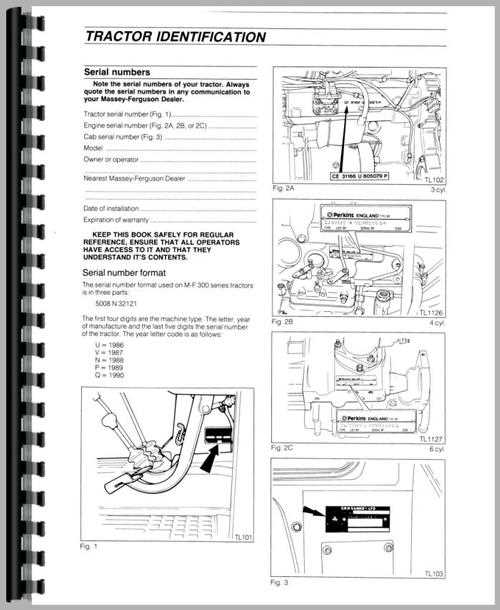

Understanding the individual components of a tractor is essential for effective maintenance and repairs. With the right knowledge, identifying and replacing worn-out parts becomes a straightforward task, ensuring the machinery operates smoothly and efficiently for a longer time.

This section provides a detailed breakdown of the key elements found in heavy-duty agricultural vehicles, offering guidance on how to interpret technical schematics. Whether you’re a seasoned mechanic or a tractor owner, the ability to read these diagrams accurately can save both time and money in the long run.

In addition to providing a visual representation, the information here will also help you identify commonly used replacements and troubleshoot potential issues that might arise with the vehicle’s system.

Understanding Tractor Components

Every vehicle is made up of various systems and individual elements that work together to ensure optimal performance. In agricultural machinery, recognizing these key components is crucial for maintenance, troubleshooting, and effective repairs. Understanding how each element functions within the larger system can greatly enhance the ability to maintain and operate the vehicle efficiently.

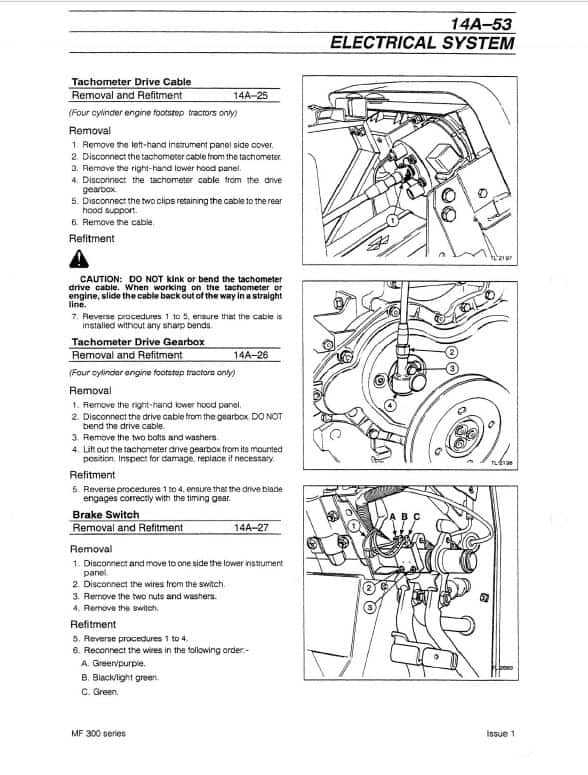

The structure of these machines includes a range of mechanical, hydraulic, and electrical systems. Each system plays a vital role in ensuring smooth operation, from powering the engine to controlling movements and lifting heavy loads. Familiarity with the key components allows operators to pinpoint issues more easily and address them before they lead to significant failures.

Identifying the correct components and their functions helps in selecting the right replacement items when repairs are needed. A well-maintained machine not only performs better but also has a longer lifespan, reducing overall costs and downtime. By grasping the layout and purpose of these systems, users can improve their troubleshooting skills and ensure their machinery is always ready for the next task.

