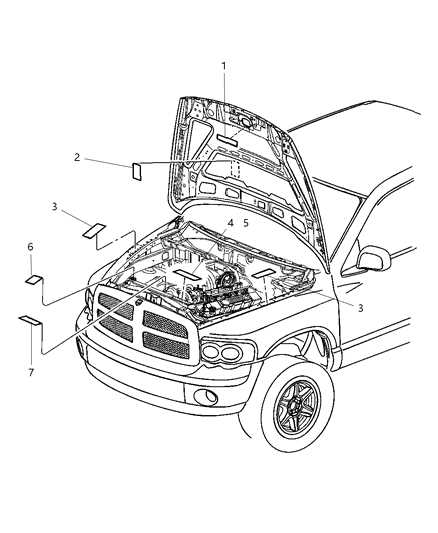

When maintaining or repairing a vehicle, understanding the internal system and its various components is crucial. A clear visual representation of these parts can provide valuable insights into their placement and function. Knowing how each piece contributes to the overall performance can simplify troubleshooting and enhance maintenance efforts.

The complex system of a motorized vehicle includes numerous elements that work together to ensure smooth operation. From the power source to auxiliary units, each part plays a role in generating power, regulating processes, and ensuring efficiency. Familiarity with these components can help identify potential issues and facilitate timely repairs.

In this section, we will explore the layout and organization of critical elements within a mechanical system, offering a comprehensive view that aids in both understanding and servicing. Recognizing each part’s function allows for better decision-making when performing diagnostics or upgrades. Whether you’re a seasoned technician or a novice enthusiast, having this knowledge is essential for effective vehicle care.

Understanding Vehicle Powertrain Components

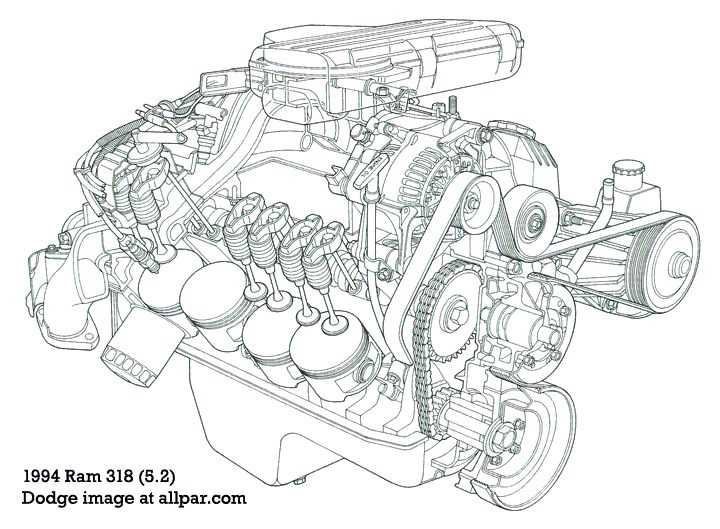

Within any mechanical system, various elements come together to create a functional unit. Each component is designed to work harmoniously with others to generate, manage, and distribute power efficiently. Having a solid grasp of these interconnected elements is key to maintaining performance and identifying issues when they arise.

The primary function of the power-generating system is to ensure that all moving parts operate in unison, while additional mechanisms support their efficiency. These elements vary in size and shape, from the smaller, intricate parts to the larger, more robust pieces that take on significant operational roles. Understanding the specific task each element performs allows for a deeper understanding of how the entire system functions.

By exploring the arrangement and functions of each crucial element, one can gain a clearer picture of the system’s structure. This knowledge is valuable not only for routine maintenance but also for troubleshooting issues that may arise, ensuring optimal performance in the long term.

