Understanding the key elements of a vehicle’s suspension system is essential for maintenance and repair. These components work together to ensure smooth and safe driving performance. Familiarity with how each part functions allows for better decision-making when troubleshooting or upgrading your vehicle’s suspension.

The system’s components, arranged in a specific layout, play critical roles in absorbing shocks, maintaining wheel alignment, and supporting the overall structure. By studying the layout and function of each element, you can identify potential issues and know what to look for during inspections.

In this guide, we will explore the layout of these essential components, providing a clear overview of how each piece contributes to the vehicle’s overall efficiency. Understanding the system’s structure helps in making informed choices regarding maintenance, repairs, and replacements.

Understanding the Vehicle’s Suspension System

The suspension system plays a crucial role in supporting the weight of a vehicle, ensuring a smooth ride and proper handling. This complex structure is designed to absorb shocks from the road, maintain stability, and keep the wheels aligned for optimal performance. Each element in the system contributes to the overall function, and understanding how they work together is essential for effective maintenance and repair.

Components of the Suspension System

The suspension system consists of various components, including springs, shocks, and support beams, all of which interact to keep the vehicle balanced and responsive. Springs absorb the energy from bumps, while shocks control the rebound and ensure stability. The system also includes parts that maintain the alignment of the wheels, ensuring they stay in proper contact with the ground for better traction and control.

Why Understanding the System is Important

Knowing the structure and function of each component helps drivers identify potential issues before they become major problems. Regular inspection and maintenance of these elements are vital to prevent wear and tear that could affect performance. A well-maintained suspension system not only enhances the comfort of the ride but also improves safety and handling.

Key Components in the Suspension System

The suspension system is made up of several vital components that work together to provide stability, comfort, and safety while driving. These elements are engineered to absorb shocks, maintain alignment, and allow the vehicle to handle various road conditions efficiently. Each part plays a specific role, and understanding their functions is essential for ensuring the system operates optimally.

