When it comes to maintaining and repairing machinery, having a clear view of the individual elements is crucial. Knowing how each component works together ensures efficiency and extends the machine’s lifespan. A thorough breakdown of the core elements can make the difference between effective upkeep and costly mistakes.

Understanding the layout and functions of various parts is essential for proper diagnostics and timely repairs. Whether you’re an experienced technician or a casual user, having access to a detailed map of all critical components helps avoid confusion and errors during maintenance procedures.

Being familiar with each part’s role and connection within the system enables more informed decisions. Familiarizing yourself with these visual guides not only aids in everyday repairs but also enhances the overall performance of the equipment in the long run.

Understanding Key Components

To maintain the optimal performance of any machinery, it’s essential to understand the individual elements that work together. Each critical component has a specific role, and knowing how they interact helps ensure smooth operation and easy troubleshooting. A comprehensive grasp of the main parts allows for quicker identification of issues and more efficient repairs.

The engine, drive system, and hydraulic components are among the most vital elements in any piece of heavy equipment. They contribute to the overall functionality, whether in powering the system, controlling movement, or supporting various mechanical functions. Understanding how these systems connect and operate enhances your ability to maintain or repair the machine when needed.

In addition to these main systems, other supporting features such as electrical and control mechanisms play significant roles. These parts work in tandem with the more prominent components, ensuring seamless operation and maximum performance. A well-rounded understanding of each part’s function is key to achieving long-term reliability and avoiding unnecessary downtime.

Essential Elements for Maintenance and Repair

To ensure long-term functionality and minimize downtime, it is vital to focus on the key components that require regular attention. Regular maintenance of these elements helps prevent failures and enhances overall performance. Understanding the most critical areas for upkeep allows for more effective repairs and ensures smooth operation throughout the machinery’s life cycle.

Engine and Power Systems

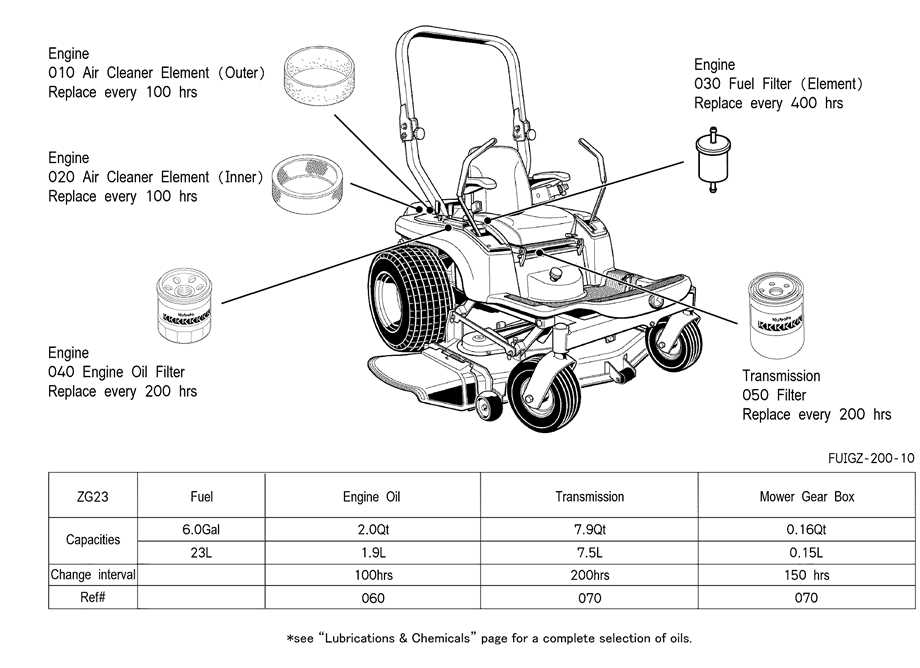

The engine is the heart of any machine, and its maintenance is crucial for reliable performance. Regular checks of oil levels, filters, and cooling systems are essential for avoiding overheating and ensuring optimal fuel efficiency. Proper care of these systems not only enhances performance but also extends the life of the machinery.

