When it comes to understanding how your cleaning machine functions, recognizing the key elements that make up its system is essential. Each component plays a vital role in ensuring efficient performance and longevity. Knowing these parts and their interactions can help troubleshoot issues and improve the overall maintenance process.

Regular inspection and knowledge of how different elements connect can save both time and money. Whether it’s identifying malfunctioning parts or upgrading certain sections, understanding the machinery’s layout and functions is crucial.

In this guide, we will look at the essential elements that drive your device’s performance and offer advice on keeping them in optimal condition. Proper care and attention to detail can prevent common issues and keep your equipment running smoothly for years.

Understanding the Components of Simpson Pressure Washers

Every cleaning machine consists of several interconnected elements that work together to ensure optimal operation. Understanding the function and design of each part is key to maintaining and troubleshooting the equipment effectively. Each component plays a unique role in delivering the desired performance, whether it’s generating the necessary power or controlling the flow of water.

Core Functional Elements

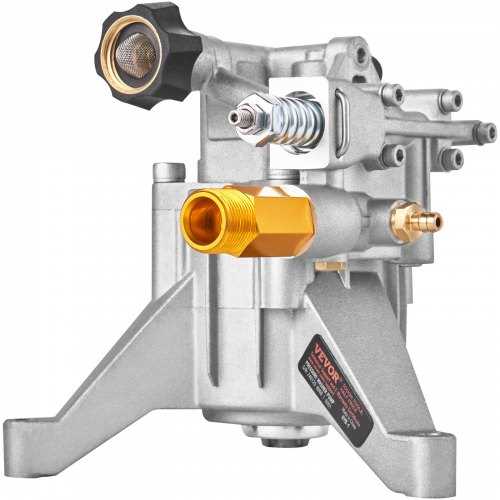

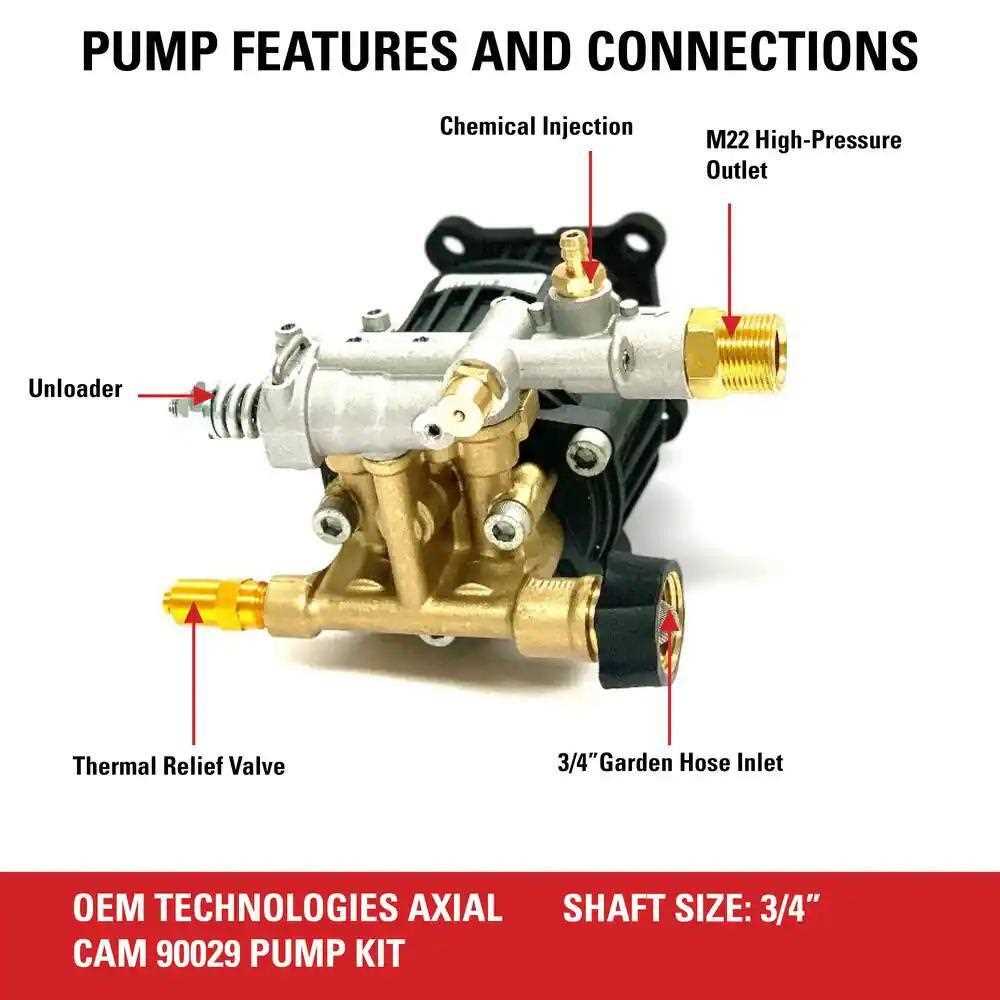

The engine or motor is the heart of the system, driving all other components. It is responsible for converting energy into mechanical force, enabling the entire machine to function. Additionally, the water inlet and outlet valves control the flow of water, ensuring that the right amount reaches the nozzle for cleaning purposes.

Supporting Features for Efficiency

Other supporting components, such as pressure regulators, hoses, and nozzles, are vital for maintaining consistent performance. These parts help manage the distribution of water, adjust the intensity of the cleaning process, and direct the flow accurately to the cleaning surface. Regular checks of these features help prevent clogging or wear, prolonging the equipment’s lifespan.

