In the world of mechanical systems, understanding how individual elements work together is essential for maintenance and repair. Detailed illustrations provide a clear view of how each component interacts, helping technicians diagnose issues efficiently. A thorough knowledge of these visual guides allows users to identify and address potential failures more effectively.

Visual schematics are invaluable tools when it comes to understanding the intricacies of complex machinery. By offering a detailed representation, these visuals help clarify the structure and functionality of key components, ensuring better-informed decision-making during servicing or troubleshooting.

Knowing how to interpret these detailed images can save time and prevent unnecessary errors. A proper understanding leads to smoother repairs, longer-lasting machinery, and enhanced performance. By focusing on each individual part’s role and interconnection, one can achieve a comprehensive view of the entire system’s operation.

Understanding Mechanical Components

Every mechanical system relies on a variety of interconnected elements, each contributing to its overall performance. Understanding the role of each component within a system is essential for efficient operation and maintenance. By breaking down the function of each part and its relation to others, technicians can better troubleshoot issues and ensure longevity.

Key Elements in the System

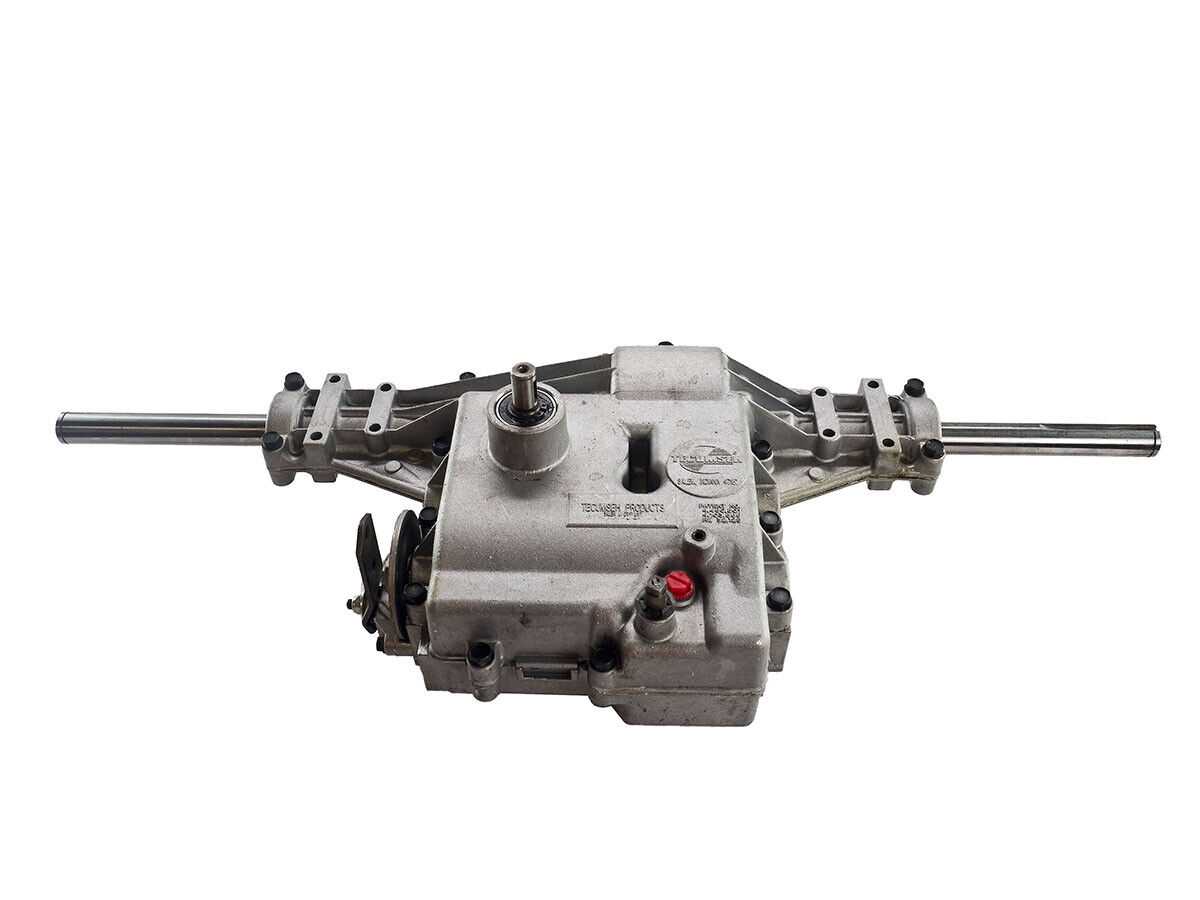

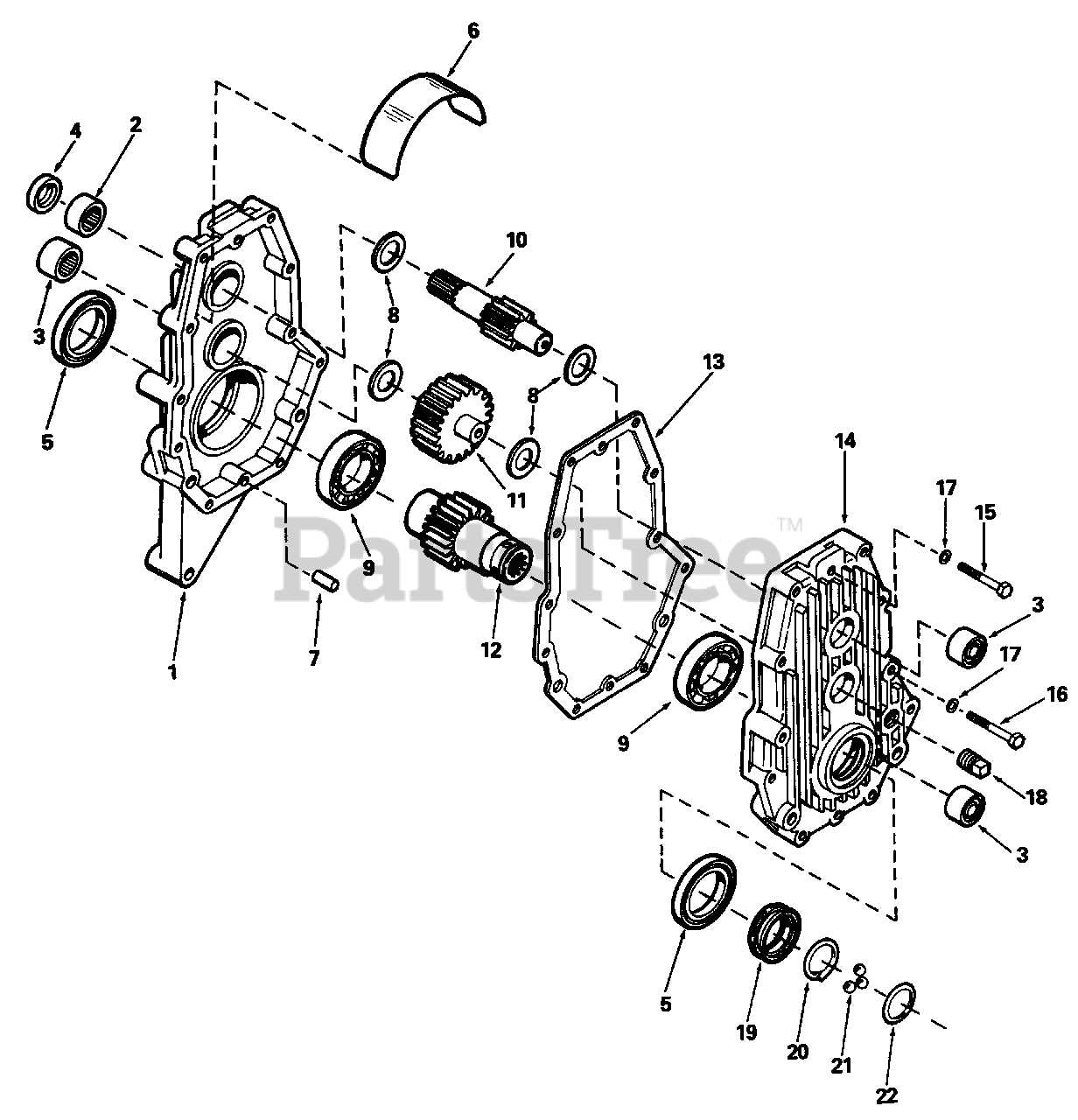