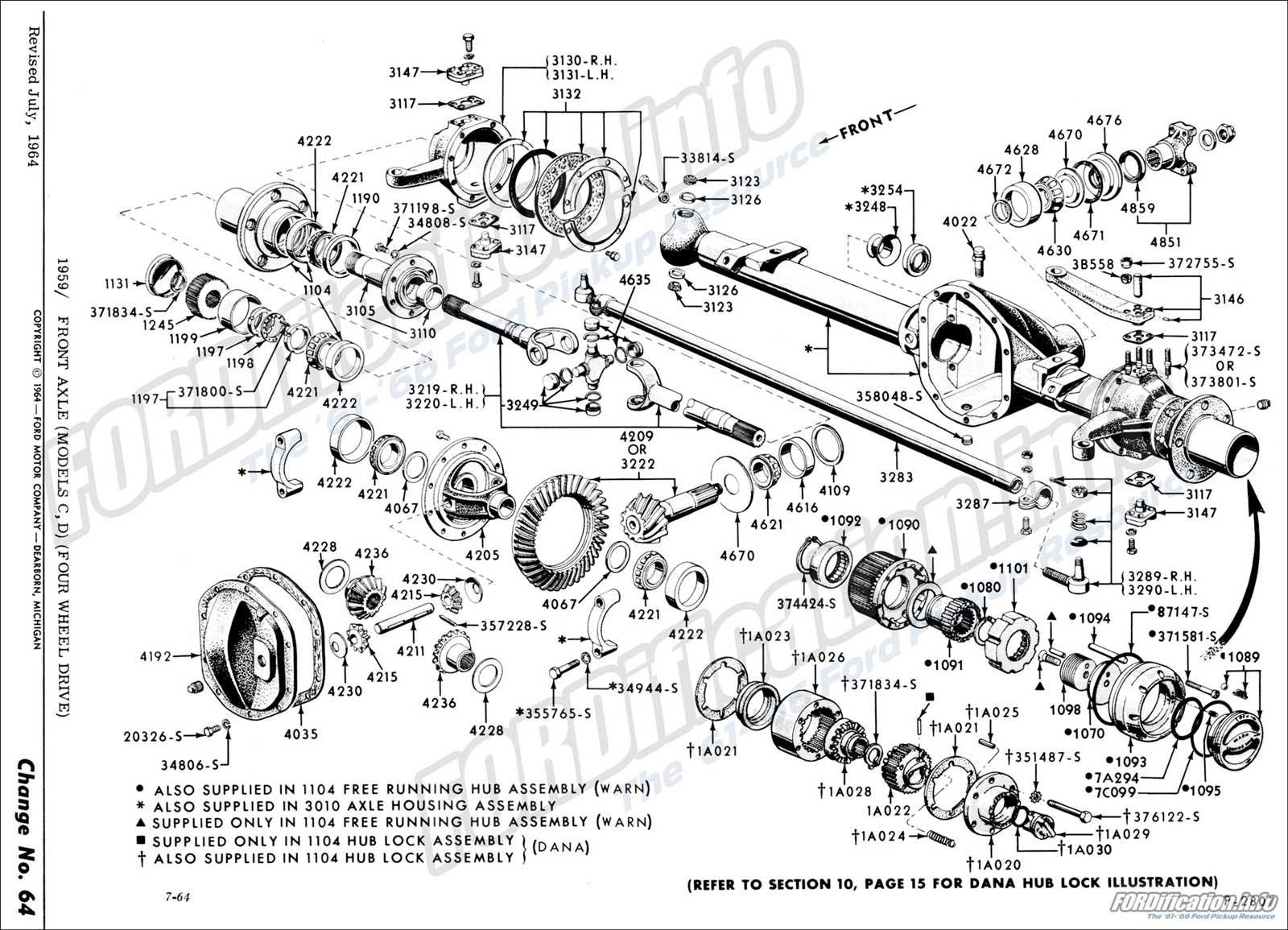

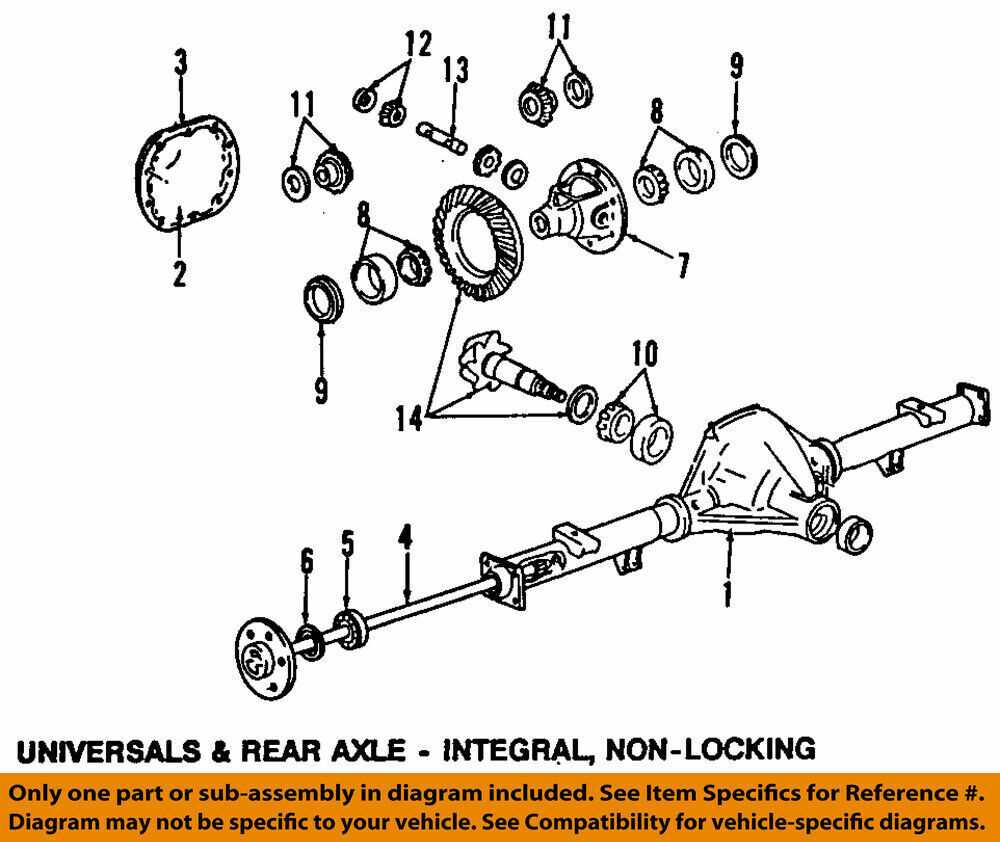

Among the core components are the springs, which are responsible for absorbing bumps and shocks from the road, and the differential, which ensures the wheels turn at the right speed when cornering. The drive shafts transfer power from the engine to the wheels, while bearings and seals help reduce friction and wear. Understanding how these pieces interact is crucial for proper maintenance and repair.

How to Read the Suspension System Layout

Interpreting the layout of a vehicle’s suspension system is an essential skill for anyone involved in maintenance or repair. A well-organized schematic provides a visual guide to the components, helping users understand their relationships and individual functions. Familiarizing yourself with the symbols, labels, and structure used in these diagrams can make the process much clearer and more efficient.

