When working with engine systems, having a clear understanding of each individual component is crucial for optimal performance and maintenance. Different parts play unique roles in ensuring the smooth operation of the engine, with some critical for fuel regulation, while others control airflow or ignition timing.

In this section, we will break down the various elements that make up the fuel delivery system, explaining their functions and interconnections. By examining the relationships between these elements, it becomes easier to troubleshoot issues and perform necessary repairs or upgrades.

Proper maintenance is key to keeping everything in working order. Regular checks and an understanding of how each component interacts can help prevent problems before they arise, ensuring long-term reliability and efficiency.

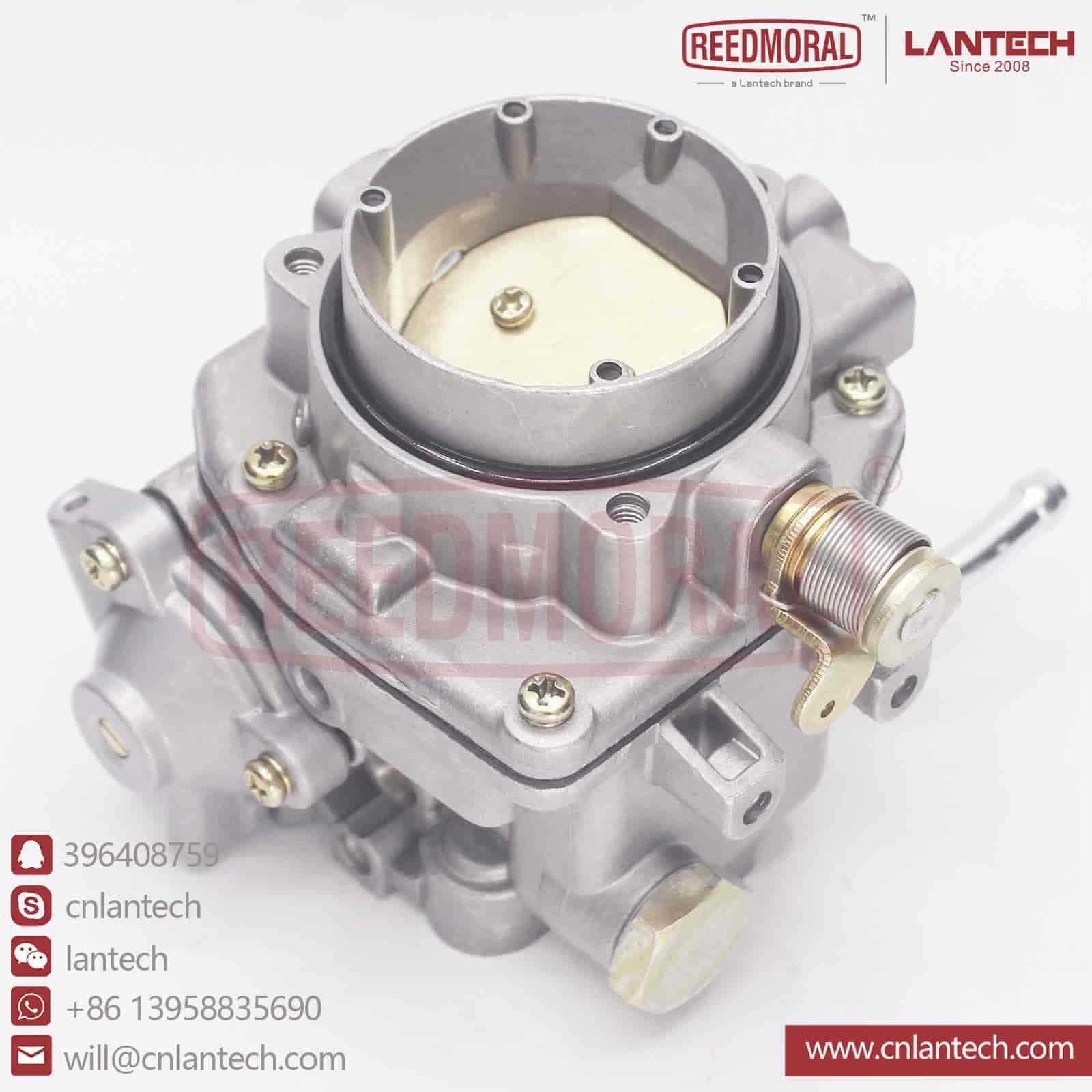

Key Components of a Carburetor

Engines rely on a variety of interconnected components to regulate fuel and air mixture, ensuring efficient combustion. Each individual element plays a vital role in the overall performance and must work in harmony for smooth engine operation.

One of the central components is the throttle valve, which controls the amount of air entering the engine, influencing power and speed. Another essential element is the float chamber, responsible for maintaining the correct fuel level, allowing the engine to run smoothly under varying conditions.

The jets are another crucial component, determining the fuel flow based on engine demand. These pieces adjust the mixture, optimizing combustion for different engine speeds. Additionally, the accelerator pump ensures that extra fuel is provided during rapid acceleration, maintaining engine performance under load.

Proper maintenance and knowledge of each component’s function are key to keeping the system in optimal condition, allowing for efficient fuel usage and improved engine longevity.

