Maintaining and troubleshooting your equipment requires a clear understanding of its individual parts and how they function together. Knowing the layout and specific components is crucial for ensuring smooth operation and prolonging the lifespan of your sprayer.

In this section, we will provide an in-depth look at the various internal elements that make up the sprayer, highlighting their roles and how they contribute to the overall performance. Having this knowledge will help you perform repairs or routine maintenance more efficiently.

By becoming familiar with these essential components, you will be better equipped to handle issues that arise and keep your device working optimally. Whether you are replacing a faulty piece or performing general upkeep, understanding how everything fits together is key.

Understanding Sprayer Components

The effectiveness of any sprayer relies heavily on the interaction between its internal components. Each element plays a specific role in ensuring smooth operation, whether it’s delivering consistent pressure, controlling the flow, or providing safety mechanisms. A solid grasp of how these components work together can significantly improve the device’s performance and longevity.

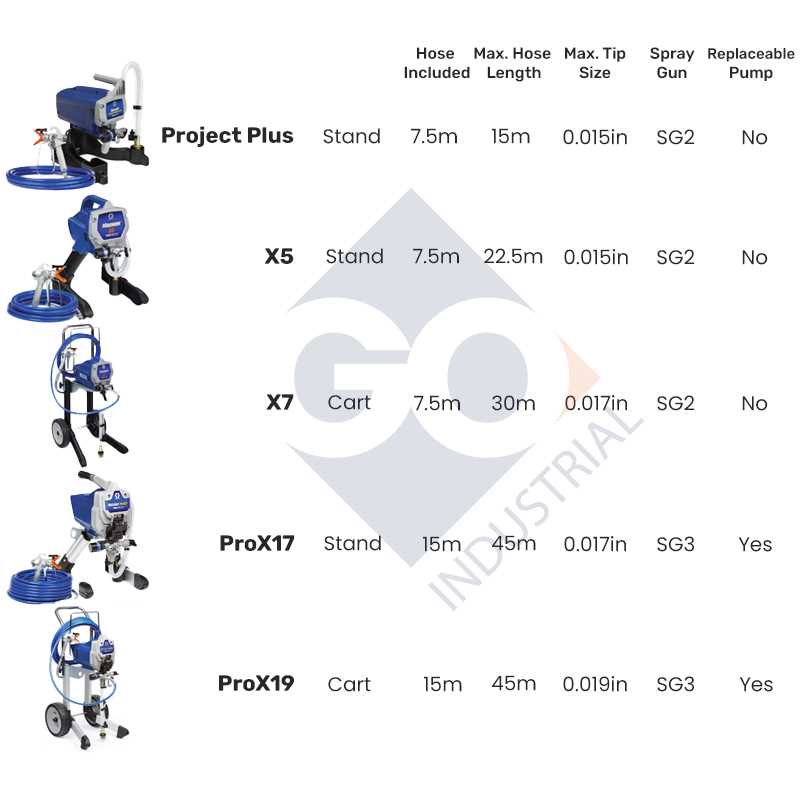

Key parts of the sprayer include the motor, hose, nozzle, and various valves. These elements work in unison to produce an efficient spraying system. A malfunction in any one of these components can lead to reduced functionality, making it essential to understand their functions and the importance of regular checks and maintenance.

In addition to the core components, accessories and attachments also contribute to the versatility of the sprayer. These can range from filters to specialized nozzles, each designed for specific tasks. Understanding the full range of components allows you to customize your device to suit different projects and ensure that every part is functioning at its best.

