Proper maintenance and timely repairs are essential for the longevity and optimal performance of your spray equipment. Whether you are a professional or a DIY enthusiast, understanding the inner workings of your machine will help you identify potential issues and address them before they escalate. By familiarizing yourself with the key components, you can ensure smooth operation and avoid costly breakdowns.

In this guide, we will explore the different sections of a sprayer, helping you recognize parts that may need attention. You’ll gain insight into how to interpret technical diagrams, making it easier to identify components, troubleshoot, and replace damaged items. With the right knowledge, you can efficiently keep your equipment in top shape.

From small adjustments to more extensive repairs, having a clear understanding of your sprayer’s structure will empower you to handle any challenge that arises. Maintaining the equipment not only improves its performance but also extends its working life, making your investment more cost-effective in the long run.

Understanding Key Components of Your Sprayer

Every spray machine consists of several essential components that work together to ensure smooth operation. Recognizing and understanding these parts is critical to troubleshooting, maintenance, and repairs. Familiarity with the individual elements will allow you to make informed decisions about replacements or adjustments, ultimately improving the performance and efficiency of your equipment.

Critical Elements for Optimal Performance

Among the most important components of a sprayer are the pump, spray nozzle, hose, and trigger mechanism. These parts are directly responsible for the delivery and precision of the spray, which is vital for achieving professional results. The pump provides the necessary pressure, while the nozzle controls the pattern and flow of the material being sprayed. The hose ensures a smooth transfer of liquid, and the trigger allows for controlled operation.

Maintenance Considerations for Longevity

Regular inspection and maintenance of these key elements will extend the lifespan of your equipment. Components such as seals and filters should be checked periodically for wear, as damage to these parts can lead to leaks or inefficient spraying. Proper cleaning and lubrication also play a significant role in keeping these essential parts functioning at their best, preventing costly repairs down the line.

How to Use the Parts Diagram Effectively

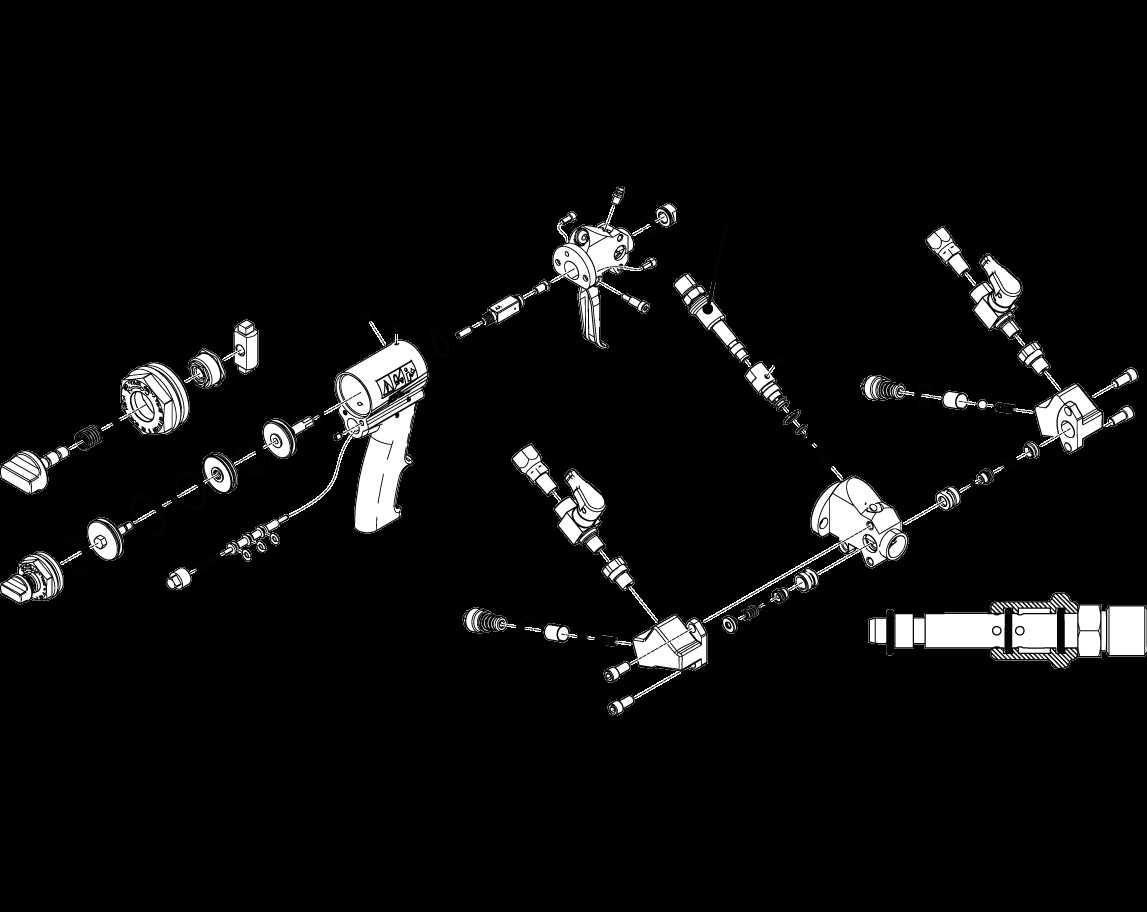

To ensure smooth repairs and maintenance, understanding how to read and interpret technical diagrams is essential. These visual guides provide a clear representation of all the components of your equipment, making it easier to identify parts that need attention. By using these resources effectively, you can save time and avoid mistakes during disassembly, replacement, or reassembly.

Step-by-Step Guide to Reading the Diagram

Start by familiarizing yourself with the overall layout of the diagram. Identify the key sections and locate the components you need to examine. Each part is typically numbered or labeled, which will help you correlate with the corresponding items in your manual or catalog. Pay close attention to the placement and connections between parts, as this will be crucial when putting everything back together.

Using the Diagram for Troubleshooting

When something goes wrong with your equipment, the diagram is an invaluable tool for pinpointing the source of the problem. If you encounter issues like leaks, poor performance, or irregular spray patterns, consult the visual representation to check the related components. By knowing exactly where each part fits and functions, you can quickly identify what needs to be repaired or replaced. Efficient use of the diagram can significantly reduce downtime and improve repair accuracy.

Common Repairs with Your Sprayer

Even the most durable equipment can encounter issues over time. Understanding the most common repairs allows you to address problems quickly and efficiently, minimizing downtime and ensuring optimal performance. By recognizing signs of wear or malfunction early, you can make repairs before they lead to more serious complications.

Replacing Worn Seals and Gaskets

One of the most frequent repairs is replacing worn seals and gaskets. These components are crucial for preventing leaks and maintaining the pressure necessary for proper function. Over time, exposure to chemicals or regular use can cause these parts to degrade. Regular inspections can help identify any cracks or wear, allowing for timely replacement before more significant issues arise.

Fixing Clogged or Damaged Nozzles

Another common issue is clogged or damaged nozzles, which can lead to uneven spray patterns or a decrease in output. Dirt, debris, or dried material often block the nozzle, affecting the spray efficiency. Cleaning or replacing the nozzle can resolve these problems. If the nozzle is damaged, it is essential to replace it with the correct size and type to ensure proper operation.