Hydraulic and Drive Systems

The hydraulic and drive systems are equally important for the machine’s ability to perform under load. These systems are responsible for movement and power transmission, making them essential for every task. Regular inspection of hoses, valves, and seals ensures that there are no leaks or pressure drops, which could compromise the functionality of the entire system.

Maintaining these key components will prevent costly repairs and extend the machinery’s useful life, keeping it performing at its best over time.

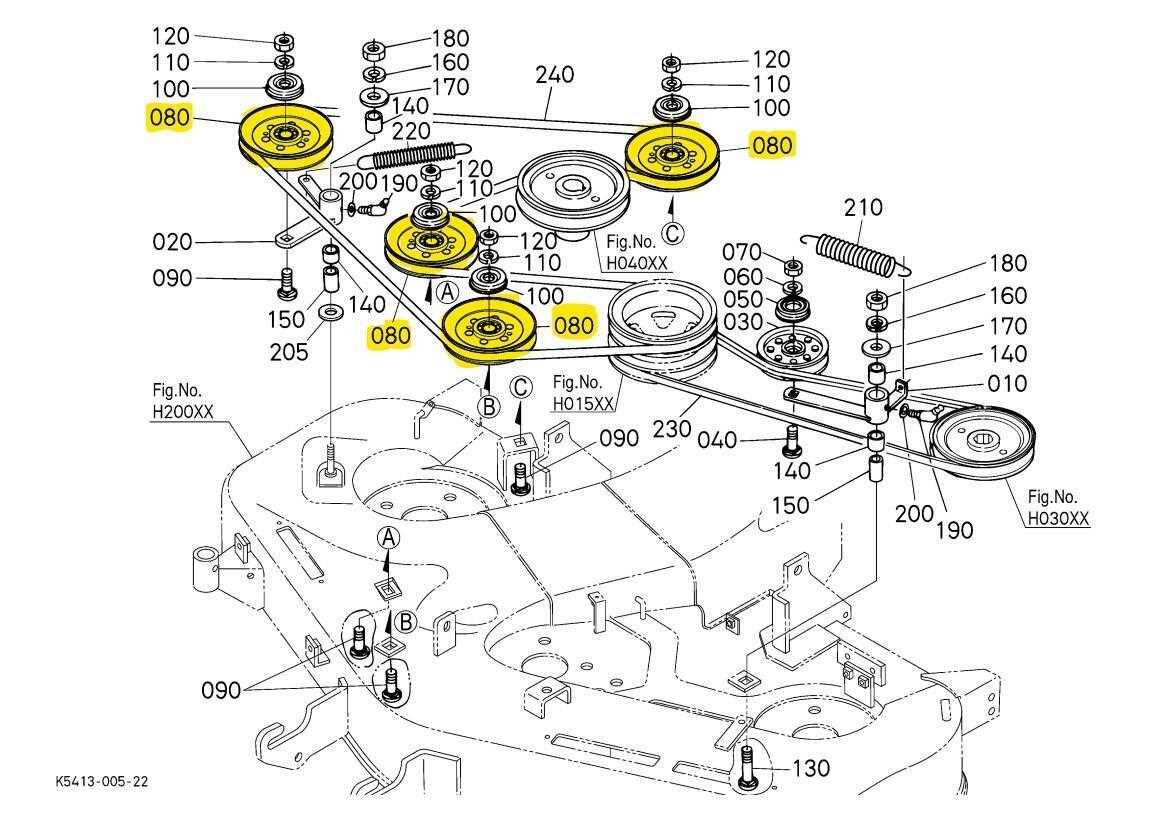

How to Use the Components Breakdown

Understanding how to navigate a breakdown of essential components is key to performing effective maintenance and repairs. These visual guides provide a clear representation of how each element fits into the system, making it easier to identify, replace, or troubleshoot individual parts. By knowing how to use these guides, users can quickly locate and address issues, reducing downtime and improving overall efficiency.

The first step in using such a guide is familiarizing yourself with the layout and the labeling system. Components are usually arranged logically, with the most critical systems highlighted first. By understanding the structure and labeling, users can easily find the part they need to inspect or replace.

Additionally, it’s important to cross-reference these guides with the machine’s manual or other technical documents. This will ensure that the correct parts are being worked on and prevent errors during repairs. Understanding each component’s role within the system allows for better decision-making and more efficient repair processes.