In a well-designed mechanism, the core components work seamlessly together to transmit power, facilitate movement, and maintain stability. The heart of the system typically involves gears, shafts, and levers, each playing a specific role in transferring force. These elements must be carefully calibrated and maintained to prevent wear and ensure optimal functionality.

How Components Interact

Each element interacts with others to create smooth operation. For instance, gears mesh to transfer rotational motion, while shafts support and guide the movement of other parts. Understanding how these elements influence each other allows for precise adjustments and repairs. Effective maintenance hinges on recognizing these interdependencies, which can prevent larger issues down the line.

How to Read Mechanical Layouts

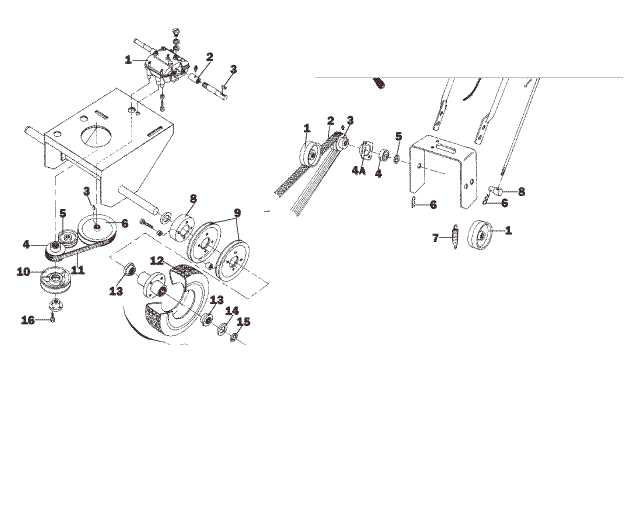

Interpreting technical drawings requires an understanding of the visual language used to represent complex systems. These illustrations convey the structure and function of various components, often showing how they interact with each other. To effectively read and use these images, it’s important to familiarize yourself with the key symbols, connections, and notations present in the guide.

Identifying Key Symbols

Each part in a schematic is represented by a unique symbol, which is a shorthand for its physical form. Recognizing these symbols allows for quick identification of components, making it easier to follow their connections and interactions. For example, gears are often depicted as circles with teeth, while shafts might be shown as simple lines with arrows indicating their direction of movement.

Following the Connections

The next step is to understand how these elements are linked together. Lines and arrows are commonly used to represent the flow of motion, force, or energy between parts. Paying attention to these connections will give you insight into how the entire system operates. It’s crucial to follow the path from one part to another to fully comprehend the mechanical flow within the system.

Common Issues with Mechanical Components

Mechanical systems, over time, can experience wear and tear, leading to various problems that affect performance. Recognizing these issues early is crucial for effective repairs and avoiding further damage. Common problems often stem from improper lubrication, misalignment, or the degradation of key elements, which can cause the entire system to malfunction.

Wear and Tear on Key Elements

One of the most common issues is the gradual wear of moving components. Gears, shafts, and other elements can experience friction, leading to surface degradation. This can cause slipping, loss of efficiency, or even complete failure if left unaddressed. Regular inspection is vital to detect these early signs of wear and replace parts before they cause more serious problems.

Misalignment and Improper Assembly

Another frequent issue arises from misalignment or improper assembly during the initial installation or repair. Even slight deviations can lead to inefficient performance, excessive vibration, or even damage to surrounding components. Ensuring precise alignment during assembly is key to maintaining a smooth operation and extending the lifespan of the system.