Proper maintenance of equipment is essential for ensuring its longevity and efficiency. A clear understanding of its various components can help users perform repairs and replacements effectively. Identifying each individual part and knowing its function is crucial for tackling any issues that may arise.

Efficient repair starts with knowledge. By familiarizing yourself with the internal structure and connections, you can quickly pinpoint any malfunctioning pieces. This not only saves time but also prevents unnecessary replacement of functioning components.

Maintaining the system in peak condition requires attention to detail. Understanding how different parts work together will help users keep their machinery running smoothly season after season, ensuring optimal performance even under challenging conditions.

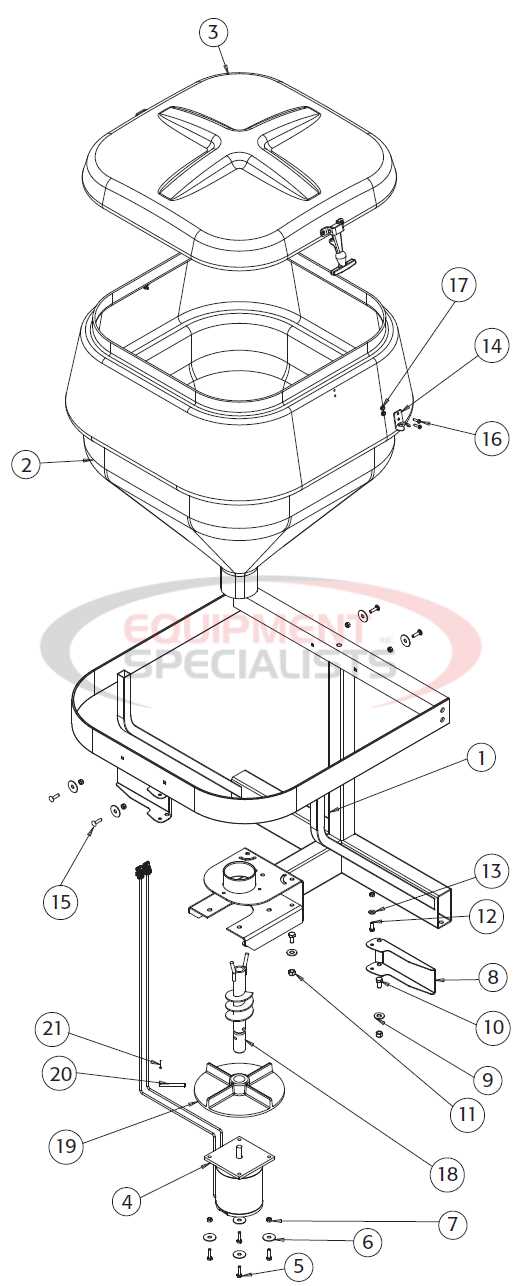

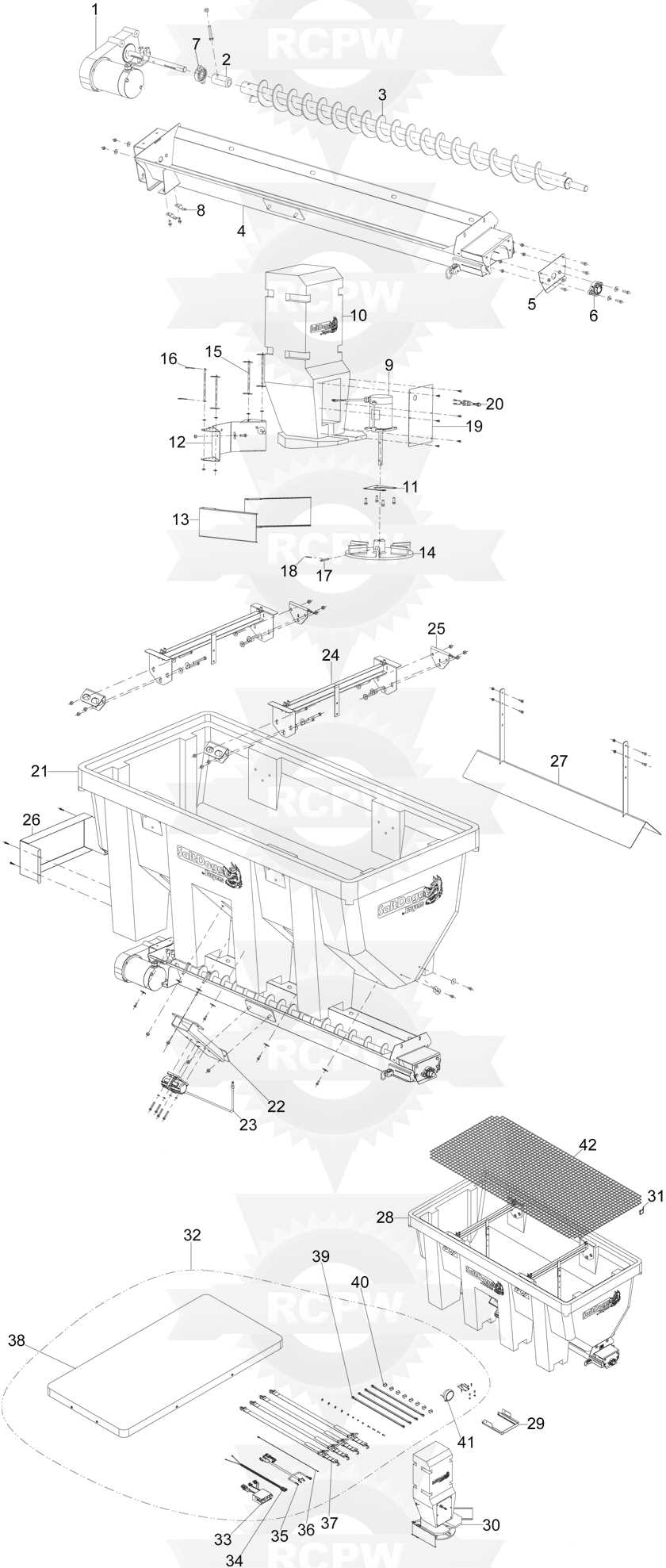

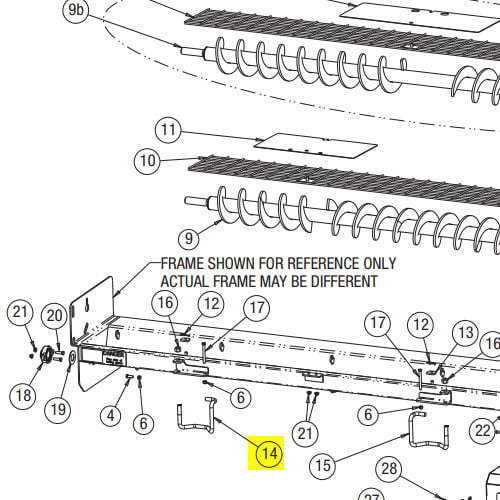

Understanding the Parts of Buyers Salt Spreader

To maintain any machinery effectively, it’s essential to grasp how its individual elements contribute to its overall function. Whether you’re repairing or replacing components, knowing each piece’s role allows for more precise work and better outcomes. By breaking down the system, it becomes easier to identify any problematic areas and keep the equipment running smoothly for longer periods.

Main Components Overview

The core structure consists of several key units that interact to perform specific functions. Each part plays an integral role, whether it’s for controlling movement, distributing material, or ensuring proper functioning. Understanding their positions and relationships is fundamental to a thorough repair process.

Essential Features to Monitor

Focus on the mechanism that drives the movement and material release. Pay special attention to the areas where wear and tear are most likely to occur, such as the transmission, motor, and distribution systems. Regular checks of these elements will ensure that your equipment remains reliable and efficient during usage.