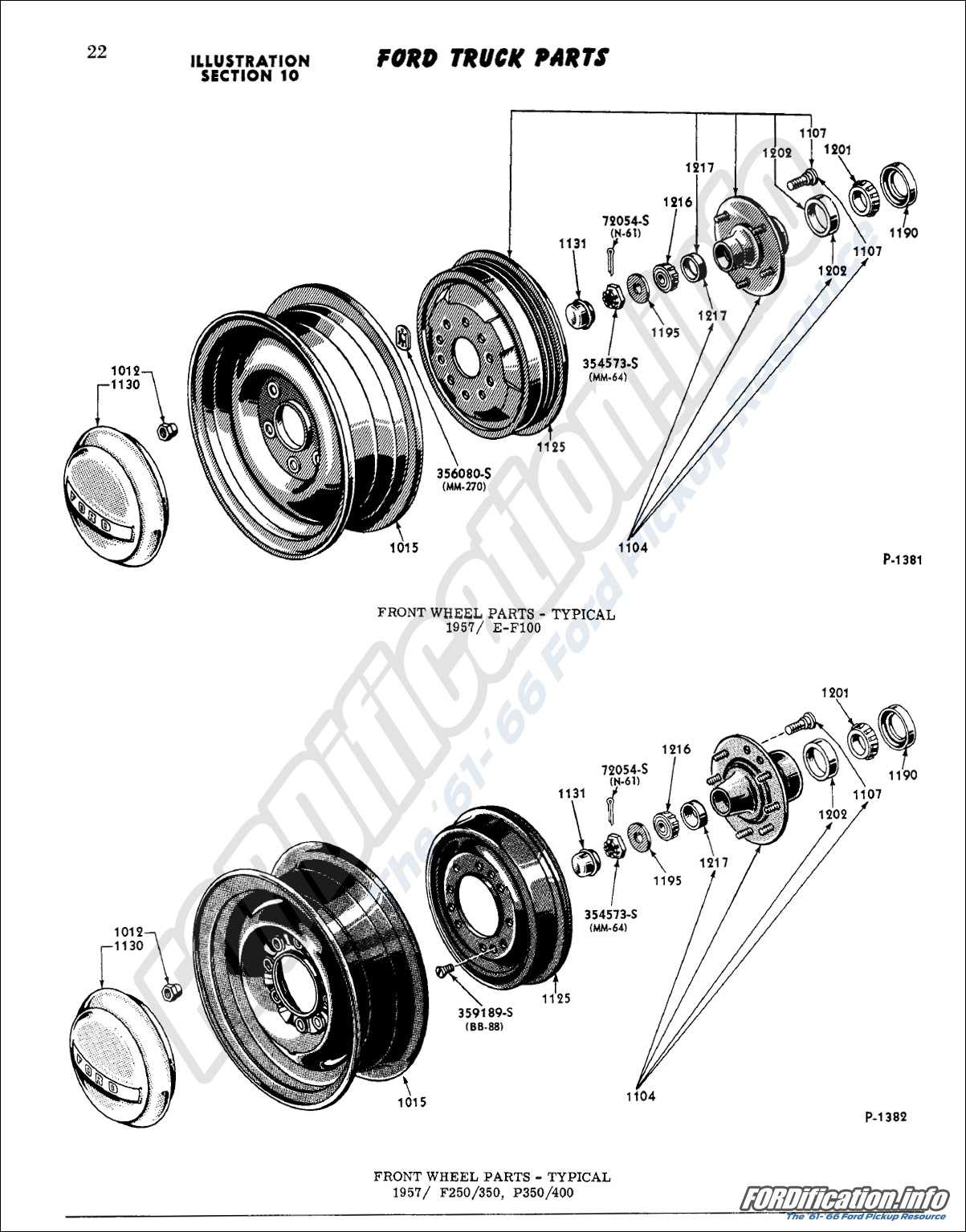

Understanding Symbols and Labels

Most schematics use specific symbols to represent different parts of the system. These symbols are often accompanied by labels that indicate the part numbers, sizes, and material specifications. It’s important to learn what each symbol represents to avoid confusion when interpreting the diagram. Some layouts also provide reference numbers that correspond to specific components in the vehicle.

Interpreting Connections and Relationships

In addition to individual components, the layout also shows how various parts are connected. Understanding these connections is crucial for diagnosing issues, as it reveals how parts interact with each other. Pay attention to lines that indicate movement or force transfer, as these are key to understanding the system’s operation and identifying potential areas of wear or failure.