To ensure the optimal functioning of any machine, it’s essential to understand how its individual elements work together. By familiarizing yourself with the structure and role of each part, you can maintain and troubleshoot the equipment with ease. Proper knowledge of its construction helps avoid potential problems and boosts efficiency during operations.

Identifying the core components of the machine is the first step toward mastering its use. Each element plays a crucial role in the overall process, contributing to the smooth execution of tasks. Gaining insight into their design and function empowers operators to handle the device effectively and extend its lifespan.

With regular maintenance and careful attention to the individual components, you can keep the machine in top condition for long-term use. This knowledge ensures that potential issues are caught early, minimizing downtime and maximizing productivity.

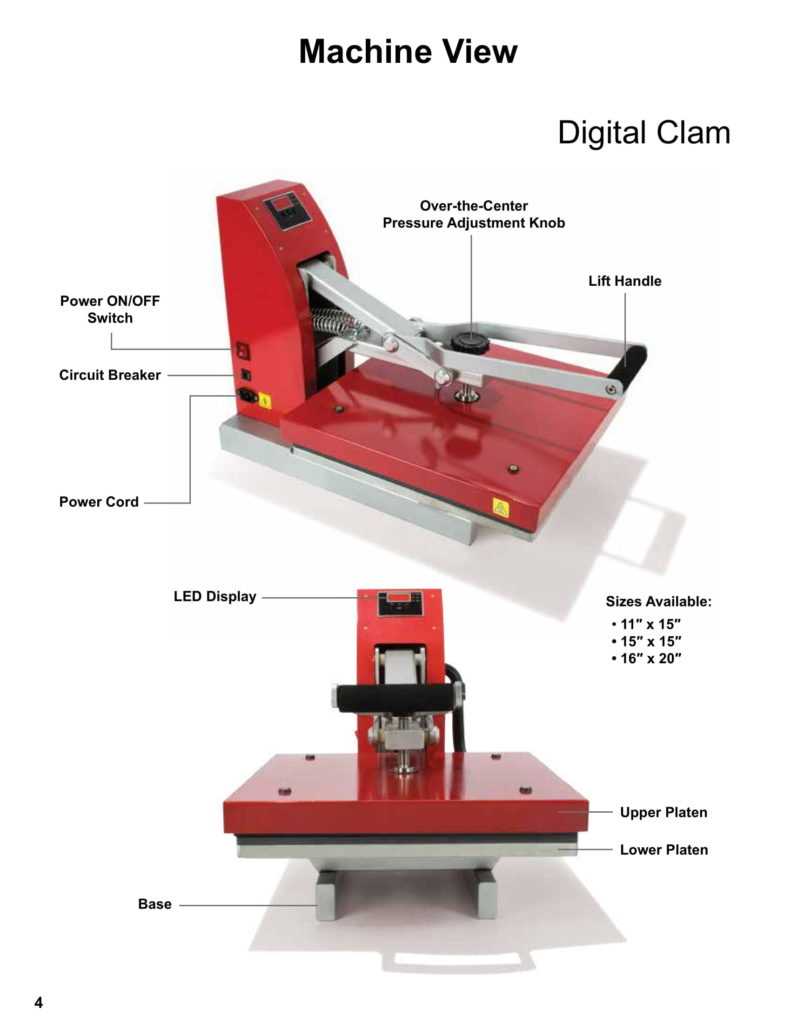

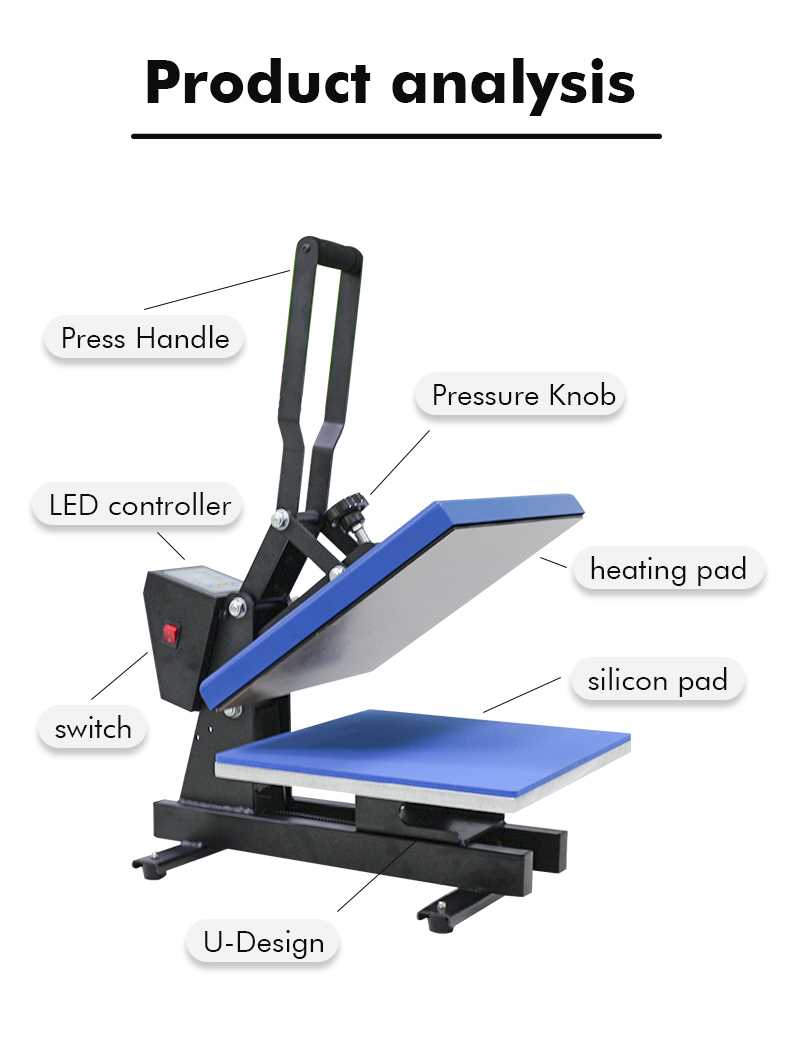

Key Components of a Heat Press

Understanding the essential elements of a machine is vital for effective operation and maintenance. Each part contributes to the overall performance, making it important to recognize their specific functions. This section highlights the core components, which are crucial for a successful and efficient operation.

Base and Platform

The base serves as the foundation, holding the entire system together. The platform provides a stable surface, ensuring consistent pressure and temperature distribution. These elements must be durable to withstand the pressure exerted during use and offer stability throughout the process.

Heating Element

The heating element is the heart of the operation, responsible for generating and maintaining the necessary temperature. It plays a vital role in transferring heat evenly to materials, ensuring that the desired result is achieved. Proper maintenance of this component is essential for maintaining performance.