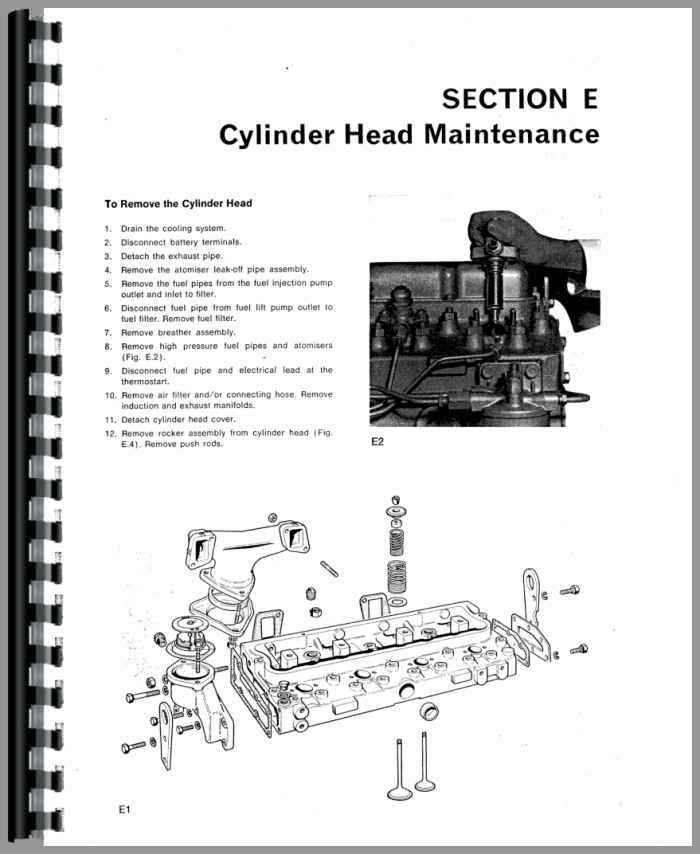

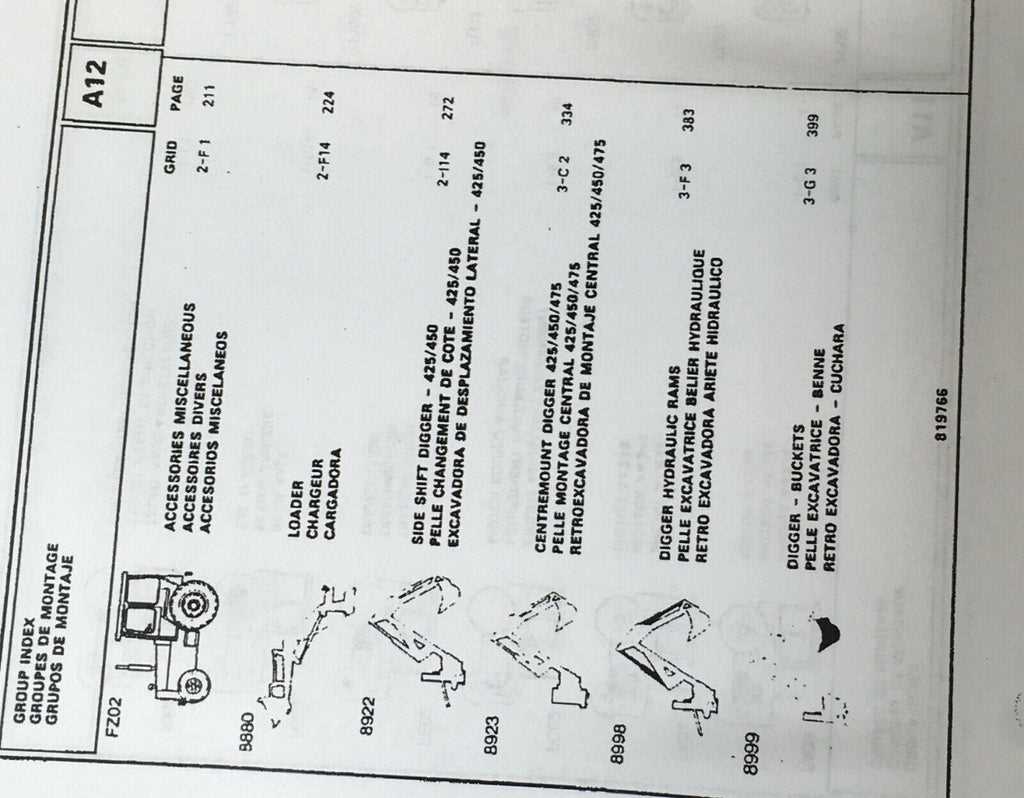

How to Read the Parts Diagram

Understanding technical schematics is an essential skill for anyone working with machinery. These visual guides provide an organized view of how various components are connected, making it easier to identify each part and its function. Properly interpreting these diagrams can save time during repairs and help in locating specific elements within a machine.

Breaking Down the Symbols and Labels

Each diagram uses standard symbols to represent specific components. These symbols are accompanied by labels that describe the part’s name and sometimes its specifications. It’s important to familiarize yourself with these symbols, as they allow you to quickly identify the elements of the machine you are working on. In many cases, these labels also provide useful information about part numbers or maintenance instructions.

Identifying the Relationships Between Components

While symbols indicate individual parts, lines and arrows are used to show how these parts are interconnected. Following these connections helps in understanding how different systems within the machine work together. It also provides a clear path for disassembly and reassembly, which is particularly useful for troubleshooting or replacement tasks.

Key Spare Parts for Tractor Maintenance

For smooth and efficient operation, heavy-duty machines rely on a variety of essential components. These key elements are crucial for maintaining performance, and knowing which parts need regular attention can help extend the life of the vehicle. Identifying and replacing worn-out elements promptly ensures that the machinery remains in top working condition, minimizing downtime and repair costs.

Commonly Replaced Components

Engines, transmissions, and hydraulic systems are among the most frequently serviced systems. Regular checks on components like filters, belts, and seals are necessary to avoid breakdowns. In addition, key items such as the alternator, starter motor, and fuel injectors may require periodic replacement to maintain optimal functionality. Keeping spare versions of these essential items can significantly reduce repair times and prevent delays during heavy work cycles.

Why Regular Maintenance Matters

Maintaining a consistent schedule for replacing crucial components ensures that the vehicle operates efficiently and avoids unexpected malfunctions. Over time, parts can degrade due to wear, exposure to harsh conditions, or inadequate lubrication. Staying ahead of these issues by replacing worn parts before they fail helps prevent major system failures, saving both time and money in the long run.