Proper maintenance of any mechanical device requires a clear understanding of its internal structure. By familiarizing yourself with the different components and how they interact, you ensure the long-lasting performance and reliability of your machine. Knowing how each element fits together and functions allows for easier troubleshooting and more efficient repairs.

When you take a closer look at the breakdown of these components, it becomes easier to identify potential issues before they lead to major malfunctions. Visual guides can be incredibly useful in mapping out the connections and processes, helping to prevent unnecessary damage and enhancing the overall lifespan of your device.

Maintenance and repair become less daunting when you have a visual reference that highlights each individual part. This approach not only simplifies the process but also empowers users to carry out routine checks and fixes without professional help. With the right knowledge and tools, even complex machinery becomes manageable.

Understanding the Internal Components

To effectively maintain and repair your machinery, it’s essential to grasp how the internal mechanisms work together. Each part plays a specific role in the operation, and understanding their individual functions is key to troubleshooting issues and optimizing performance. By familiarizing yourself with these elements, you ensure that the machine operates at its best, preventing unnecessary breakdowns.

Here is an overview of the key components that contribute to the proper functioning of your device:

- Motor: Powers the entire system and drives the mechanical movement.

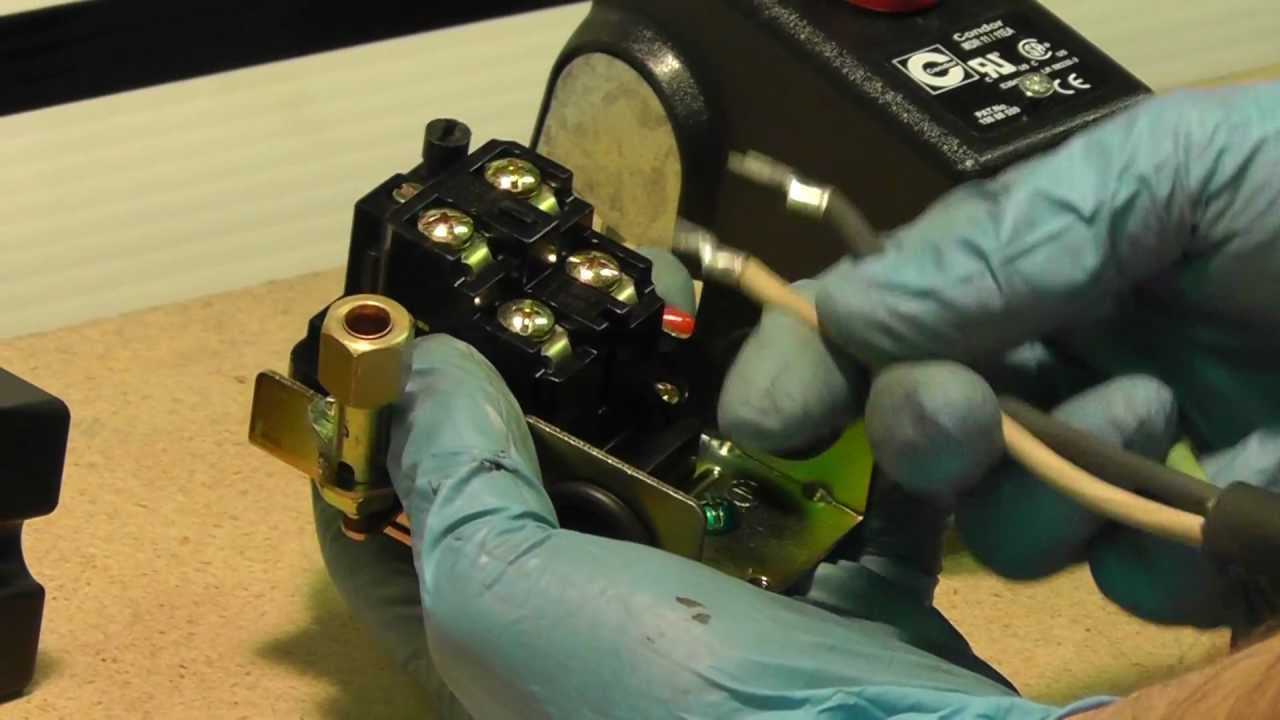

- Pressure Switch: Regulates pressure levels to ensure optimal operation.

- Valves: Control the flow of air, allowing the system to function smoothly.

- Pump: A crucial part that compresses air to the required levels for the system.

- Reservoir Tank: Stores compressed air for immediate or future use.

These components work in unison to provide the energy and functionality needed. A failure in any one of them can lead to performance issues, so it’s important to stay familiar with each piece and how they interact within the system. Regular inspection of these elements ensures that the system runs efficiently and lasts longer.

How to Read a System Component Breakdown

Interpreting a schematic of machine components can initially seem complex, but with the right approach, it becomes much easier to understand how the system works. These illustrations provide a detailed representation of each element, showing their placement and relationship with one another. By breaking down the visual guide step by step, you can quickly grasp the function of each part and how they contribute to the overall operation.

Here are some essential tips for reading a component breakdown effectively:

- Start with the labels: Most schematics include labels next to each part. These labels will help you identify the function of each component and understand how they interact.

- Look for symbols: Different symbols represent various types of components, such as valves, motors, and switches. Familiarize yourself with these to quickly recognize them on the diagram.

- Understand the flow: Follow the flow of energy or air throughout the system. This will give you insight into how the elements work together to perform specific tasks.

- Check for connections: Arrows or lines typically indicate connections between parts. Pay attention to these to understand how each element is linked.

By following these steps, you will be able to interpret any schematic and gain a deeper understanding of how each component contributes to the overall performance. This knowledge makes it easier to diagnose issues and perform repairs or maintenance tasks accurately.

Maintaining Your Equipment Effectively

Proper maintenance is crucial to ensure the longevity and efficiency of any machine. By regularly checking its internal components and following a consistent care routine, you can prevent unexpected failures and keep the system running smoothly. Routine upkeep not only helps identify potential issues early but also minimizes costly repairs in the future.

To maintain your machine effectively, follow these essential steps:

- Regular Inspections: Periodically check the internal components for wear and tear, ensuring all parts are functioning as they should.

- Cleaning: Keep the system clean to prevent dirt or debris buildup, which can cause clogs or inefficiencies.

- Lubrication: Apply lubrication to moving parts to reduce friction and prevent premature wear.

- Check Air Filters: Ensure air filters are clear to maintain proper airflow and prevent strain on the system.

- Monitor Pressure Levels: Regularly check the pressure levels to ensure they are within the optimal range for safe and efficient operation.

By staying proactive and following these maintenance practices, you can extend the lifespan of your equipment and improve its overall performance. Consistent care ensures the machine is always ready for use and reduces the risk of major malfunctions.