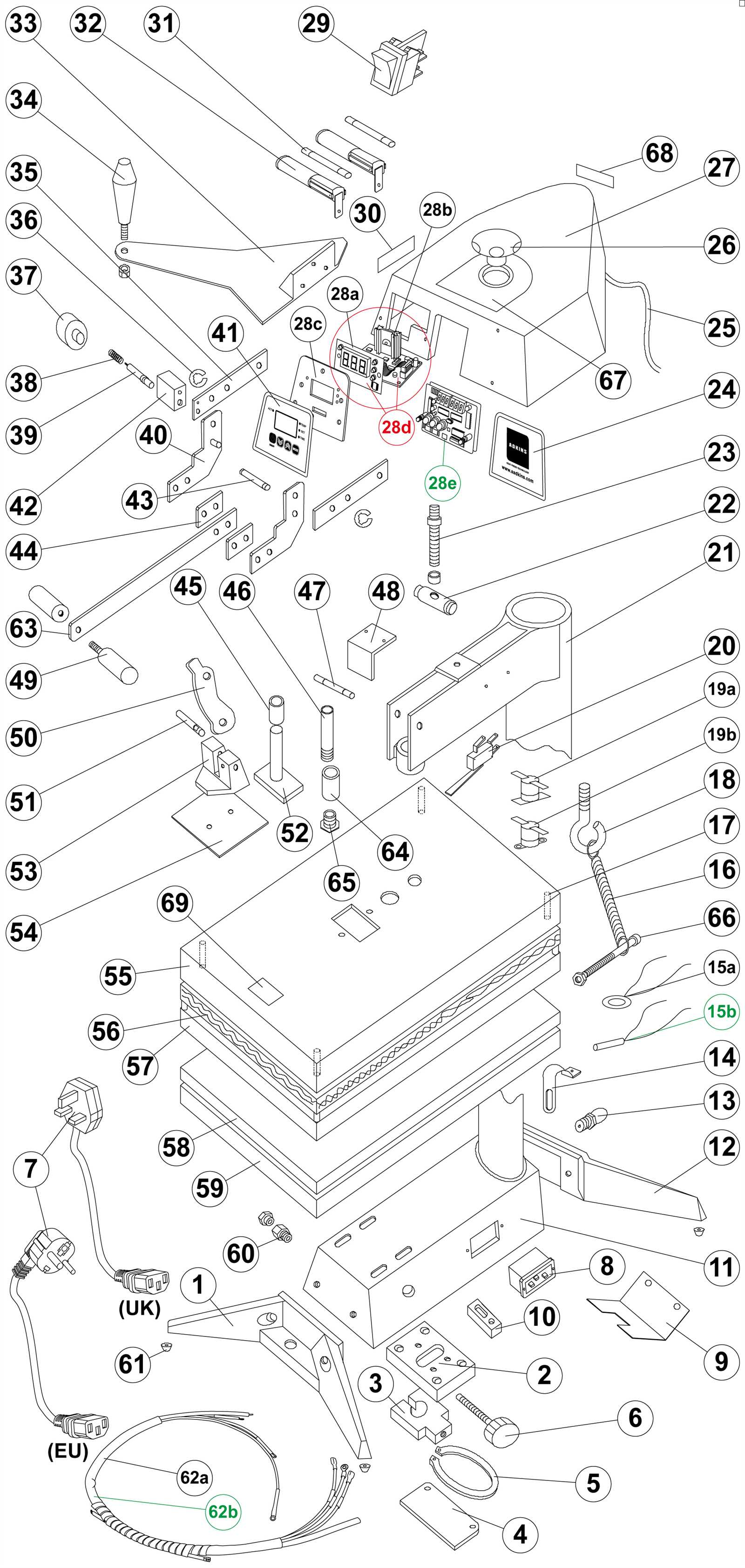

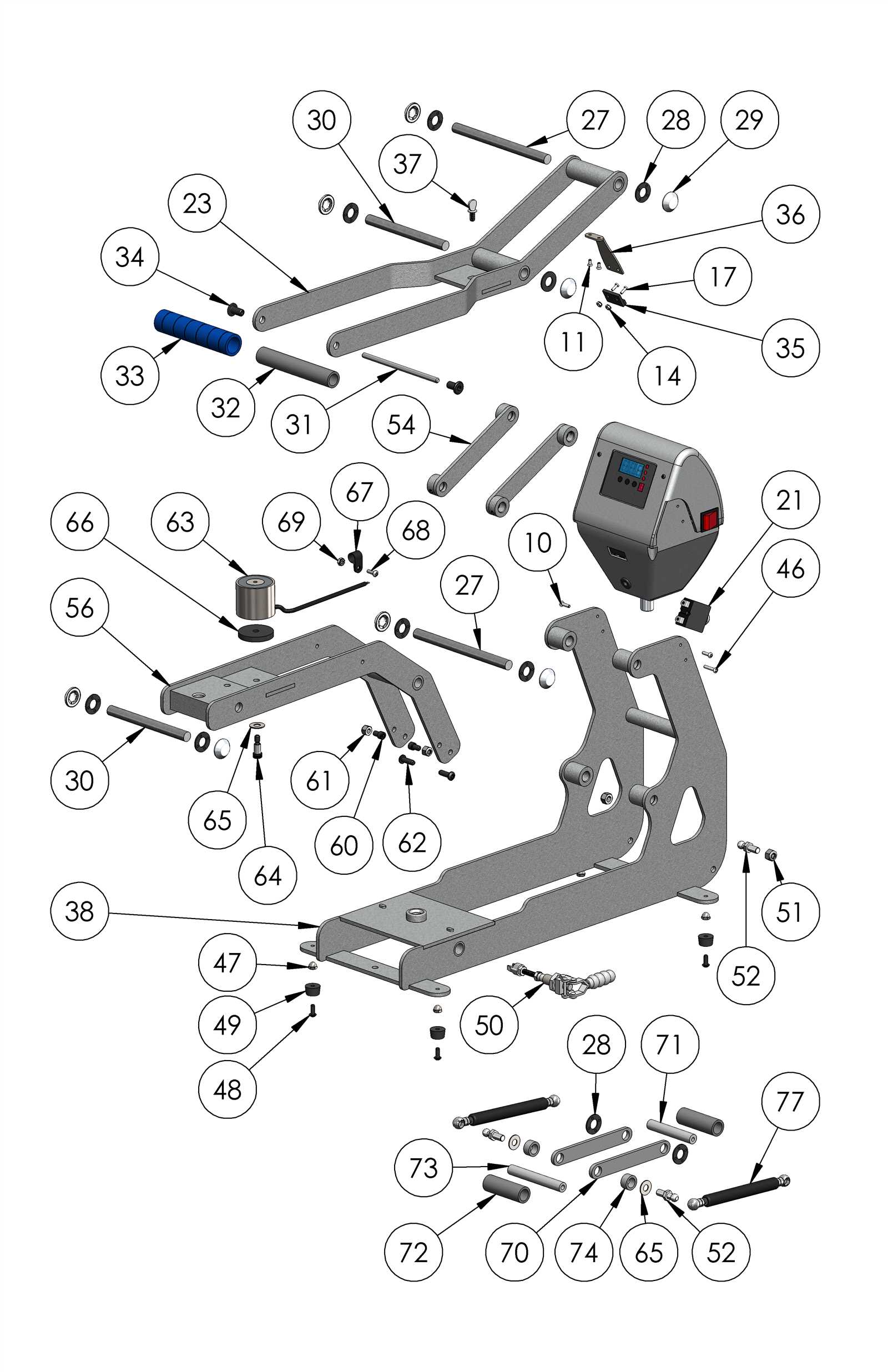

How to Identify Heat Press Parts

Recognizing the individual components of a machine is crucial for troubleshooting, maintenance, and enhancing its overall functionality. By carefully inspecting each part, operators can quickly detect issues, identify areas for improvement, and ensure optimal performance. This section will guide you in distinguishing the key elements of the system and understanding their roles.

The first step in identification is familiarizing yourself with the layout of the machine. Each component is strategically placed to perform a specific task, contributing to the efficiency of the entire process. Understanding the purpose of each section helps in recognizing them when inspecting or repairing the machine.

Once you have identified the key areas, regularly check them for wear and tear. Ensuring that every part is functioning as intended will prevent unnecessary breakdowns and extend the lifespan of your equipment.

Maintaining Your Heat Press for Longevity

Proper care and attention are essential for maximizing the lifespan of any equipment. Regular maintenance ensures that the system operates efficiently, reducing the likelihood of unexpected failures and costly repairs. By following a few simple steps, you can significantly extend the service life of your machine.

Regular Inspections

Consistent checks on the machine’s components are crucial to identify potential issues before they become serious problems. Look for signs of wear or damage, such as:

- Cracks or rust on metal surfaces

- Loose or worn-out connections

- Accumulation of dirt or debris

Cleaning and Lubrication

Maintaining a clean and well-lubricated machine is key to its smooth operation. Regularly wipe down surfaces and lubricate moving parts to prevent unnecessary friction and wear. Follow these tips:

- Use a soft cloth to remove any dirt or residue after each use

- Apply the appropriate lubricant to joints and hinges

- Ensure the heating elements are free from dust and debris