For those who own vintage machinery, knowing the internal structure and connections is crucial for effective troubleshooting and repair. A clear visual reference can make the process of identifying issues and performing maintenance much easier. Whether you are restoring a classic model or simply need to replace a worn-out component, understanding how each element fits together is key.

By studying the schematics of these models, you gain insight into the layout and function of the various mechanisms. This knowledge helps to prevent unnecessary damage, ensures proper functionality, and allows for a more efficient repair process. With the right guide, anyone can confidently take on repairs without confusion.

Detailed references provide a roadmap for anyone looking to maintain or restore older models, offering step-by-step guidance through each stage of the process. Familiarity with these essential components leads to improved performance and longevity of the equipment.

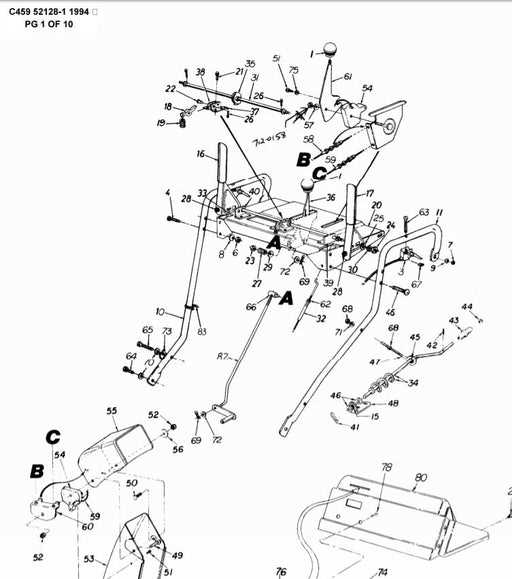

Understanding the Component Layout

Knowing how the different elements of a machine are arranged is crucial for proper maintenance and repairs. The layout provides a roadmap for identifying which parts need attention and how they interact with each other. By understanding this structure, you can troubleshoot more effectively and ensure that each mechanism is working as it should.

Key Elements of the Structure

Each model features a unique arrangement of mechanical and electrical components. The primary focus should be on the engine, drive system, and the various controls. Understanding how power flows through the system helps to pinpoint issues, such as power loss or malfunctioning components. The layout also highlights critical points that may require lubrication, tightening, or occasional replacement.

Maintenance and Repair Tips

Proper maintenance involves more than just replacing worn parts. Knowing the location of each element and how they function together allows for preventive care. Regularly checking belts, bolts, and other mechanical systems can prevent more serious damage and extend the lifespan of your equipment. Always consult the layout to ensure that each component is in the right position and functioning optimally.

Identifying Key Elements in Older Models

When working with vintage machinery, recognizing the essential components is crucial for effective repair and maintenance. Each machine has a unique design, but there are common elements that perform critical functions. Understanding the role of these key components helps you identify potential issues and determine the necessary steps to restore the equipment to full working condition.