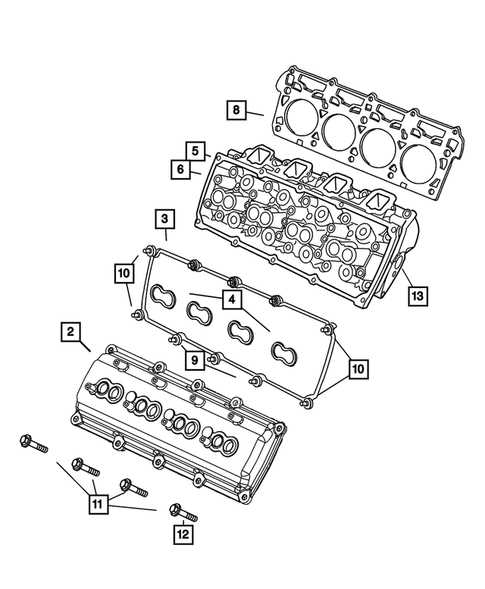

Detailed Breakdown of Engine Components

To fully understand how a mechanical system operates, it’s essential to examine the key elements that contribute to its function. Each part plays a unique role, working in concert with others to deliver the desired performance. Identifying these components and their respective functions allows for a clearer comprehension of how they work together.

The core components within the power generation system include those responsible for initiating movement, controlling fluid flow, and managing combustion. Each element is strategically placed to ensure seamless interaction, and each has a specific task that directly impacts the overall efficiency and functionality of the system.

By breaking down the essential components, it’s easier to identify potential problem areas. Whether focusing on the parts that handle fuel delivery, air intake, or exhaust systems, understanding their relationship and individual purpose helps in troubleshooting and ensuring everything operates smoothly.

Common Issues with Vehicle Power Systems

Every mechanical system is subject to wear and tear over time, and common issues can arise that affect performance. Identifying these problems early on is crucial for preventing further damage and ensuring smooth operation. Understanding the typical challenges that may occur can help vehicle owners and technicians address them effectively.

Some of the most frequent problems in a powertrain system include:

- Oil Leaks: Leaks can occur at various points, often from gaskets or seals, leading to potential damage if not addressed promptly.

- Overheating: Issues with the cooling system or improper fluid circulation can cause the system to overheat, reducing overall performance.

- Misfires: Irregular combustion or fuel delivery issues may lead to poor engine performance, causing misfires and reduced efficiency.

- Electrical Failures: Faulty wiring or sensor malfunctions can disrupt critical systems, affecting ignition and operation.

Addressing these problems early can prevent more costly repairs down the line. Regular maintenance checks and timely diagnostics play a vital role in identifying and solving these common issues.

How to Identify Faulty Components

Detecting malfunctioning components within a mechanical system is essential to maintaining optimal performance. Various signs and symptoms may indicate that a part is not functioning correctly. Being able to recognize these warning signs early can prevent further damage and costly repairs.

Common symptoms of faulty components include:

- Unusual Noises: Grinding, knocking, or whining sounds may signal worn or damaged parts, such as bearings or belts.

- Loss of Power: If the system is not delivering expected performance, it could be due to a malfunctioning component, like a fuel injector or spark plug.

- Leaks: Fluid leaks around the system can indicate faulty seals, gaskets, or hoses that need attention.

- Excessive Vibration: Unusual shaking or vibrations during operation may be caused by an imbalance in key parts or damaged mounts.

If you notice any of these symptoms, a thorough inspection is necessary. By carefully examining individual components and understanding their functions, you can identify potential issues and take corrective action before they escalate.

Maintaining Your Vehicle Power System

Regular upkeep is crucial for keeping any mechanical system running efficiently. Proper maintenance ensures longevity, reduces the risk of failure, and helps preserve the performance of key components. By adhering to routine checks and preventive measures, you can avoid costly repairs and maintain peak functionality.

Essential Maintenance Tasks

To keep the power generation system in top condition, it’s essential to follow a few basic maintenance steps:

- Oil Changes: Regularly changing the fluid ensures that all moving parts remain lubricated and operate smoothly.

- Cooling System Check: Inspecting hoses, coolant levels, and the radiator prevents overheating and ensures the system stays within optimal temperature ranges.

- Air Filter Replacement: A clean air filter promotes efficient combustion and prevents debris from entering the system.

Monitoring Key Components

In addition to routine maintenance, it’s important to stay vigilant for any signs of wear or issues that may develop over time:

- Check for Leaks: Look for any fluid leaks around the system, especially near seals or hoses.

- Listen for Unusual Noises: Uncommon sounds like grinding or knocking may indicate that something is out of place.

By staying proactive with maintenance, you can ensure that the system operates at its best for years to come.