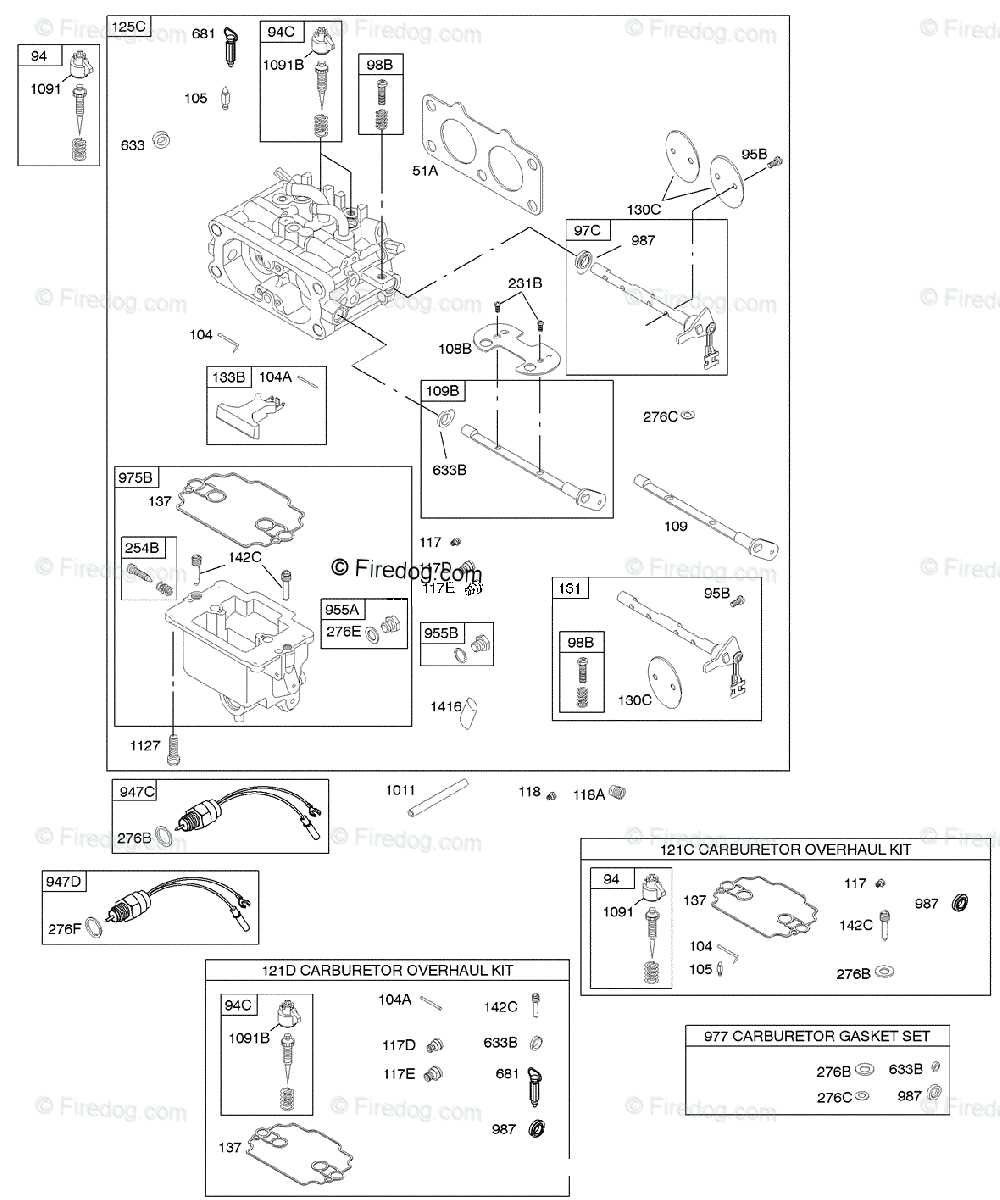

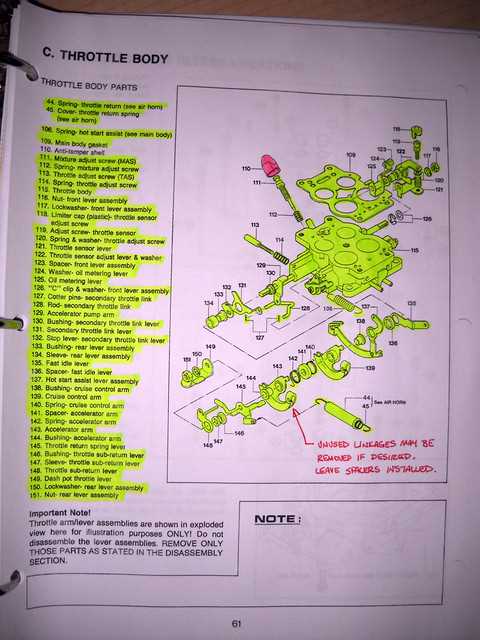

How to Read a Carburetor Diagram

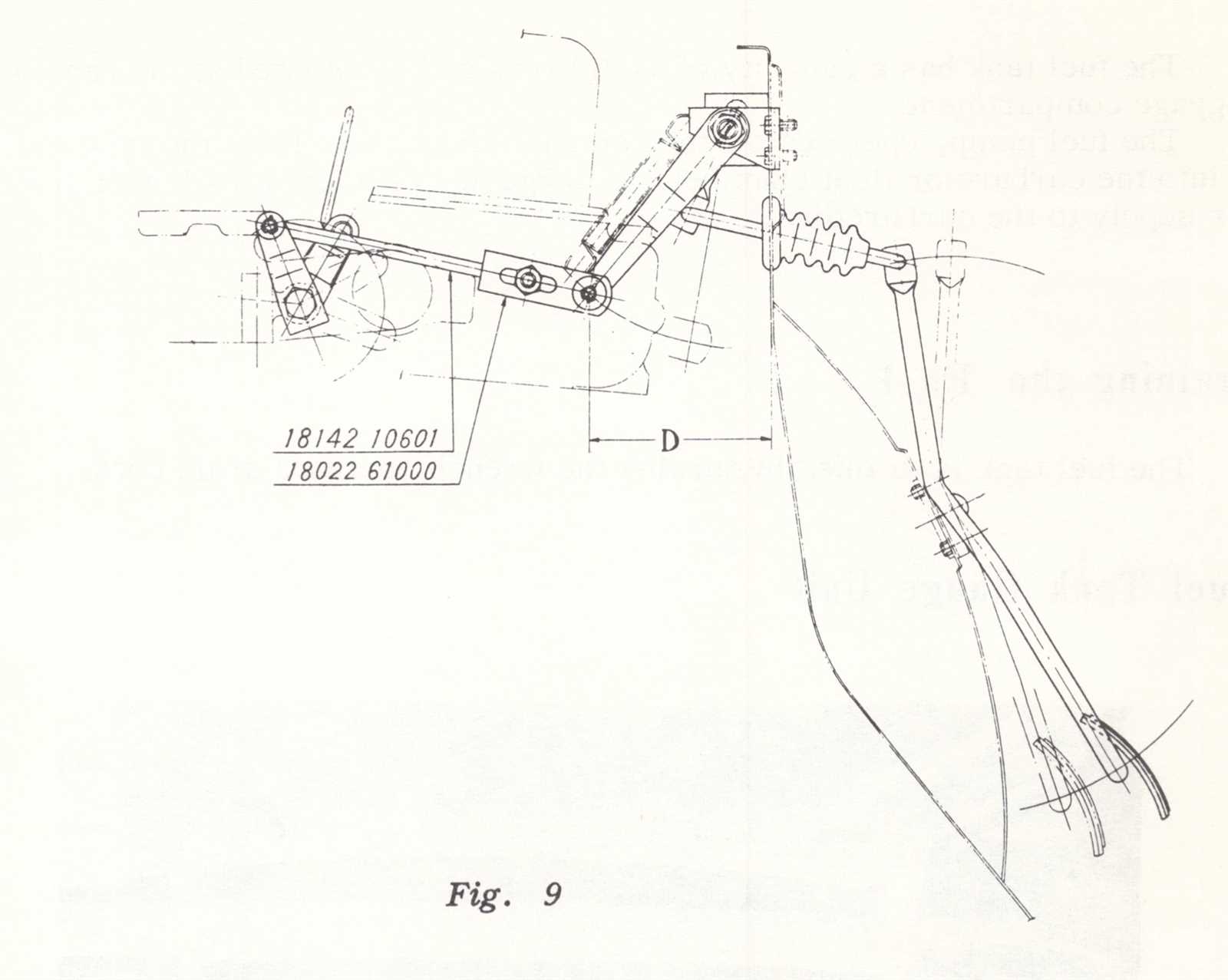

Understanding technical illustrations is an essential skill when working with engine components. These detailed images provide a visual representation of how different elements are arranged and interact with one another. By interpreting these visuals, you can gain insights into the structure and functioning of the system.

When looking at a schematic, it’s important to identify each part and its purpose within the overall system. Labels and symbols are often used to distinguish between components, helping you understand their specific roles. Pay attention to the flow lines that show how fuel or air moves through the system, and notice any annotations that indicate settings or adjustments.

