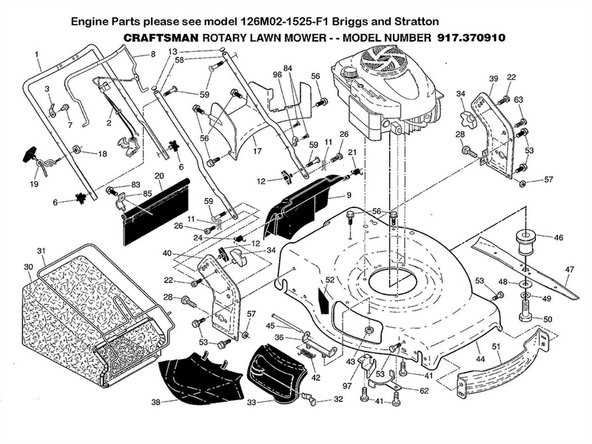

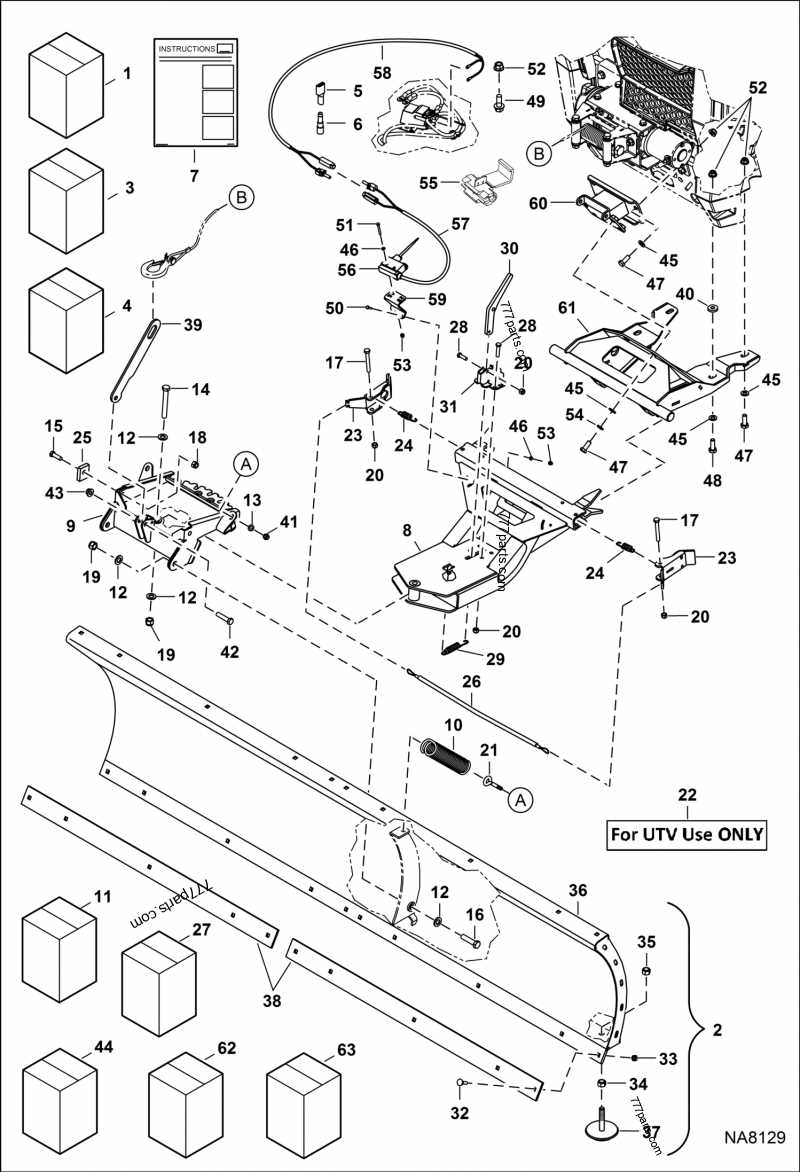

When working on any complex machine, having a clear visual representation of its structure is essential. By breaking down each individual element and understanding how they fit together, you can perform maintenance or repairs more efficiently. A well-organized schematic provides valuable insight into the device’s overall functionality.

Accurate identification of each section allows you to identify specific parts that need attention. This guide aims to simplify the process by providing an overview of crucial elements, helping you gain a deeper understanding of the system’s workings.

Whether you are troubleshooting an issue or planning for regular upkeep, a comprehensive map of the internal parts serves as a roadmap, saving time and reducing errors. Mastering this will empower you to confidently handle any task related to the machine.

Understanding Key Components

To effectively maintain or repair any mechanical system, it’s essential to comprehend the individual elements that make up the whole. Each component plays a specific role, and understanding these roles ensures that you can troubleshoot issues or perform necessary upgrades with precision. By focusing on the key sections, you can enhance your ability to perform tasks efficiently and avoid unnecessary errors.

Identifying Critical Elements

In any complex machine, there are certain components that are crucial to its operation. These elements are typically responsible for the most vital functions, such as power distribution, control, and motion. Recognizing which parts are involved in these functions helps streamline maintenance efforts, enabling you to address problems effectively.

System Interaction and Functionality

The interaction between different sections of the system is what makes it work smoothly. Understanding how each element contributes to the overall performance can prevent damage and ensure longevity. A comprehensive understanding of how these components work together is vital for troubleshooting, repairs, and ensuring the system’s continued success.

Essential Components of the Machine

Understanding the key elements that form the core of any mechanical device is crucial for effective operation and maintenance. These fundamental components ensure that the system runs smoothly and can handle various tasks without failure. By familiarizing yourself with these essential sections, you gain the knowledge needed to diagnose issues and carry out necessary repairs.

Each segment of the system serves a distinct function, from power generation to control and movement. Identifying these crucial parts allows for a more systematic approach when dealing with repairs or upgrades, ensuring efficiency and minimizing downtime. Knowing which parts to focus on can save time and prevent unnecessary replacements.

How to Use the Schematic

Understanding how to navigate a visual representation of a machine’s components is essential for both maintenance and repairs. A schematic serves as a map, guiding you through the various sections and helping you identify each part’s role within the system. By learning how to interpret these visuals, you can work more efficiently and address issues with greater confidence.

Step-by-Step Identification

Start by identifying the main sections in the schematic. These sections are usually organized logically, grouping related components together. By following this structure, you can locate each individual part and gain insight into its function and position within the system.

Using the Schematic for Troubleshooting

When facing a malfunction, the schematic can be an invaluable tool for pinpointing the problem. By referencing the diagram, you can trace the flow of power or signals to identify faulty elements. This method reduces the guesswork, allowing for more precise diagnostics and faster repairs.