Maintaining your lawn equipment in optimal condition requires a clear understanding of its individual components. Whether you are a professional or a hobbyist, knowing how each part works together ensures smooth operation and extends the lifespan of your machine.

To effectively repair or replace worn-out parts, it’s essential to have a detailed reference guide. This guide breaks down each element of the machine, allowing you to identify and troubleshoot problems quickly. By following this structured approach, you can avoid unnecessary repairs and keep your equipment functioning at its best.

Proper maintenance begins with recognizing the components that make up the equipment. With the right tools and knowledge, you can address common issues without the need for professional assistance. Explore the various sections of your machine to gain a better understanding of its functionality and make informed decisions on repairs or upgrades.

Understanding the Key Components

Every piece of lawn equipment consists of several essential elements that work together to perform its tasks efficiently. Familiarity with these components allows users to operate the machinery more effectively and troubleshoot issues when they arise. From the main drive system to the cutting mechanism, each part plays a crucial role in ensuring smooth performance and durability.

One of the first steps in maintaining any equipment is identifying the main components and understanding their functions. Knowing how each part interacts with others helps in making informed decisions about repairs, replacements, or upgrades. Regular inspections are vital to ensure that all parts are working harmoniously to prevent malfunctions and extend the lifespan of the equipment.

Whether you are repairing a worn-out mechanism or replacing a faulty component, understanding the various elements of your machine ensures that maintenance tasks are completed with precision. This knowledge not only improves the machine’s functionality but also helps in preventing costly repairs and downtime.

How to Read the Components Reference Guide

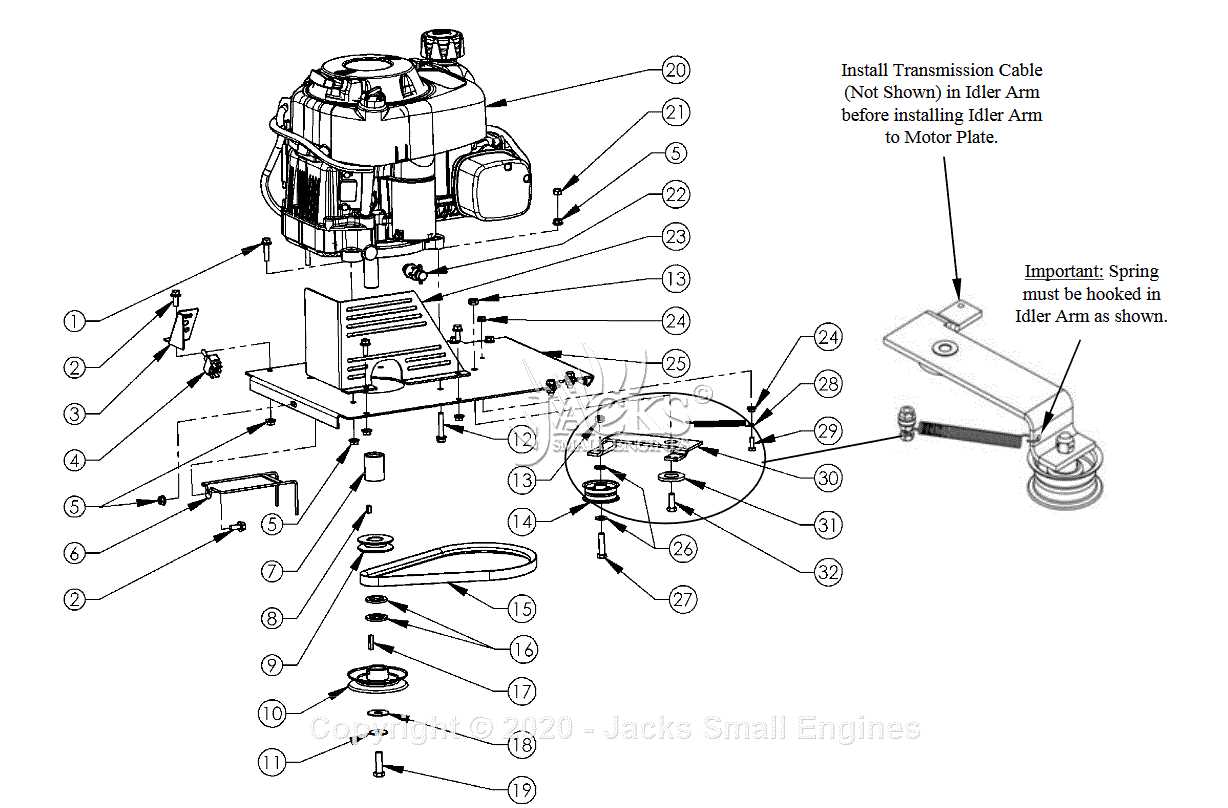

Understanding how to interpret a machine’s reference guide is a crucial skill for anyone looking to repair or maintain their equipment. This guide serves as a visual map, showing how individual elements are connected and providing essential information on their location and function. With a clear grasp of the reference, users can identify specific components that need attention or replacement.

Breaking Down the Reference Symbols

The reference guide typically uses a set of symbols and labels to represent different parts. Each symbol corresponds to a particular component, which is marked with a unique identifier for easy recognition. Familiarizing yourself with these symbols is the first step in learning how to navigate the guide effectively.

Locating and Identifying Components

Once you understand the symbols, the next step is to find the specific part you’re looking for within the guide. Typically, components are organized logically, either by function or placement within the machine. This organization helps users quickly locate the part they need and understand its role in the overall system.

Common Issues and Solutions for Lawn Equipment

Like any machinery, outdoor equipment can experience various problems over time. Recognizing these common issues and knowing how to resolve them is essential for maintaining performance and extending the lifespan of your machine. Whether it’s a malfunctioning mechanism or a wear-related issue, most problems can be traced to specific components and resolved with a few basic steps.

Frequent Mechanical Failures

Mechanical issues are often the result of worn or damaged parts that no longer function as they should. Common signs include poor performance, unusual noises, or erratic behavior during operation. Identifying the source of the problem typically requires inspecting the moving parts and ensuring everything is properly aligned and lubricated. In many cases, replacing the worn-out components can restore the equipment to optimal working condition.

Electrical Problems and Fixes

Electrical issues can also arise, especially if your machine relies on electrical systems to operate certain features. Problems like inconsistent power, failure to start, or electrical shorts can often be traced back to faulty connections or malfunctioning components. To resolve electrical issues, check the wiring for damage and ensure all connections are clean and secure. Replacing damaged cables or connectors is often the most straightforward solution to restore functionality.