In every engine, efficient airflow management is crucial for optimal performance. Various components work together to regulate the intake of air, influencing fuel combustion and overall efficiency. This system ensures that the right amount of air enters the engine at the right time, contributing to smooth acceleration and stable operation.

Components play a significant role in this system, as each one serves a specific function in directing and managing airflow. From controlling the volume of air entering the combustion chamber to ensuring smooth transitions between different engine speeds, these components are essential to the engine’s responsiveness.

Understanding the structure and function of each element within the system is fundamental to diagnosing issues, performing maintenance, and enhancing engine performance. This section will break down the key components and their roles in maintaining optimal airflow control, helping to improve engine efficiency and longevity.

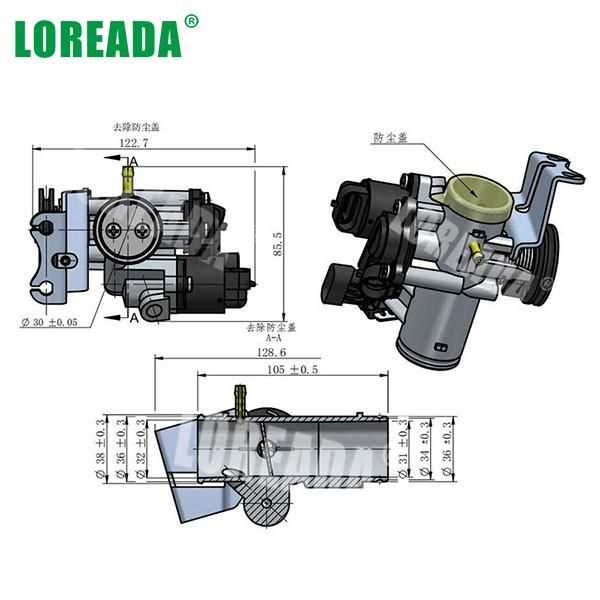

Understanding the Throttle Body Structure

In modern engines, the system that controls airflow is essential for achieving a balanced fuel mixture and efficient combustion. Several components work together in harmony to regulate the amount of air entering the engine, ensuring optimal performance across various driving conditions. The structure of this system is designed to handle different engine demands, adapting airflow as necessary.

Key Elements of Airflow Control

The main elements in this system are designed to allow precise control of air intake. These elements work in conjunction with sensors and valves to adjust airflow based on factors such as engine speed, load, and temperature. Each component serves a specific role, contributing to smooth and efficient engine operation.

Functionality and Adaptability

This system is adaptable to changing driving conditions, ensuring that the right amount of air is supplied at the right time. It is particularly important during acceleration and deceleration, where airflow needs to be adjusted quickly to match the engine’s demands. Properly functioning components ensure that the engine runs smoothly and efficiently across a variety of situations.

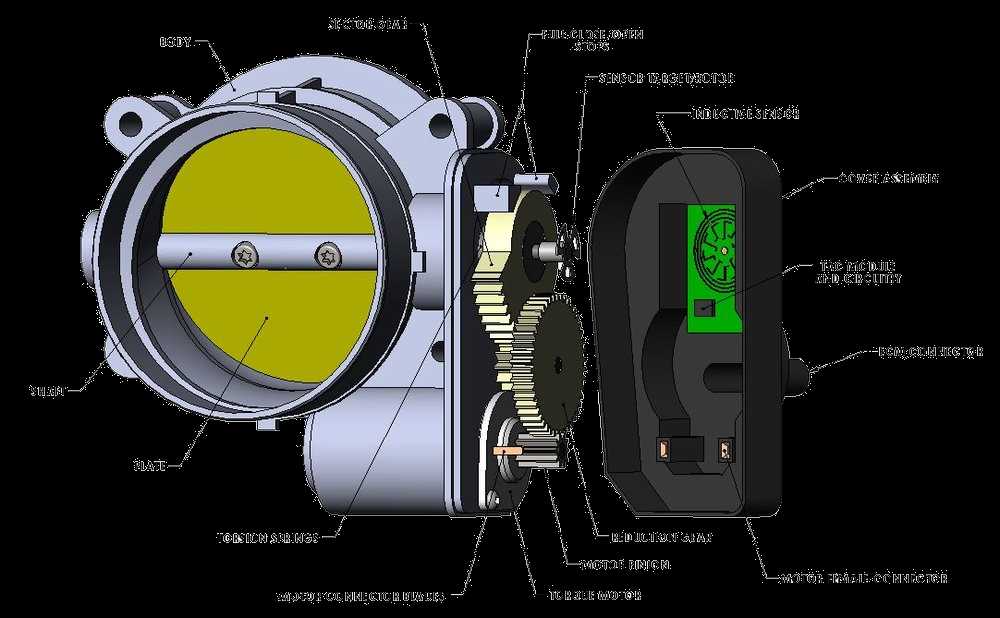

Key Components of Throttle Body Assembly

The system responsible for controlling airflow into the engine consists of several crucial elements. These components work together to ensure that air is delivered efficiently to the engine, allowing it to perform optimally. Each element plays a specific role in maintaining a smooth operation, responding to changes in engine speed, load, and temperature.

