affects the flow of liquids, and mechanical wear on buttons or levers that trigger the carbonation process. Regular maintenance and timely part replacements can prevent these problems and extend the appliance’s lifespan. By staying vigilant and addressing minor issues as they arise, you can ensure the appliance remains in good working condition for years.

Fixing Problems with Your Machine

When issues arise with your appliance, addressing them promptly can prevent further complications and ensure continued performance. Being able to identify common problems and apply straightforward fixes is key to maintaining an efficient and reliable device. In this section, we will discuss how to handle some of the most frequent malfunctions and offer practical solutions for each.

Addressing Leaks and Low Pressure

Leaks and low pressure are two of the most common issues users face. If you notice gas escaping or a significant decrease in carbonation, check the seals and valves. Over time, these components can wear out, leading to leakage. Replacing damaged seals is usually a simple task that can restore full functionality. In some cases, a loose connection between the gas canister and the system may also be the culprit, so ensure everything is tightly secured.

Dealing with Insufficient Carbonation

If your machine isn’t providing enough fizz, the issue may lie with the pressure regulator or an empty gas canister. Start by inspecting the regulator for any signs of malfunction. If the regulator seems fine, check the gas canister to ensure it’s not depleted. If needed, replace the canister and test the system again. Additionally, clogged tubing or nozzles can sometimes hinder carbonation, so make sure all pathways are clear.

Maintaining Your Beverage System

Regular maintenance is essential for keeping your appliance in top condition and ensuring consistent performance. By following a few simple steps, you can prevent common issues and extend the lifespan of your system. Proper care not only enhances efficiency but also helps you avoid costly repairs down the road.

Start by cleaning the internal and external components regularly. Wipe down the exterior to prevent buildup, and ensure that the carbonation chamber is free from residue. It’s also important to check for any wear on key components, such as seals and valves, as these can degrade over time. Replacing these parts when necessary will keep everything working smoothly.

Additionally, make sure that the gas canister is securely connected and replaced when it runs low. Regularly inspecting the tubing and nozzles for blockages or cracks can also prevent issues that may interfere with carbonation. By staying proactive and attending to small maintenance tasks, you can enjoy a consistently high-performing system.