Proper maintenance of outdoor machinery is crucial for ensuring long-term efficiency and reliability. Having a clear understanding of how different components fit together and work can make repairs and upkeep much easier. Whether you are dealing with a small motorized unit or a more complex machine, knowing each part’s role helps you make informed decisions during maintenance sessions.

In this guide, we will break down the key elements of your machine, providing you with a detailed reference for easier troubleshooting. Visual aids play a significant role in identifying individual components, so you will find useful information that allows you to understand the layout and structure of your gear.

Effective maintenance requires attention to detail. By learning the essential components and their functions, you can address issues promptly, avoiding unnecessary downtime. With the right knowledge, you’ll be equipped to handle routine care and make repairs as needed.

Understanding Your Outdoor Equipment Components

When it comes to maintaining your outdoor machinery, understanding its internal structure is vital. Each piece of the system plays a specific role, working together to ensure efficient operation. Recognizing how components are connected and how they function will help you troubleshoot issues, perform routine checks, and handle repairs more effectively.

The core components of your machine are designed to withstand harsh conditions while providing reliable performance. From the drive mechanism to the cutting blades, each element contributes to the overall function of the system. Learning about these parts will allow you to better assess the condition of your equipment and identify any wear or damage that may need attention.

By becoming familiar with the essential components, you’ll gain the knowledge necessary to keep your equipment running smoothly throughout its service life. Proper understanding ensures you can perform timely maintenance and avoid unnecessary repairs, leading to more efficient operation during critical times.