Air Intake Valve

The air intake valve is a critical component in managing the flow of air into the engine. It opens and closes depending on the engine’s demand for air, adjusting based on factors like acceleration and deceleration. A properly functioning valve ensures that the right amount of air enters the combustion chamber, contributing to balanced fuel combustion and engine efficiency.

Sensor Mechanism

Sensors within this system monitor the air intake and provide feedback to the engine control unit (ECU). This data helps the ECU adjust fuel delivery and maintain optimal engine performance. Accurate sensor readings are vital for maintaining the correct air-to-fuel ratio, especially during rapid changes in engine speed.

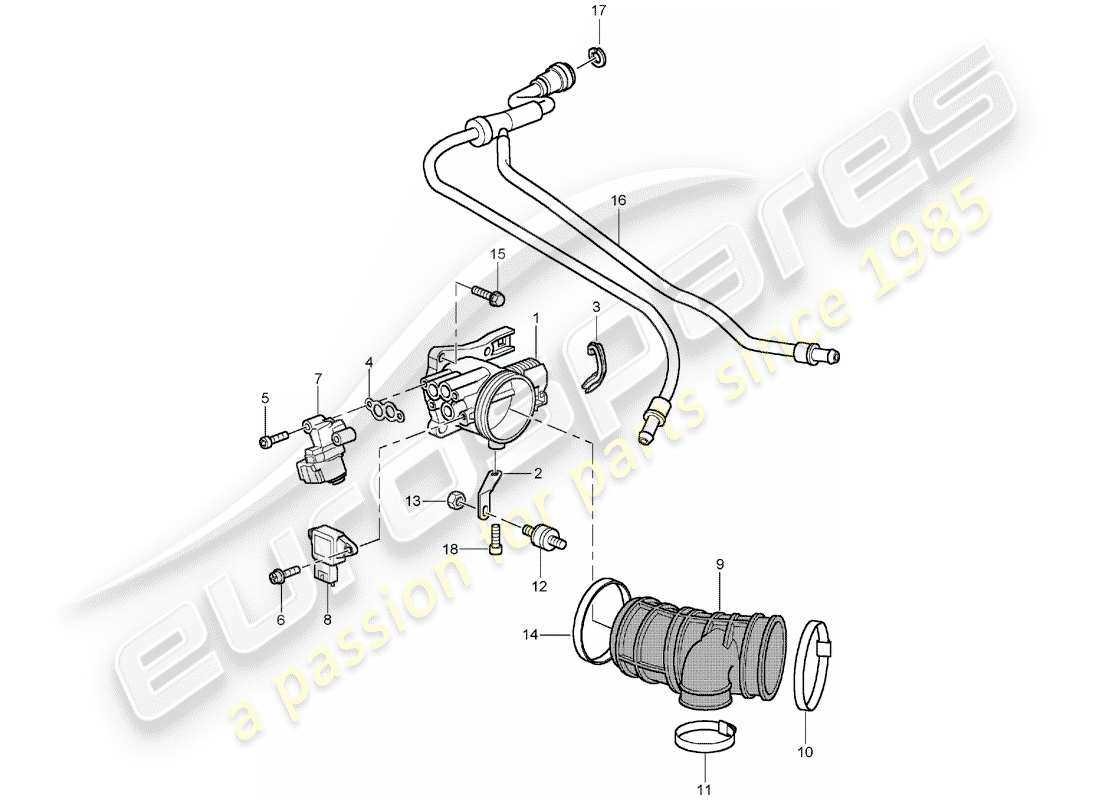

How Throttle Body Affects Engine Performance

The system controlling air intake plays a pivotal role in engine efficiency and responsiveness. By regulating the volume of air entering the engine, this system helps achieve the optimal air-to-fuel ratio, which directly influences overall performance. Proper airflow management ensures smooth acceleration, improved fuel efficiency, and reduced emissions.

Several factors impact engine performance, all of which depend on how well this mechanism functions:

- Airflow Control: The system adjusts the amount of air entering based on engine demand, ensuring that the right balance is maintained.

- Acceleration Response: Smooth transitions during acceleration are possible due to precise airflow adjustments, preventing engine hesitation.

- Fuel Efficiency: Maintaining the correct ratio of air and fuel enhances combustion, reducing waste and improving fuel economy.

- Emissions Control: Proper airflow ensures efficient combustion, leading to fewer harmful emissions released into the environment.

When this system is properly calibrated, it allows the engine to perform at its best, whether at low speeds or under heavy load. However, any malfunction or inefficiency can result in poor engine response, increased fuel consumption, and higher emissions. Therefore, maintaining this system is essential for optimal engine health and performance.