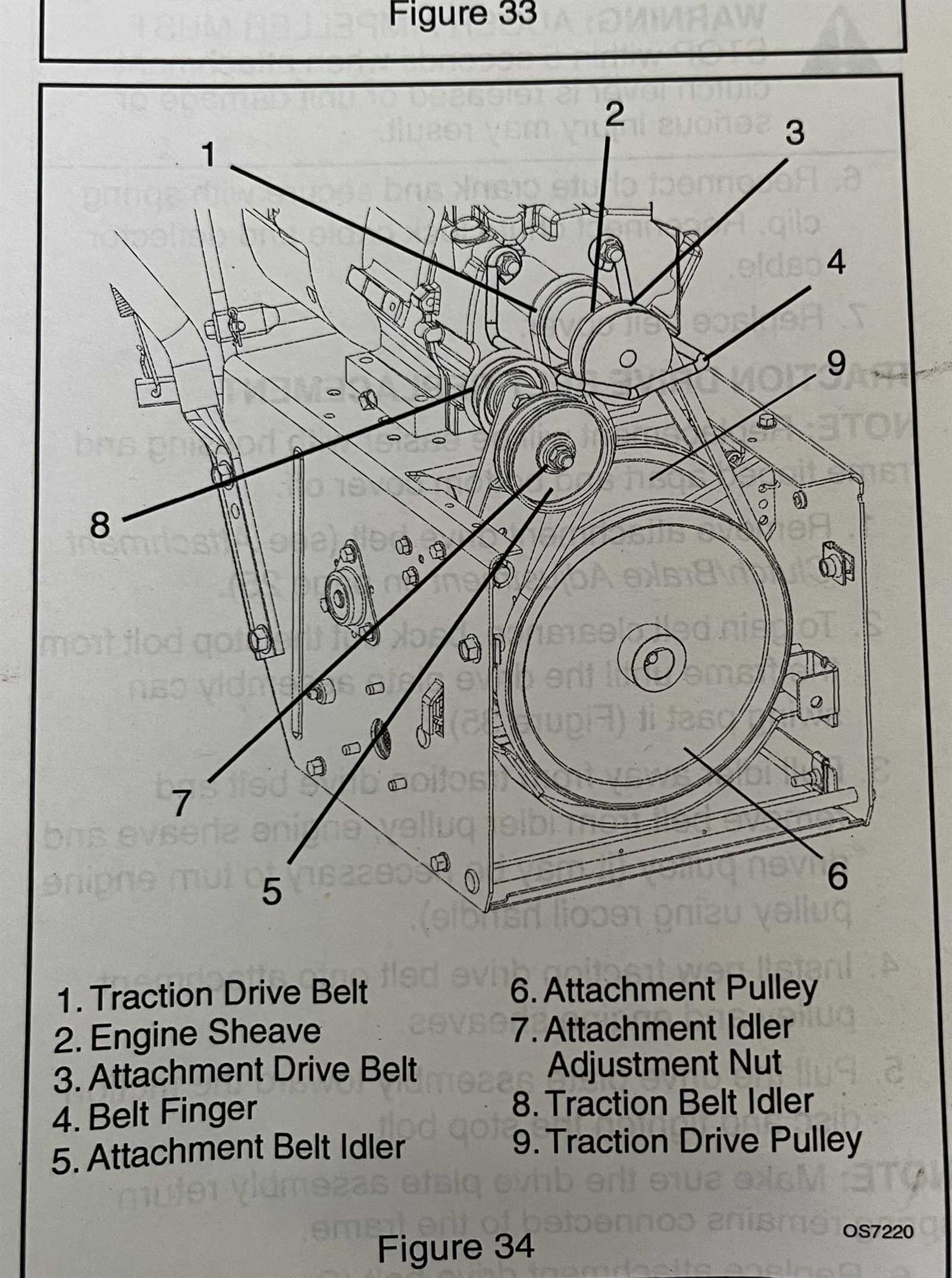

Main Mechanisms to Focus On

The engine, transmission, and intake system are typically the primary elements that require attention. The engine serves as the powerhouse, and understanding its connections to the rest of the system is vital for troubleshooting. The transmission, responsible for power transfer, must be examined for wear and tear, as it often experiences the most strain during operation. Finally, the intake system plays a role in efficiency, and any blockage or damage to this area can significantly reduce performance.

Essential Tools for Identification

Having the right tools is important when identifying and inspecting the components. A detailed schematic can guide you in locating specific areas of interest, but visual inspection with proper lighting and magnification may reveal additional clues. Basic tools such as wrenches, screwdrivers, and torque wrenches can help with disassembly and reassembly, while specialized tools are required for checking internal mechanisms like bearings and seals.

Step-by-Step Repair and Maintenance Tips

Regular upkeep and careful repair are essential for keeping machinery in top working condition. A structured approach to maintenance helps prevent future issues and ensures efficient operation. Follow these step-by-step tips to maintain optimal performance and extend the lifespan of your equipment.

Pre-Maintenance Preparation

Before starting any repair or maintenance task, ensure you have the necessary tools and safety equipment. A clean workspace and a proper understanding of each component are key to avoiding mistakes. Here are the initial steps to follow:

- Gather essential tools, such as wrenches, pliers, and screwdrivers.

- Wear safety gloves and goggles to protect yourself from debris and sharp edges.

- Disconnect any power sources to avoid accidental startups.

- Consult the equipment’s manual for specific guidelines on the model you are working with.

Maintenance Tasks and Repair Steps

Once you’ve prepared the workspace, follow these steps to maintain and repair the machine:

- Inspect the drive system for any signs of wear, such as frayed belts or loose connections.

- Check and clean the engine air filters to ensure proper airflow and prevent clogging.

- Lubricate moving parts, such as gears and axles, to reduce friction and prevent premature wear.

- Examine the intake system for blockages or damage that could hinder performance.

- Test electrical connections, ensuring all wires are secure and undamaged.

- Replace any worn-out components like belts, seals, or spark plugs as necessary.