How to Identify Key Components in the Diagram

Identifying essential elements in a system requires a methodical approach, focusing on the different components that interact to ensure functionality. A visual guide can be extremely helpful in recognizing these critical parts, but knowing how to interpret the markings and labels is key to success. Once you can differentiate each section, maintenance and repairs become much more manageable.

Start by locating the major sections, such as the motor, transmission, and distribution system. These areas are typically highlighted for easy identification. Once these core parts are clear, focus on the connectors, bearings, and any auxiliary elements that support the primary components.

Understanding placement and connections is crucial. Pay attention to the way each part links to others, as this will give you insight into how the system operates as a whole. This knowledge will make it easier to spot issues and perform the necessary fixes efficiently.

Steps to Replace Buyers Salt Spreader Parts

When a component within the system becomes damaged or worn out, replacing it promptly is essential to maintain overall performance. The process of replacing a part may seem daunting, but following a clear set of steps can make it much easier. By understanding the replacement procedure, you can ensure the equipment functions properly after the fix.

Preparation and Safety

Before beginning any replacement, make sure the system is turned off and disconnected from power sources. Safety gear, such as gloves and goggles, should be worn to prevent injury during the process. Gather all necessary tools and new components to avoid interruptions while working.

Removal and Installation

Once you’re prepared, carefully remove the damaged part by unscrewing or disconnecting it from the system. Take note of the configuration for reassembly. Once removed, install the new part in the same manner, ensuring it’s securely connected and properly aligned. Double-check all connections before reactivating the equipment.