The system responsible for transferring power from the engine to the wheels is made up of several intricate components. Each piece plays a crucial role in ensuring smooth performance and handling. This system is vital for enabling the vehicle to move efficiently across different terrains.

To better comprehend how this complex mechanism works, it is important to examine the individual elements involved. From the rotating gears to the bearings and shafts, every part contributes to the overall function of the drivetrain, helping distribute torque to the appropriate wheels.

Recognizing the specific functions of these components not only aids in understanding their roles but also provides valuable insight into common mechanical issues. This knowledge is essential for maintenance, repairs, and improving vehicle longevity.

Key Components of the Drivetrain System

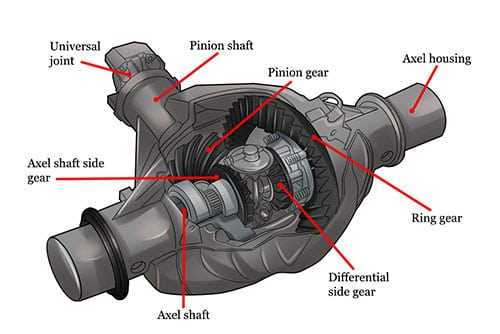

The mechanism responsible for transmitting rotational power from the engine to the wheels is composed of several essential elements. These components work in harmony to ensure that the vehicle operates smoothly, especially when navigating challenging conditions. Understanding each part’s role is crucial for maintaining optimal performance and addressing any mechanical issues.