How to Use a Snowblower Parts Diagram

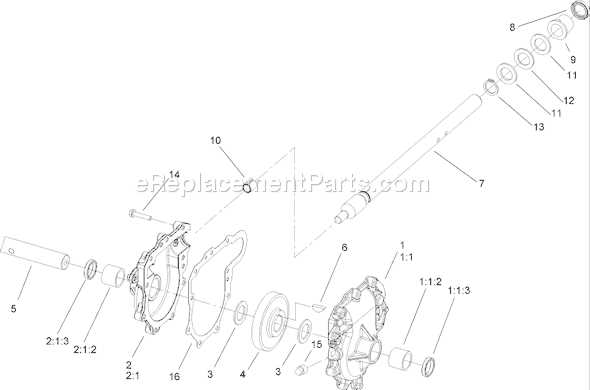

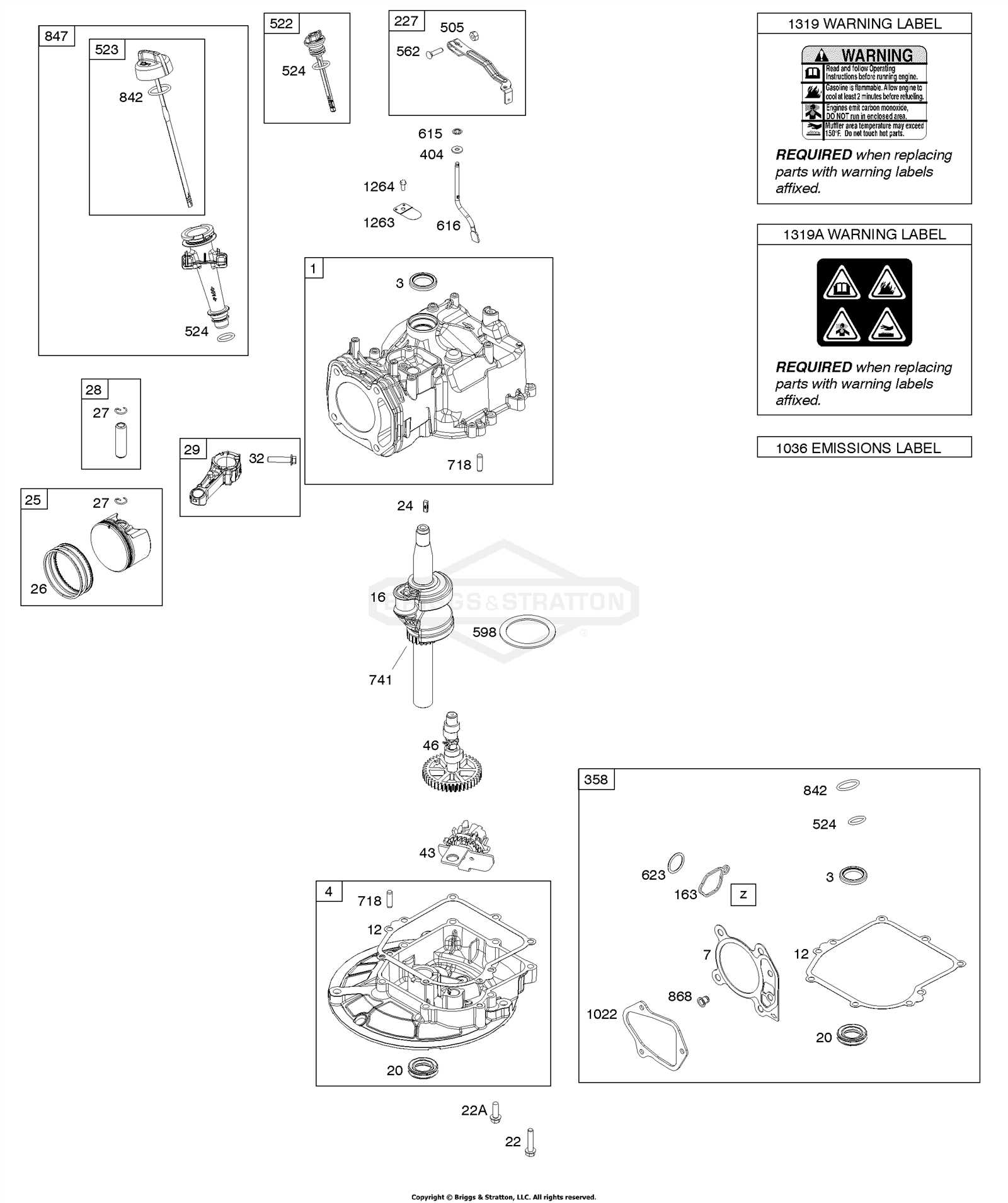

Visual references are incredibly useful when it comes to understanding the structure of mechanical equipment. They help you quickly identify different sections and components, making it easier to troubleshoot or perform maintenance tasks. By using a detailed reference guide, you can pinpoint the exact location of each piece, simplifying repairs and upkeep.

To effectively utilize such a reference, start by familiarizing yourself with the layout. Look for labels and identify the major sections, such as the engine, drive components, and operational mechanisms. Understanding the flow of parts will help you see how they interact, and where potential issues might arise.

Using the guide properly will allow you to assess the condition of each element and determine if any parts need replacing or adjustment. This process ensures that you can maintain your equipment without unnecessary confusion, keeping it in peak operating condition for years to come.

Common Maintenance Tips for Snowblower Parts

Maintaining your outdoor equipment is essential for ensuring its longevity and optimal performance. Regular upkeep prevents wear and tear, helping to avoid costly repairs. By performing simple tasks, you can ensure your machinery runs smoothly through every season, especially when it’s needed most.

Check and Replace Wearable Components

Components such as belts, augers, and the drive mechanism are subject to significant wear over time. Inspect these parts regularly for signs of damage or excessive friction. Replacing worn-out parts promptly can prevent further damage and ensure the machine operates without issues during heavy use.

Lubricate Moving Parts

Keeping moving elements well-lubricated reduces friction and helps maintain smooth operation. Pay attention to areas like the chute and the drive shaft. Use the recommended lubricants for your equipment to avoid causing any harm or reducing efficiency. Regularly oiling these parts can extend the lifespan of your machine and reduce maintenance needs.