Taking time to familiarize yourself with these details can greatly assist in troubleshooting and maintenance. A clear understanding of how each component fits together will allow you to make informed decisions when diagnosing problems or performing repairs.

Maintaining Your Engine Components

Proper upkeep of engine components is essential for long-lasting performance and efficiency. Regular maintenance ensures that all parts function correctly, reducing the likelihood of costly repairs and extending the lifespan of the system.

To keep everything running smoothly, consider the following steps:

- Clean the fuel delivery system: Over time, fuel lines and other elements can accumulate dirt and debris. Cleaning them regularly ensures proper fuel flow and prevents blockages.

- Inspect seals and gaskets: Check for any wear or damage to seals and gaskets. Replace them if needed to maintain a tight seal and avoid leaks that could affect performance.

- Check air and fuel mixture: Ensure the mixture is balanced for optimal engine operation. Adjust settings as necessary to maintain fuel efficiency and prevent engine strain.

- Lubricate moving components: Regular lubrication helps reduce friction, preventing wear on moving parts and ensuring smooth operation.

- Replace worn components: If you notice any part showing signs of damage or excessive wear, replace it promptly to prevent further issues.

By staying on top of these maintenance tasks, you can ensure that the entire system operates at peak efficiency, reducing the risk of unexpected breakdowns and improving overall engine performance.