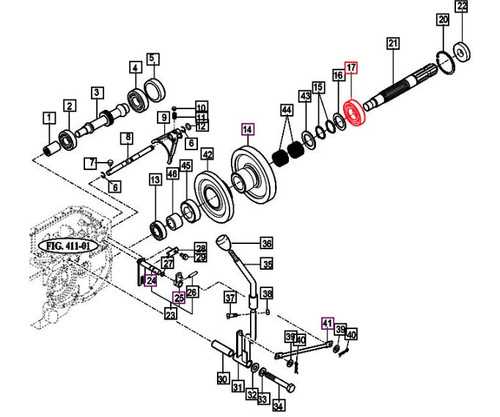

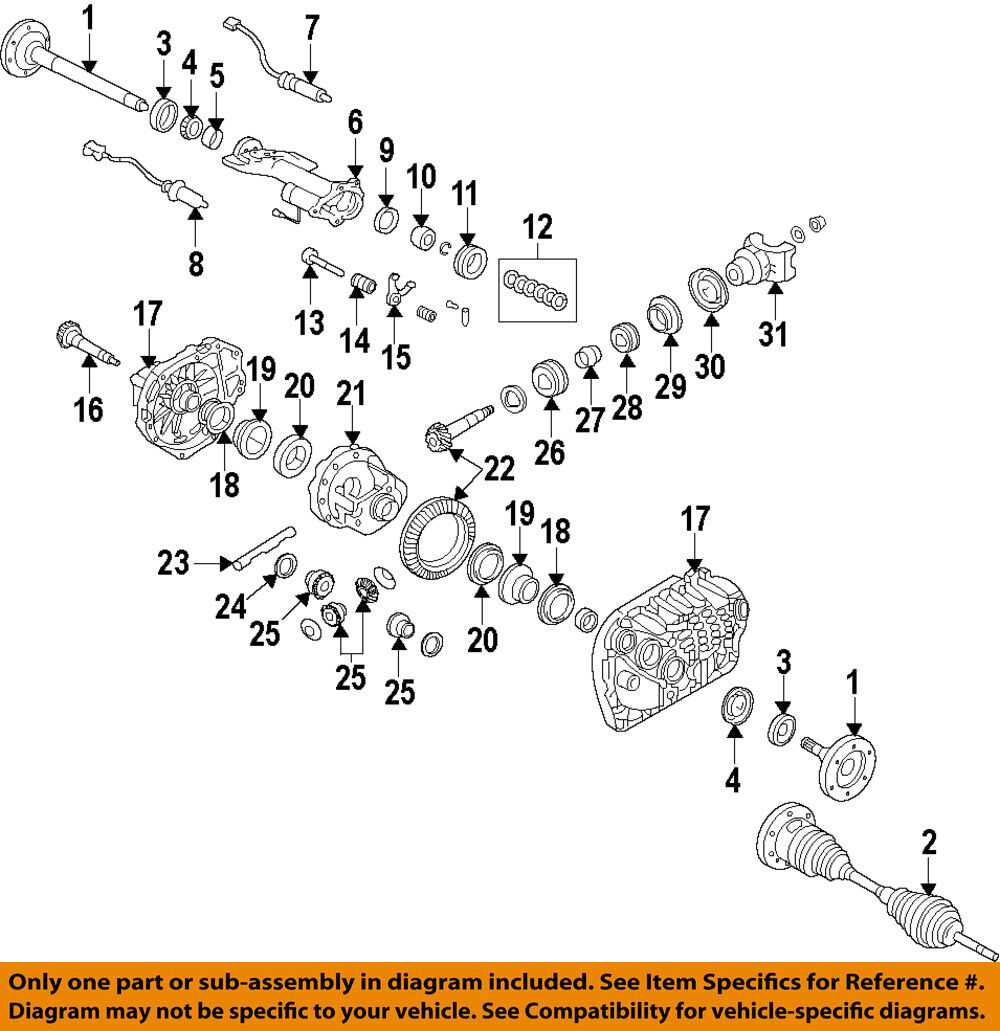

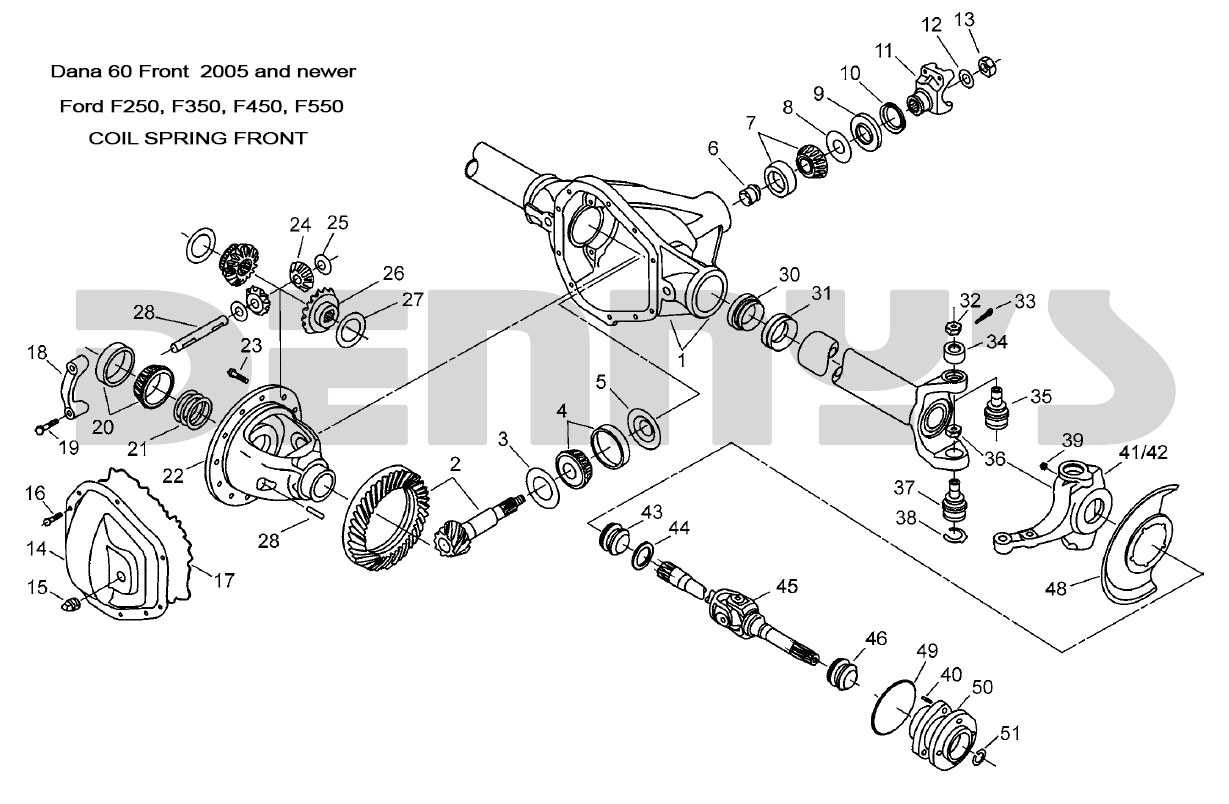

Gears and Rotating Shafts

At the heart of the system are the gears and shafts, which manage the distribution of torque. These elements rotate in precise motion to transfer power, ensuring the vehicle’s wheels turn at the appropriate speeds. Gears are carefully designed to withstand heavy forces, while shafts connect various parts, allowing energy to flow efficiently across the system.

Bearings and Housing

Bearings help reduce friction between moving parts, enabling smooth rotation without excessive wear. The housing, a robust casing that surrounds these components, protects them from dirt and debris while keeping everything in place. Together, bearings and housing ensure that the system functions effectively, even under strain.

How the Drivetrain System Functions

The primary goal of the drivetrain is to ensure that power from the engine is efficiently transmitted to the wheels, allowing the vehicle to move. This process involves a series of interconnected components that work together to adjust the speed and torque sent to each wheel, depending on driving conditions. The system ensures that all wheels receive the appropriate amount of force for optimal handling, especially when navigating turns or uneven surfaces.

In a typical setup, power flows from the engine through a series of shafts, gears, and other mechanical elements that help manage torque distribution. These parts engage and disengage as needed, adapting to changes in terrain and driving demands. This intelligent transfer of power helps maintain stability and traction, improving the overall driving experience.

Common Issues in Drivetrain Systems

Even with regular maintenance, drivetrain systems can experience various issues that may affect their efficiency and performance. These problems often stem from wear and tear on key components, misalignment, or inadequate lubrication. Recognizing these issues early can prevent further damage and costly repairs, ensuring that the vehicle remains reliable on the road.

Excessive Wear and Tear

Over time, the constant rotation of gears, shafts, and bearings can lead to significant wear, particularly in high-stress areas. This wear can result in poor power transfer, noisy operation, or even complete failure of crucial components. Routine inspections are essential for identifying worn parts before they cause serious damage.

Improper Lubrication

Lubricants play a critical role in reducing friction and preventing parts from overheating. Insufficient lubrication or using the wrong type of fluid can cause metal parts to grind against each other, accelerating wear. This issue often leads to overheating, resulting in system failure or damage that could require costly repairs.