Proper maintenance of your equipment is essential for its longevity and performance. Understanding the structure and functionality of each individual part is key to troubleshooting and ensuring everything operates smoothly. A detailed breakdown of components can save time, reduce repair costs, and help you identify potential issues before they become significant problems.

Familiarizing yourself with the various elements of your machinery allows you to spot wear and tear early on. It also makes it easier to replace or repair specific parts when necessary. By having a clear understanding of how each part fits into the whole system, you can perform maintenance more efficiently and accurately.

Whether you’re looking to fix a malfunction or simply improve the efficiency of your equipment, knowing its internal structure is a crucial first step. This section will guide you through the important elements and help you gain the insight needed to keep your machinery in optimal working condition.

Understanding the Equipment Components

To ensure smooth operation and longevity of your machinery, it’s essential to comprehend the various components that make up the entire system. Each individual part plays a unique role, contributing to the overall efficiency and functionality. Gaining a deeper understanding of these elements allows for more effective troubleshooting and maintenance.

Key Functional Elements

Every piece of equipment contains vital parts that contribute to its overall performance. From the power system to the operational controls, each element is carefully designed to work together. Recognizing how each component interacts with others is crucial for maintaining a smooth workflow and identifying issues early.

Maintenance and Repairs

By familiarizing yourself with the key components, you’ll be better equipped to handle maintenance tasks. Understanding the location and function of each part simplifies the process of repairs or replacements. Proper care ensures that your machinery runs optimally and lasts for many years to come.

How to Read the Equipment Breakdown

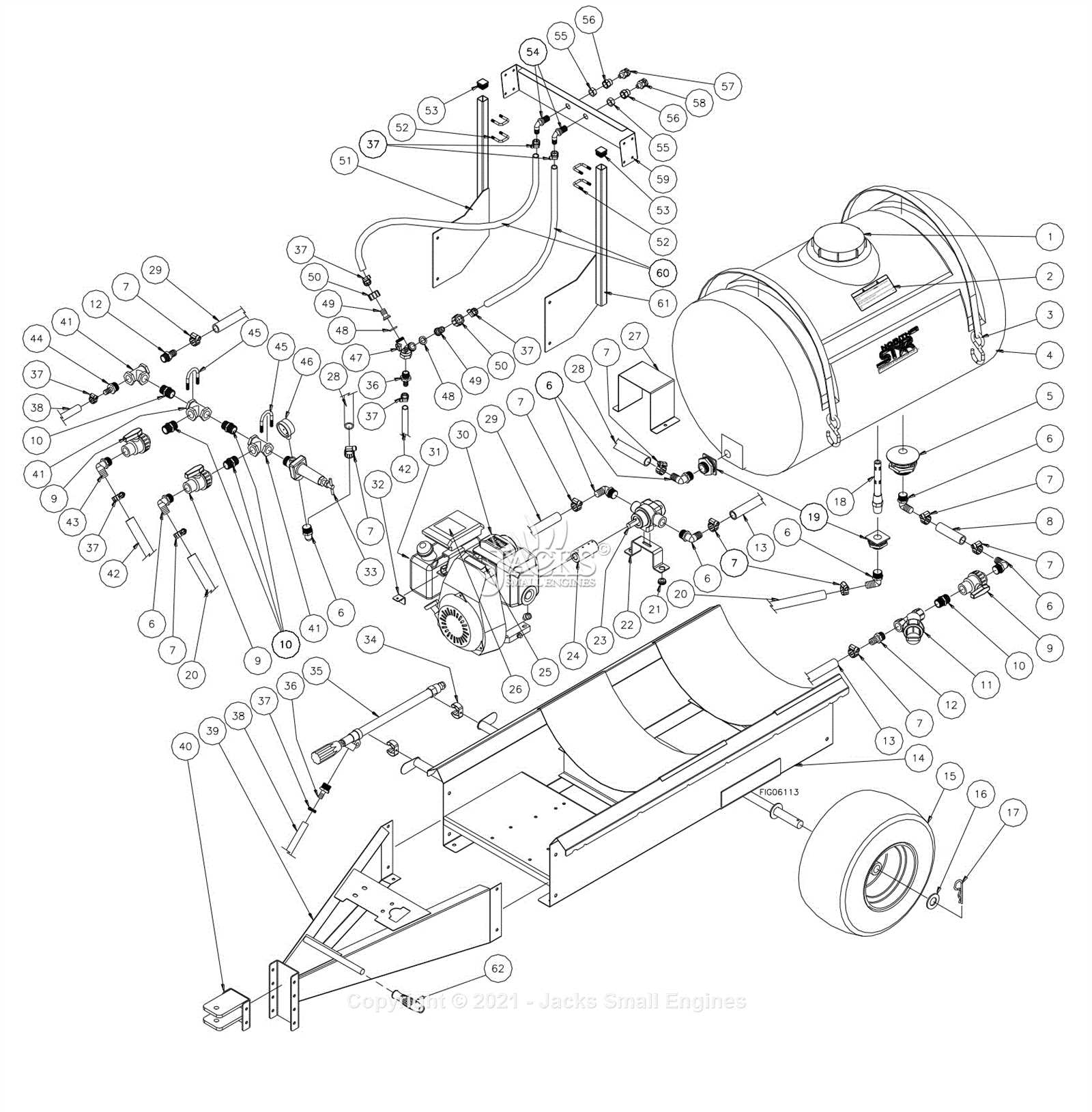

Understanding how to interpret the breakdown of your equipment’s components is vital for performing accurate repairs and maintenance. A clear visual representation allows you to easily identify each element and its connection within the system. Knowing how to read this type of reference guide helps in diagnosing issues and locating specific components quickly.

Start by familiarizing yourself with the labels and symbols used within the visual guide. These indicators provide information about the function and position of each part. Some parts may be grouped together to highlight specific sections of the machine, which can further assist in troubleshooting by isolating areas that need attention.

Once you are comfortable with the structure and terminology, you can use the breakdown to locate and assess individual components. This will also help you determine which parts need replacement or repair, making the process more efficient and less time-consuming.

Maintaining Your Equipment Effectively

Regular upkeep of your machinery is essential for optimal performance and longevity. Consistent care helps prevent costly repairs and ensures that all components function properly. By following a few simple maintenance steps, you can extend the life of your equipment and avoid unexpected breakdowns.

- Inspect Components Regularly: Check for signs of wear, corrosion, or damage. Early detection can prevent major failures.

- Clean the Equipment Thoroughly: Keep all surfaces free from dirt, debris, and buildup. This helps maintain smooth operation and prevents clogging.

- Lubricate Moving Parts: Ensure that moving components are well-lubricated to avoid friction and wear. Follow the manufacturer’s recommendations for the best lubrication practices.

- Replace Worn or Damaged Parts: If any part is showing signs of damage, replace it promptly to maintain efficiency and avoid further issues.

By staying on top of these tasks, you can ensure that your equipment continues to perform at its best, reducing downtime and enhancing productivity.