Maintaining a chainsaw involves more than just fueling it and checking the chain. Proper care requires a thorough understanding of its inner workings. This section delves into the essential elements that make up the machine, offering a comprehensive look at its individual parts and how they function together. A well-informed owner can ensure longevity and optimal performance by identifying each component’s role in the system.

For anyone looking to repair or replace damaged parts, having a clear visual guide is crucial. Recognizing the specific functions of different elements can simplify the process of identifying wear or malfunction. Additionally, understanding the layout and connections between parts ensures that you make the right replacements and avoid unnecessary repairs. Knowledge of the system not only helps in troubleshooting but also improves overall machine efficiency.

Whether you’re a professional user or a hobbyist, recognizing the key components and knowing their position within the machine can save time and effort during maintenance. This guide serves as a valuable resource for anyone aiming to keep their equipment in peak working condition, preventing downtime and enhancing its lifespan.

Overview of Stihl MS 261 Parts

A chainsaw consists of various interconnected components, each playing a vital role in its performance. Understanding the overall structure and function of each part is crucial for proper maintenance and troubleshooting. These elements work in harmony to ensure the smooth operation of the machine, and having a clear understanding of their arrangement can make repairs and replacements more efficient.

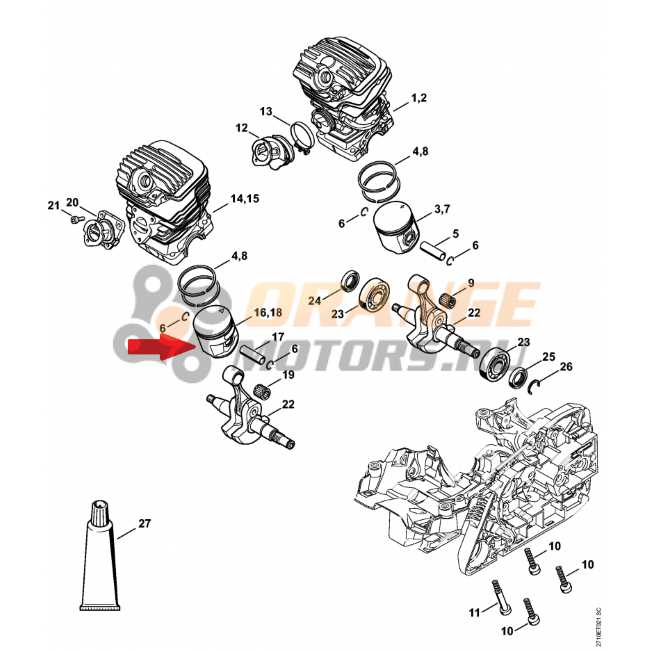

Key sections of the saw include the engine, cutting system, and the safety mechanisms that protect the user. The engine components, such as the cylinder and piston, are responsible for powering the chainsaw, while the cutting system involves the chain, bar, and tensioning elements. The safety features, including the brake and throttle, ensure secure operation during use. Each of these systems interacts to create a balanced and effective tool for various cutting tasks.

By becoming familiar with the essential components of a chainsaw, you’ll be better equipped to identify problems and make informed decisions during repairs or upgrades. Understanding these core sections also helps in extending the lifespan of the machine, preventing unnecessary wear and tear on individual elements.