How to Read the Component Layout

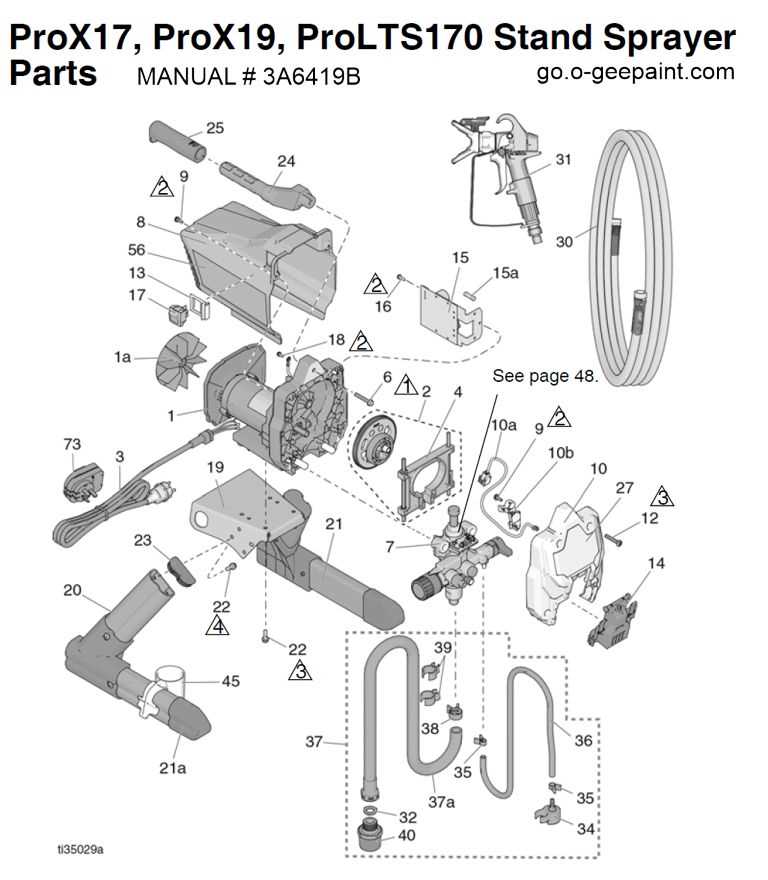

Understanding the layout of the internal elements of a sprayer is key to troubleshooting, maintaining, or upgrading your equipment. A visual representation helps identify each component and its specific function within the system. Knowing how to interpret these layouts will make it easier to diagnose issues and find the right replacement parts when necessary.

Key Symbols and Labels

Each component in the visual guide is labeled with either a unique number or name. These identifiers are crucial for tracking down specific parts, ensuring you order the correct ones. Here’s how to interpret them:

- Numbers: Often correspond to a specific part within the manual, indicating size, model, or function.

- Arrows: Show the direction of flow or movement within the system, guiding you through the operational process.

- Lines: Represent connections between components, such as hoses or electrical wiring.

Reading the Layout Step-by-Step

Follow these steps to properly read and understand the visual representation of the internal elements:

- Start by locating the main components, such as the pump, motor, and spray nozzle.

- Examine the connection points between components to see how they interact and depend on each other.

- Check for any specific instructions or troubleshooting tips noted near certain components, which may indicate common issues or maintenance requirements.

Common Issues with Sprayer Components

While sprayers are designed for durability and efficient operation, certain components can experience wear and tear over time. Identifying these issues early can save time and money on repairs. Common problems typically arise from the motor, hose, valves, or nozzles, all of which can affect the sprayer’s overall performance.

Motor Malfunctions

The motor is essential for powering the system, but it is susceptible to overheating, electrical failures, or clogging. If the motor fails to start or operates intermittently, it could be due to an internal electrical issue, a blocked intake, or a worn-out part that requires replacement.

Clogged or Damaged Nozzles

Nozzles can become clogged due to debris or dried liquid, which can disrupt the flow. If the spray pattern becomes uneven or weak, it’s likely that the nozzle needs cleaning or replacing. In some cases, damaged nozzles may require a full replacement to restore functionality.

Identifying and addressing these issues promptly ensures that your sprayer continues to perform at its best, avoiding potential breakdowns and improving its longevity. Regular maintenance and care of components can prevent most of these problems from occurring.

Identifying Components for Repair

When a sprayer begins to show signs of malfunction, pinpointing the exact component causing the issue is the first step toward an effective repair. Each part plays a specific role in the overall system, and understanding how they interact will allow you to identify the root cause of the problem. The key is to systematically check each element and evaluate its condition for signs of wear or failure.

Start by inspecting the most common trouble areas, such as the motor, hose connections, and spray nozzle. These components are often the source of issues like inconsistent spraying, low pressure, or failure to start. Look for visible signs of damage such as cracks, leaks, or blockages that could impede proper function.

Next, consider any internal components that may be harder to access but are just as crucial to the sprayer’s operation. Valves and seals can deteriorate over time, leading to leaks or reduced performance. Regularly checking these parts ensures you catch potential problems before they become more serious.

Maintaining Sprayer Efficiency

Ensuring the long-term functionality of your sprayer requires consistent care and attention to its core components. Regular maintenance not only helps to prevent unexpected malfunctions but also boosts overall performance. Proper upkeep can make a significant difference in how efficiently the system operates, ultimately saving time and reducing repair costs.

One of the key aspects of maintaining efficiency is cleaning. After each use, it’s essential to clear any residue from the nozzle, hoses, and other areas where liquid may have dried or built up. A clean system will reduce the chances of blockages, ensuring that the sprayer delivers an even and continuous flow every time.

Routine checks on moving parts, such as the pump and motor, can also prevent wear and tear from affecting the sprayer’s performance. Replacing worn seals or filters before they cause major issues will keep the system running smoothly. Additionally, keeping an eye on the hose and power cables for any signs of damage ensures safe and efficient operation.

Lastly, always refer to the manufacturer’s guidelines for specific maintenance intervals and procedures. Staying on top of recommended servicing schedules ensures that your sprayer performs at its best, day after day.