When it comes to maintaining your lawn equipment, knowing how each part functions is essential for ensuring smooth operation and longevity. This guide offers a comprehensive look at the essential elements of your machine and how they work together.

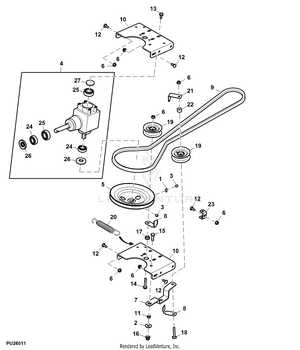

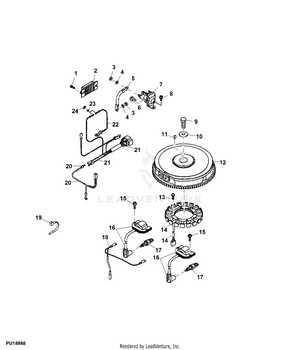

Accurate identification of each component is key when troubleshooting or performing maintenance tasks. A clear visual representation can significantly ease the process of repairs and replacements, saving both time and effort.

By understanding the layout and functions of each section, you’ll be better equipped to perform routine checks, identify potential issues early, and keep your machinery running at its best. With the right knowledge, keeping your equipment in top condition becomes a straightforward task.

Understanding the Key Components of Your Lawn Equipment

Knowing the fundamental elements of your lawn tractor is essential for effective maintenance and repair. Each part has a specific role that contributes to the overall performance of the machine. By understanding how they interact, you can ensure the proper functioning of your equipment.

The various sections of the machine include both mechanical and electrical components, each designed for specific tasks such as power transmission, steering, and control. Recognizing these components allows for more efficient troubleshooting and helps you address potential issues before they become significant problems.

Familiarity with the internal structure and layout of your equipment provides valuable insight into how the system works. This knowledge helps when making decisions about repairs, replacements, and maintenance schedules to keep your machine running smoothly and efficiently.

Key Components in the Equipment Layout

Understanding the key elements of your machine is crucial for proper maintenance and efficient troubleshooting. Each part plays a specific role in ensuring the overall functionality of the equipment. Below, we will explore the essential sections and their functions to give you a better idea of how the system operates.

Mechanical Components

- Engine: The heart of the machine, responsible for generating the power needed for all functions.

- Transmission: Transfers power from the engine to the wheels, allowing movement and speed control.

- Steering System: Ensures precise maneuvering and control of the machine during operation.

Supportive and Auxiliary Parts

- Fuel System: Stores and delivers fuel to the engine, ensuring smooth operation.

- Cooling System: Prevents the engine from overheating by regulating temperature levels.

- Electrical Components: Powers various systems, including lights, sensors, and safety features.

Each component works together in harmony to provide reliable performance. Recognizing their functions and understanding how they interconnect can significantly improve the maintenance process and prevent unnecessary breakdowns.

How to Use the Component Layout

Using a visual representation of your machine’s structure is a valuable tool for identifying parts and understanding their placement. This guide will help you navigate the layout effectively, allowing you to pinpoint components quickly and accurately for maintenance or repairs.

Step 1: Begin by reviewing the overall layout. Look for clear labels and sections that group related components together. Understanding these categories will help you narrow down where each part is located.

Step 2: Identify the parts that require attention or replacement. If you are troubleshooting an issue, focus on the specific system (such as the transmission or steering) to locate the components that might be causing the problem.

Step 3: Use the layout as a reference during disassembly and reassembly. The detailed visuals provide a clear guide, ensuring that parts are correctly installed or replaced without confusion.

By utilizing this visual guide, you can enhance your maintenance routine, reduce downtime, and improve the overall performance of your machine.

Step-by-Step Guide for Identification

Identifying components within your equipment is essential for efficient maintenance and repair. By following a systematic approach, you can easily recognize and assess each part to determine if any require attention or replacement.

Step 1: Begin by reviewing the general layout of the machine. Familiarize yourself with the major sections, such as the engine, transmission, and steering system. These are often the primary areas where issues may arise.

Step 2: Narrow down the specific area you need to inspect. Whether you’re addressing a mechanical malfunction or a simple maintenance task, focusing on one system at a time helps avoid confusion and ensures accuracy.

Step 3: Cross-reference the component you’ve located with the layout to confirm its correct identification. Pay close attention to unique features such as size, shape, or labeling to ensure you’ve pinpointed the right part.

Step 4: Once identified, check for any signs of wear or damage. If any parts appear worn or faulty, make note of them for replacement or further inspection.

By following these steps, you can quickly and accurately identify the components in your machine, facilitating smoother maintenance and minimizing downtime.

Maintenance Tips for Your Lawn Equipment

Proper maintenance is essential for keeping your machine running efficiently and extending its lifespan. By regularly inspecting and servicing key components, you can prevent breakdowns and ensure that your equipment performs at its best.

Regular Cleaning and Inspections

One of the most important maintenance tasks is keeping your equipment clean. Regularly remove dirt, grass, and debris from both the exterior and under the hood. This prevents the build-up of materials that can affect performance and cause overheating.

Additionally, inspect the components periodically. Check for wear on belts, blades, and other critical parts. Early detection of damage can help avoid costly repairs and downtime.

Lubrication and Fluid Checks

Ensure that all moving parts are properly lubricated to reduce friction and wear. Regularly check the oil, coolant, and fuel systems, as these play a significant role in the overall performance of the machine. Clean or replace filters as needed to maintain efficiency.

By following these simple maintenance tips, you can keep your equipment in excellent working condition for years to come. Regular upkeep ensures that you’ll avoid major repairs and enjoy optimal performance every time you use it.