How to Read the Parts Diagram

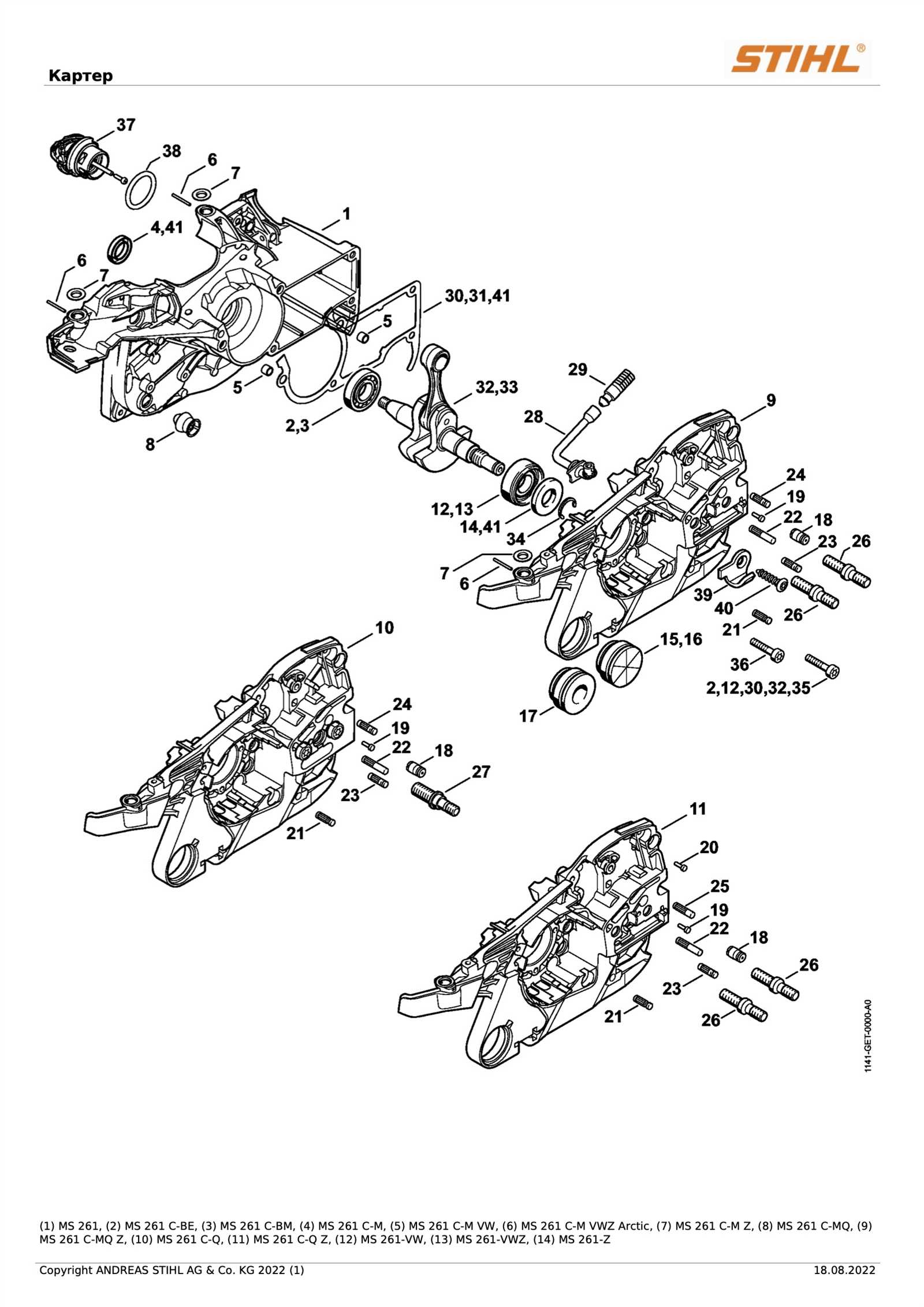

Understanding a visual guide for your chainsaw is essential for efficient maintenance. A well-structured illustration allows you to identify each component’s placement and function within the overall system. Being able to interpret these visual aids makes it easier to pinpoint issues and find the correct replacement parts when needed.

Identifying Key Components

The first step in reading a schematic is recognizing the major sections of the machine. Typically, these include the engine, cutting system, and control mechanisms. Each of these categories is represented with clear labels and sometimes numbers, which correspond to specific components. These parts are usually marked with unique identifiers, such as part numbers or labels, which help you match them to the correct replacement item.

Understanding the Layout and Connections

Next, pay attention to the layout and how the components are connected. Arrows, lines, or color coding may indicate the relationships between different parts. For example, a line connecting the engine to the fuel system shows how these elements work together. Understanding these connections ensures that you replace the right components and helps in reassembling the machine correctly after maintenance.

Common Issues and Replacement Parts

Every machine experiences wear over time, and the same applies to your chainsaw. Regular use can lead to issues with key components, which, if not addressed promptly, could affect the overall performance. Being able to identify these common problems early on helps you avoid more severe damage and ensures a smoother operation. Replacing worn-out parts with the correct components is crucial for maintaining efficiency and safety.

Frequent Problems and Causes

One of the most common issues is the deterioration of the cutting chain, which may become dull or damaged after extended use. Another frequent problem is fuel system clogging, often caused by debris or old fuel. If the engine is not starting properly, it could indicate issues with the ignition system or air filter. These problems are usually straightforward to diagnose and can be resolved by replacing the affected parts.

Choosing the Right Replacements

When replacing components, always opt for parts designed specifically for your machine to ensure compatibility and proper function. Whether it’s a new chain, air filter, or fuel line, selecting high-quality replacements will extend the life of your tool and prevent frequent repairs. Proper installation is just as important–following the manufacturer’s instructions ensures everything fits correctly and operates safely.