How to Identify Pressure Washer Parts

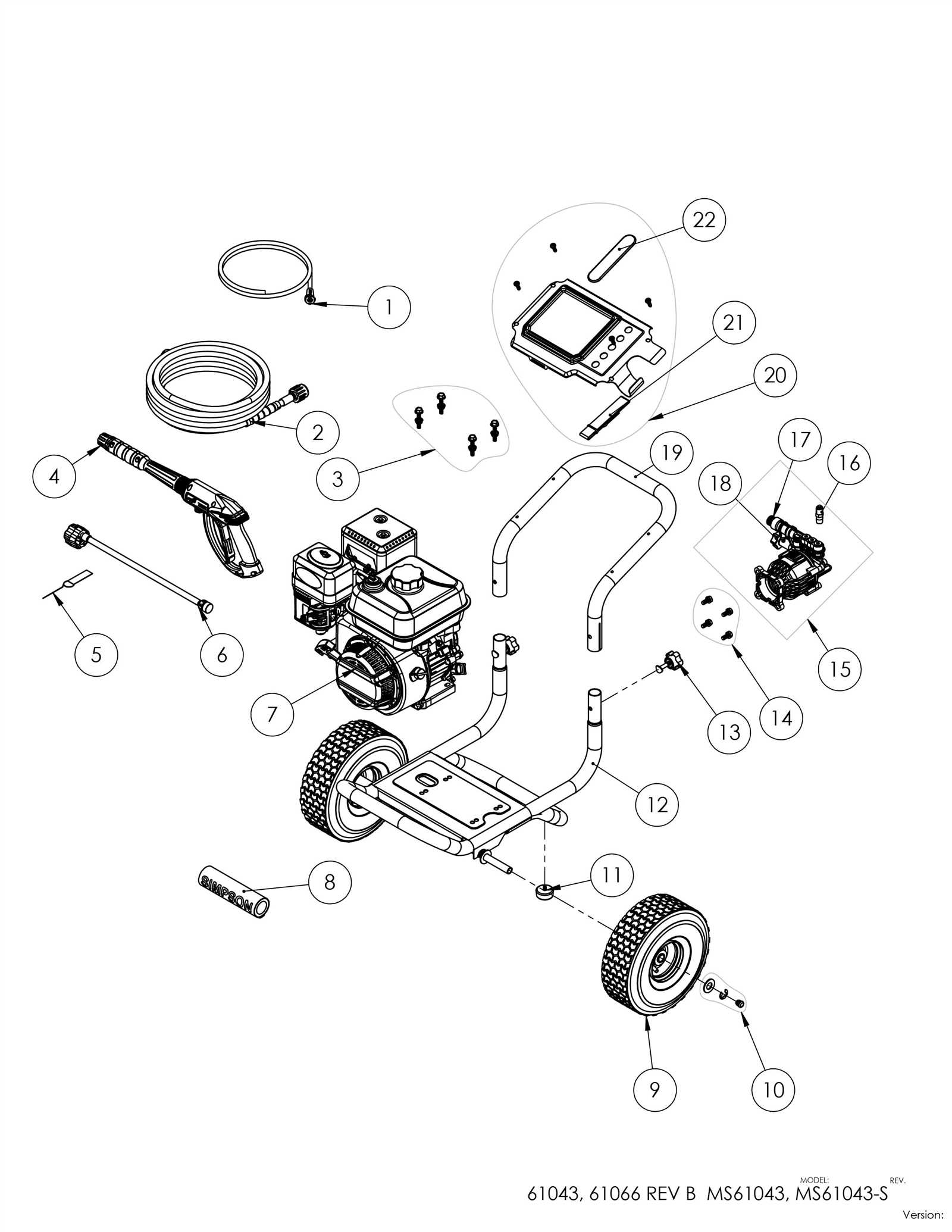

Identifying the key components of your cleaning machine is essential for maintenance, troubleshooting, and repairs. Understanding what each element does can help you recognize when something isn’t functioning properly. Knowing the different sections and how they interact ensures that you can diagnose issues accurately and take necessary actions quickly.

Common Identification Methods

There are several methods to help identify the main components of your equipment:

- Visual Inspection: Check each section for any visible labels, part numbers, or model information.

- Manual Reference: Consult the user manual to match components with their descriptions and diagrams.

- Online Resources: Use manufacturer websites or forums to search for images and descriptions of specific elements.

Steps to Identify and Troubleshoot Parts

If you suspect a malfunction, follow these steps:

- Start by turning off the equipment and disconnecting any power sources.

- Look for any damaged hoses or connectors.

- Inspect the motor or engine for unusual sounds or signs of wear.

- Examine the valves and nozzles for blockages or clogs.

- Check for any leaks around seals and connections.

Maintenance Tips for Simpson Pressure Washer Parts

Proper maintenance is crucial for extending the lifespan of your cleaning equipment and ensuring it operates at its best. Regular care of the essential elements helps prevent unexpected breakdowns and keeps your machine functioning efficiently. Understanding which components require attention and how to maintain them will save time and money in the long run.

Routine Checks: Conduct regular inspections to ensure that all elements are clean, free of debris, and functioning correctly. Pay special attention to the engine or motor for any signs of overheating or wear.

Cleaning and Lubrication: Keeping internal components clean is key. Clean the inlet and outlet valves periodically to avoid blockages. Lubricate moving parts, such as hoses and connectors, to reduce friction and extend their life.

Storage and Protection: Store your equipment in a dry, safe place when not in use. Protect sensitive components, like hoses and nozzles, from extreme temperatures and moisture. Covering your equipment during off-seasons helps maintain its condition.