When maintaining and repairing farming machinery, it is crucial to have a clear understanding of its internal structure. Knowing how each element functions and interacts with others ensures efficient operation and longevity. The right approach to handling these complex systems can significantly improve the performance of your equipment.

Visual references and technical schematics are invaluable tools in this process. They help identify key components and provide guidance on how to properly maintain or replace worn-out parts. By interpreting these guides, you can avoid common mistakes and enhance the overall effectiveness of your machinery.

Regular inspection and care are essential for maximizing the lifespan of agricultural equipment. Routine maintenance not only prevents costly repairs but also ensures that every part is functioning optimally. Having a solid understanding of the internal mechanics allows for timely interventions, keeping your machinery in top condition.

Understanding the Agricultural Machinery Components

Farming machinery is a complex system where each element plays a vital role in its operation. Recognizing how different components work together is essential for proper maintenance and repair. A deeper understanding of these parts can lead to more efficient troubleshooting and ensure smooth operation throughout the harvesting season.

Each piece of equipment features various essential parts, each with a specific function. From the feeding mechanism to the cutting system, every element must perform correctly for the machine to operate at peak performance. Knowing where to locate and how to repair or replace malfunctioning components can save both time and resources.

- Drive system: Transfers power throughout the machine to operate the various mechanisms.

- Feeding mechanism: Ensures material is efficiently fed into the machinery for processing.

- Cutting system: Handles the cutting or compressing of material depending on the model.

- Wrapping mechanism: Handles the final stage of processing, such as bundling or wrapping material.

Understanding these main sections will help you troubleshoot effectively and perform the necessary repairs when needed. Recognizing the connection between these components and their functions ensures that you can operate the equipment safely and efficiently, reducing downtime and improving productivity.

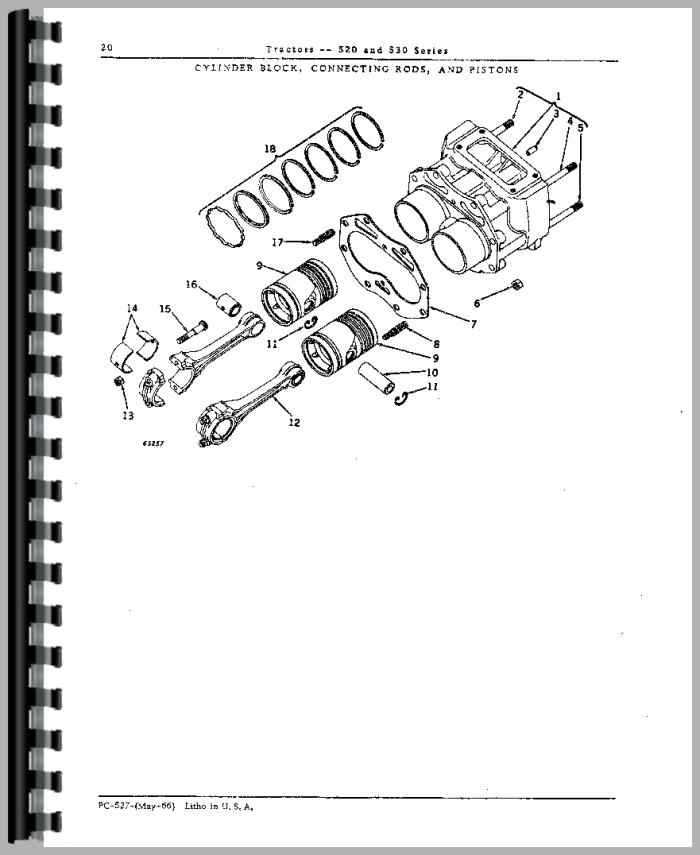

How to Identify Key Parts in the Diagram

Understanding a machine’s technical layout is essential for performing accurate repairs and maintenance. A detailed representation of the internal components offers valuable insights into how each part contributes to the machine’s overall function. By carefully studying these visual guides, you can easily locate specific elements and understand their roles in the machinery.

Start by familiarizing yourself with the general structure of the system. Focus on the larger components first, as these typically play critical roles in the machine’s operation. Once you have a basic understanding, you can narrow down to smaller components that assist in more specialized functions. Pay attention to the connections between parts, as this will help you identify their interdependence.

Take note of any labels or markings that indicate specific parts or their functions. These visual cues are often included to guide users through the maintenance or assembly process. With careful attention to detail, you will be able to pinpoint the exact components that need attention, ensuring a smoother repair process and more efficient machine performance.

Common Maintenance Tips for Agricultural Equipment

Proper care and attention to machinery ensure optimal performance and extend its operational lifespan. Regular upkeep helps avoid costly repairs and downtime, allowing your equipment to function efficiently throughout the working season. A routine maintenance schedule that includes inspection, lubrication, and cleaning can prevent many common issues before they arise.

Start by checking the major components of the system for wear and tear. Inspect belts, chains, and other moving parts for any signs of damage or looseness. Tighten connections and replace any parts that show significant signs of wear. Keeping these elements in top condition ensures smooth and reliable operation.

Lubrication is another key aspect of maintaining agricultural machinery. Regularly apply the recommended lubricants to moving parts to reduce friction and wear. Over time, even small amounts of friction can cause parts to wear out prematurely, so it’s crucial to keep everything well-lubricated.

Finally, cleaning is often overlooked but is essential for preventing debris buildup. Remove dirt, dust, and other residues from the equipment after each use. This prevents blockages and keeps components functioning properly. Taking the time for routine maintenance will not only enhance performance but also improve the overall lifespan of your machinery.