Maintaining outdoor machinery is crucial for ensuring optimal performance and longevity. Understanding the various components of your lawn tool and how they work together can make repairs and upkeep significantly easier. By learning the specific elements involved, you can avoid common issues and address problems quickly when they arise.

In this guide, we will break down the key elements of your equipment, offering a detailed look at the structure and function of each part. From simple wear and tear to more complex malfunctions, knowing the layout and connections will help you troubleshoot with confidence.

Whether you are a beginner or a seasoned user, this information will prove valuable in extending the life of your machine. By familiarizing yourself with the intricate details of each mechanism, you can ensure your equipment runs smoothly for years to come.

Understanding Lawn Equipment Components

When it comes to maintaining your lawn tool, it is essential to familiarize yourself with its key components. Each part plays a vital role in ensuring smooth operation and effective performance. A clear understanding of how these elements fit together will not only make maintenance easier but also help identify issues early on. Knowing how each piece functions enables you to perform timely repairs, extending the life of your equipment.

Key Components and Their Functions

Every machine has a variety of interconnected elements, each contributing to its overall functionality. The main parts that come into play include cutting blades, the pulley system, and the frame. These pieces work in unison to provide the necessary force and control for effective grass trimming. A well-maintained structure ensures that each component operates efficiently, minimizing wear and tear.

Signs of Wear and When to Replace

Like any piece of machinery, certain parts will eventually wear out over time. Understanding the signs of wear and knowing when to replace key elements can prevent costly breakdowns. For example, blades should be checked regularly for signs of dullness or damage, while other parts like belts and pulleys might need to be replaced if they start showing cracks or signs of fraying.

How to Read a Lawn Equipment Layout

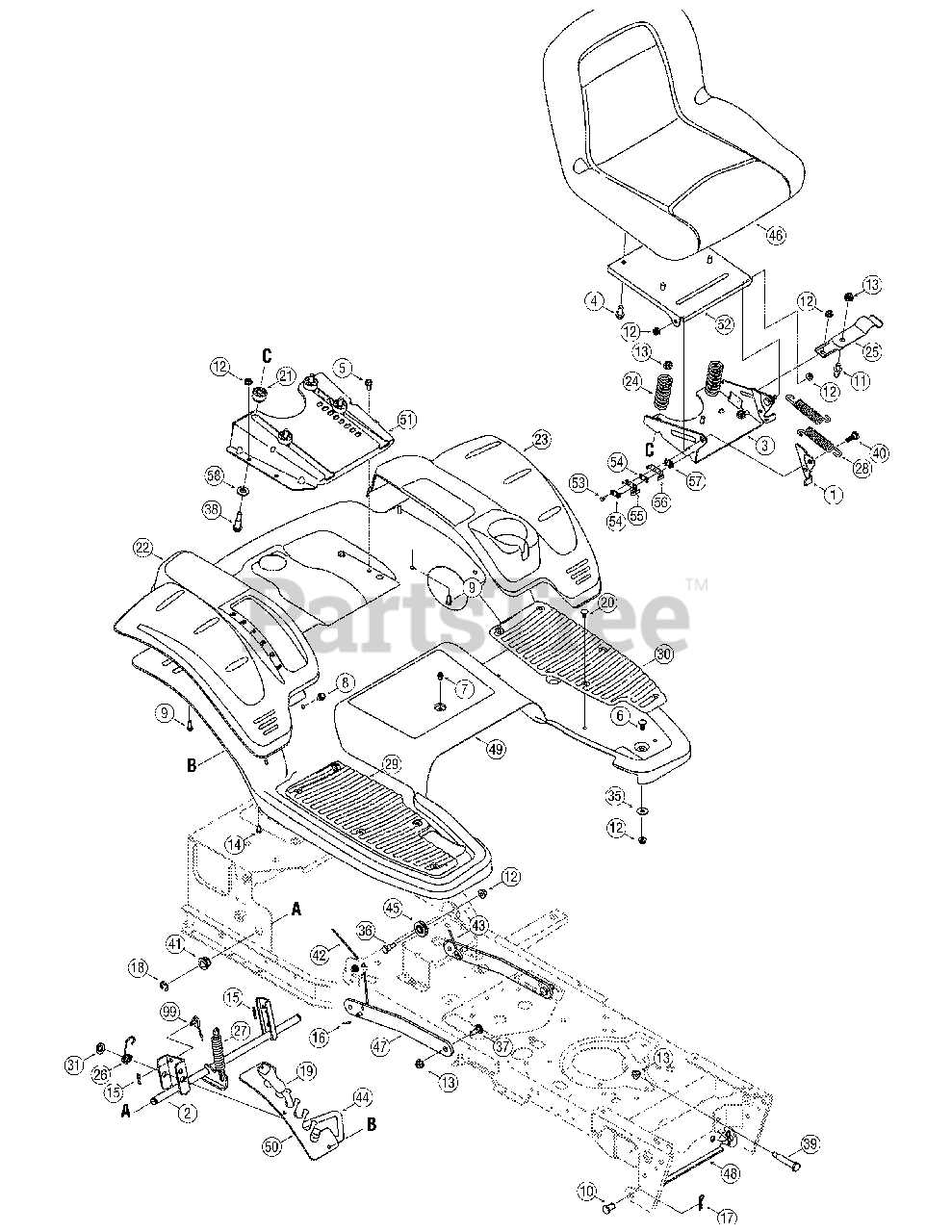

Interpreting a layout of your outdoor tool can seem overwhelming at first, but once you understand its structure, it becomes much easier to identify components and their functions. The layout offers a visual representation of how different elements are arranged and how they interact. By familiarizing yourself with the key symbols and labels, you can quickly locate parts and understand their roles in the overall system.

When looking at the layout, focus on understanding the connections between parts. Each component will be shown in relation to others, allowing you to see how they fit together. Pay attention to any numbers or labels that correspond to specific parts, as these can help when ordering replacements or identifying issues. The layout often includes directional arrows or lines to indicate movement or operation, helping clarify how energy flows through the system.

Common Repairs for Lawn Equipment

Even the most durable outdoor tools require occasional repairs to maintain optimal performance. Common issues typically arise from regular wear and tear or lack of proper maintenance. Understanding the most frequent problems and how to fix them can save time and reduce the need for professional help. By addressing small issues early, you can prevent larger, more costly repairs in the future.

Some of the most frequent repairs involve the cutting mechanism, such as replacing dull or damaged blades. Additionally, belts and pulleys often wear out, leading to reduced functionality. Another common repair is the adjustment of tension or alignment to ensure smooth operation. Recognizing these issues and performing timely fixes ensures the machine works efficiently throughout its lifespan.